Makes Money-Losing Job a Winner for Mecon Industries

(SCARBOROUGH, ONTARIO, CANADA) – Difficult jobs can be a reminder why it’s good to keep up with the latest cutting-tool advances. For Mecon Industries (Scarborough, Ontario, Canada), new Beyond™ tooling from Kennametal was the difference between potential failure on a job no one could cut to delivering the part on time as promised.

Beyond is Kennametal’s newest line of tooling, a complete portfolio of new grades and geometries for cutting cast-iron, steel, stainless steel, and high-temperature alloys. Beyond tools are engineered to increase metal-removal rates and extend tool life, significantly in many cases. Says Ujjwal (UJ) Baid, Kennametal Senior Product Manager, “Depending on the application, field tests have shown anywhere from 30% to 300% improvement.”

Beyond is Kennametal’s newest line of tooling, a complete portfolio of new grades and geometries for cutting cast-iron, steel, stainless steel, and high-temperature alloys. Beyond tools are engineered to increase metal-removal rates and extend tool life, significantly in many cases. Says Ujjwal (UJ) Baid, Kennametal Senior Product Manager, “Depending on the application, field tests have shown anywhere from 30% to 300% improvement.”

Supporting Beyond’s improved levels of performance are a number of technology features. Beyond tools feature a new post-coat surface treatment that improves edge toughness, reliability, and depth-of-cut notch resistance, and micro-polishes the surface to reduce friction and workpiece sticking (BUE). A fine-grained alumina layer accommodates increases in cutting speed, improving productivity.

All the new Beyond inserts are CVD (chemical vapor deposition) coated, but where conventional CVD coatings are under tensile stress, Beyond inserts undergo a proprietary post-coat treatment on all surfaces to reduce this stress, improving coating adhesion and reducing micro-chipping. “More uniform and reliable wear of the cutting edge results in improved and more consistent tool life,” says Kent Mizgalski, Manager, Global Lathe Systems Engineering at Kennametal. “Smoother surfaces also lower frictional forces, another factor that expands applications and permits higher cutting speeds. Together with the right geometry, we’ve seen big improvements in chip control and tool life in both internal and field tests.”

Cutting Tool Steel

Encounter tool steel and you’ll find you need more of everything – more power, more performance, and maybe most important, more knowledge. Tool steel grades are engineered for extreme levels of toughness and durability. Bruno Cecchini, Plant Manager at Mecon Industries, Scarborough, Ontario, knows this, and has known it for more than 45 years. One of the original employees when Mecon opened its doors in 1962, Cecchini has seen Mecon develop two specialties – manufacturing coil-handling equipment such as coil reelers, unreelers, and coil straighteners for the metal fabricating industries, and providing press brake dies.

Encounter tool steel and you’ll find you need more of everything – more power, more performance, and maybe most important, more knowledge. Tool steel grades are engineered for extreme levels of toughness and durability. Bruno Cecchini, Plant Manager at Mecon Industries, Scarborough, Ontario, knows this, and has known it for more than 45 years. One of the original employees when Mecon opened its doors in 1962, Cecchini has seen Mecon develop two specialties – manufacturing coil-handling equipment such as coil reelers, unreelers, and coil straighteners for the metal fabricating industries, and providing press brake dies.

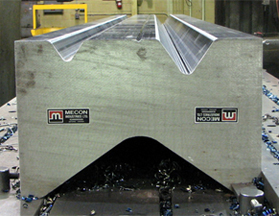

Press brake dies are tooling used for bending metals into predetermined shapes. Bending large or thick metal plate depends on the size of the die opening, the strength of the die, the shape of the punch, and the tonnage of the press brake. “We design, manufacture, and test custom press brake tooling for bending any material thickness and material type, from steel and aluminum to exotics like zircalloy,” he says. “Our planers range in length from 12 to 30 feet long. We also have a 200-ton hydraulic press for tryouts. With our experience, we can provide a single-hit tool that combines bends and reduces the number of hits to complete a part. We also stock a line of standard tools for off-the-shelf delivery.”

Mecon customers can order the material type, thickness, and hardness of the dies they want to match the tonnage of their press brake equipment and the jobs they want to handle. If not otherwise specified, Mecon makes press brake tooling from pre-hardened die steel at 265 to 280 Brinell.

Under the Gun

Recently, Mecon faced a significant challenge. The customer, Hodgson Custom Rolling, required a die 14 feet long and 22 inches wide with an 18-inch die opening for bending two- to four-inch-thick plate. The rough die steel block arrived so tough that the tooling Mecon traditionally used on its planing equipment lasted for three strokes before failing.

Recently, Mecon faced a significant challenge. The customer, Hodgson Custom Rolling, required a die 14 feet long and 22 inches wide with an 18-inch die opening for bending two- to four-inch-thick plate. The rough die steel block arrived so tough that the tooling Mecon traditionally used on its planing equipment lasted for three strokes before failing.

Remember that dies are tooling used by customers to make the products their customers require, so when die customers say they need their tools, they’re not fooling around. “We were really under the gun,” Cecchini describes. “We had promised a delivery date, and we had a 20,000-pound piece of steel at 35 Rockwell (which translates to 323 Brinell, well above Mecon’s standard range) we couldn’t cut.”

Normally, Mecon’s planing machines are the workhorses of their die business, cutting at a maximum 200 feet per minute, Cecchini says. Lowering speeds didn’t help, the tooling they traditionally used was failing after three strokes, and the range of tooling providers they sought help from “pretty much had the same results,” in Cecchini’s words.

Until Dan Atwell, Metalworking Sales Engineer with Kennametal (Latrobe, PA), came to Mecon’s plant with samples of the company’s new Beyond™ line of inserts. Atwell brought samples of the new Beyond grade KCP40. According to Mecon machine operator David Filipovic, the old tooling was failing after three strokes, and even on Mecon’s standard brake die steel, inserts would last only 15 or 20 minutes per edge before failure. “We put Kennametal’s new Beyond grade KCP40 on our planer mill and the final parameters we were running after the testing were 0.750-inch depth of cut, 200 surface feet per minute, and .032 feedrate,” he says “We were able to run 14 foot planer strokes for approximately 80 minutes an edge.”

Until Dan Atwell, Metalworking Sales Engineer with Kennametal (Latrobe, PA), came to Mecon’s plant with samples of the company’s new Beyond™ line of inserts. Atwell brought samples of the new Beyond grade KCP40. According to Mecon machine operator David Filipovic, the old tooling was failing after three strokes, and even on Mecon’s standard brake die steel, inserts would last only 15 or 20 minutes per edge before failure. “We put Kennametal’s new Beyond grade KCP40 on our planer mill and the final parameters we were running after the testing were 0.750-inch depth of cut, 200 surface feet per minute, and .032 feedrate,” he says “We were able to run 14 foot planer strokes for approximately 80 minutes an edge.”

Getting approximately 500 strokes per corner and over five hours tool life per insert on 35 Rockwell tool steel was “unbelievable” in Cecchini’s words. “The chips were nice and smooth,” confirms Bruno Cecchini. “With five inserts, we were able to remove more than 4,000 pounds of chips on this job.”

Was Mecon able to deliver on time? “Without the use of these new Beyond tools, we would have lost money on this job,” answers Mecon president David Foscarini.

“We invited other tooling suppliers back in to see how these tools cut. The only word for it was they were surprised.”

“Dan brought in two inserts for us to try and we only needed to test one,” adds Bruno Cecchini. “It kept us going.” High praise, maybe the highest, when making money cutting tool steel is the situation you’re facing.

“Dan brought in two inserts for us to try and we only needed to test one,” adds Bruno Cecchini. “It kept us going.” High praise, maybe the highest, when making money cutting tool steel is the situation you’re facing.

Kennametal Inc. (NYSE: KMT) is a leading global supplier of tooling, engineered components and advanced materials consumed in production processes. The company improves customers’ competitiveness by providing superior economic returns through the delivery of application knowledge and advanced technology to master the toughest of materials application demands. Companies producing everything from airframes to mining equipment, from medical implants to oil wells and from turbochargers to motorcycle parts recognize Kennametal for extraordinary contributions to their value chains.

Kennametal Inc., Latrobe, PA; 800.446.7738.