Mecon offers a variety of services and materials for your metal handling needs:

- APEO Certificate of Authorization to provide Professional Engineering services

- Manufacturing consulting, process or machine specification, design, feasibility studies, etc.

- Extensive design with computer (SolidWorks and CADKEY software)

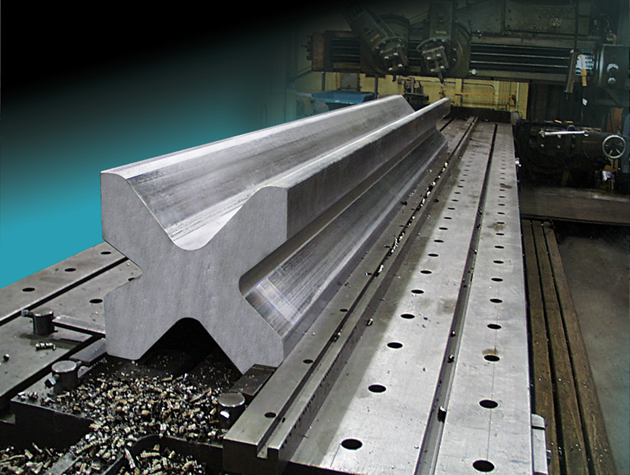

General Machining

- CNC Double Column Machining Center

- Horizontal and vertical milling

- CNC milling

- Planing to 30 feet

- Turning to 28″ diameter x 10 feet

- CNC turning

- Drilling

- Cylindrical and surface grinding

Fabricating

- Flame cutting

- Forming

- MIG, TIG, stick welding

- Fabrications to 10 tons in weight

- Shearing to 0.75″ x 96″

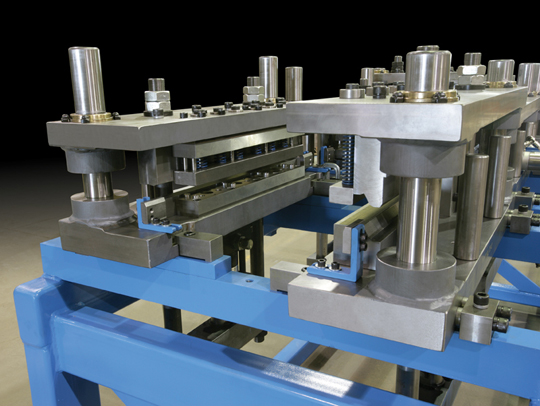

- Multiple hit dies

- Matched shut height tools

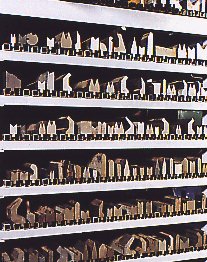

- Custom tooling (for steel, stainless, aluminum, etc.): design, construction, and testing

- Press brake accessories: angles, bolsters, spacers, etc.

- Repairs to dies, rails, clamps, bolsters

- Standard tools in stock

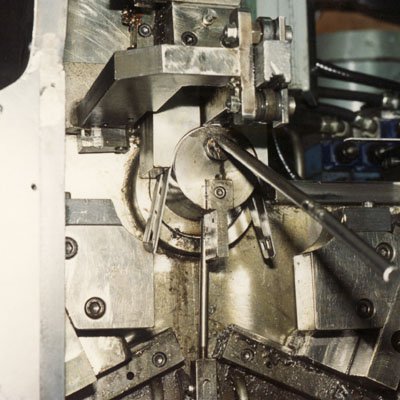

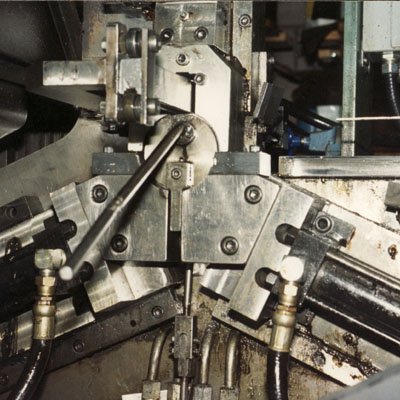

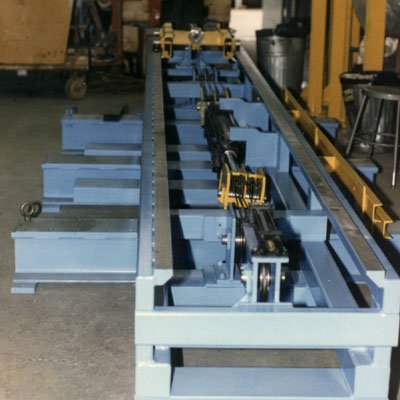

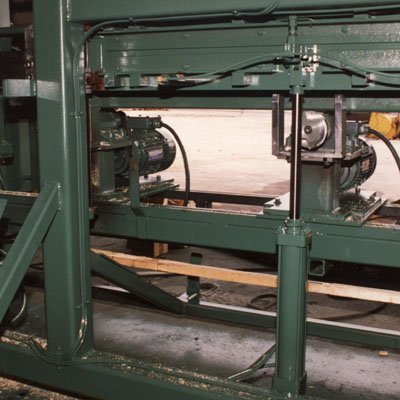

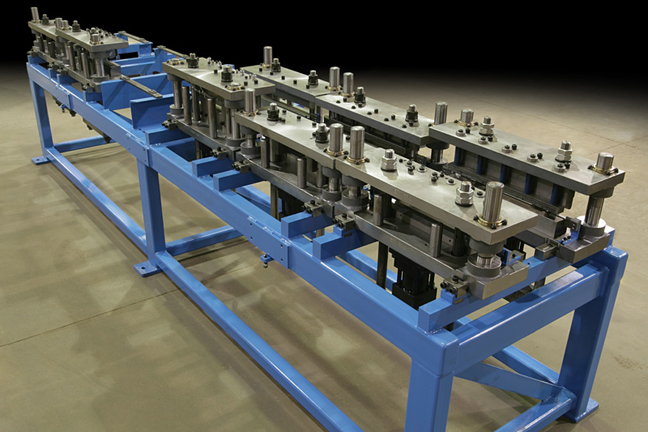

Coil Processing Machines

- Capacity to 60,000 pounds standard

- Coil cars, uncoilers, straighteners

- Coil cradles, coilcradle-straighteners

- Precision electronic roll feeds

- Threading systems

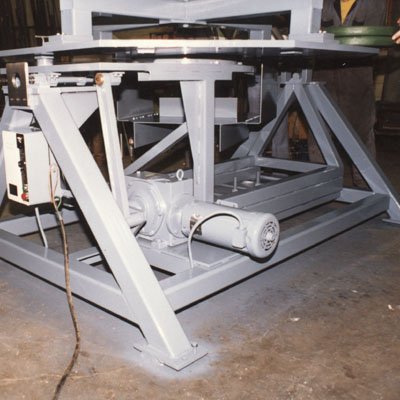

Custom Built/Rebuilt Machinery

- Design and manufacture of special-purpose machines

- Recondition and alter existing machines

- Retrofit updated components

Equipment Toolbox:

CNC MACHINING CENTERS:

Monforts-Starvision CNC Double Column Machining Center

- 1”x 78.4” work table

- x/y/z axis travel 126” x 90.5” x 39.4”

- table load 33,000 lbs.

- 40 Tool magazine

- Spindle nose to table 5.9”~ 45.3”

- Spindle 4,500rpm

- Programmable 90 Degree Milling Head 3,000rpm

- Fanuc 31iMB control1

Awea MB1600 Vertical Machining Center

- 8´x 31.5”, work table

- 24 tool magazine

- Fanuc iM control

- Automatic duel pallet system

Lead well MCV 760XLD Vertical Machining Centre

- 30” x 20” x 20” work travel

- 24 station automatic tool changer

- Fanuc OMA control

Lead well MCY 1300D Vertical Machining Centre

- 52” x 30” x 22” work travel

- 20 station automatic tool changer

- Fanuc OMA control

Topwell 5VK Turret Mill CNC ready Anilan 1100 Control

- 10” x 50” work table

Topwell TOJ

- 105 CNC ready Anilan 1100 Control

- 13” x 59” work table

CNC LATHES:

PBR CNC Lathe

- 24” diameter swing

- 160” between centers

- 8 tool turret

- Fagor 8050 TC teach control

Mori Seiki TL5 CNC Lathe

- 24” diameter swing at chuck

- 80” between centers

- 8 tool turret

- GE Fanuc series OT control

Lead well Model LTC 20 CPL Lathe

- 47” diameter swing at chuck

- 40” between centers

- 8 tool turret

- Fanuc OTF control

HORIZONTAL BORING MILLS:

CNC Toss

- 5 1/8” diameter spindle

- 6” x 70.91” rotary table

- 42” vertical travel

- 7” cross travel

- 15 tool changer

- Heidenhain TCN 426 CB

- 5 + 1 axis CNC system

Shibaura

- 5 1/8” diameter spindle

- 100” x 70” x 51” travel

- 48” x 100” table

- Universal tool attachment

Wotan

- 12” diameter spindle

- ” x 64” x 54 ¾” travel

- Power rotary table 55 ¼” x 48 ¾”

- Universal spindle attachment

PBR

- 3 ½” diameter spindle

- 60” x 48” x 57” travel

- Power rotary table 37” x 47”

- Universal spindle attachment

Gidding & Lewis

- 3” diameter spindle

- 52” x 36” table

- Facing and boring head

- Rotary table

PLANERS:

G.A. Gray

- 3 heads

- 42” x 45” x 12ft

- table width 38”

Gidding & Lewis open side

- 3 heads

- 42” x 34” x 16ft

- table width 32”

G.A. Gray open side

- 3 heads

- 36” x 36” x 23ft

- table width 36”

Cincinnati

- 4 heads

- 48” x 48” x 24ft

- table width 44”

G.A. Gray open side

- 3 heads

- 61” x 84” x 24ft

- table width 56”

Gidding & Lewis

- 4 heads

- ” x 39” x 30ft

- table width 32”

GRINDERS:

PRESSES:

LATHES:

MILLING:

EDM:

FORM GRINDING:

HONING:

INSPECTION EQUIPMENT:

RADIAL DRILLS:

DRILL PRESSES:

SAWS:

SHEARS:

IRON WORKER:

KEYSEATER:

COMPRESSORS:

WELDING:

GAS CUTTING:

MATERIAL HANDLING:

- 12 Bridge cranes 2 ton; 5 ton; 10 ton; 15 ton

- 8 Jib cranes 1 ton; 2 ton

- 4 Fork lift trucks 2 ton; 4 ton; 8 ton

SHOP WORKING AREA: 70,000 sq. ft

CEILING CLEARANCE: 16ft; 18ft; 21.5ft; 27ft

ENGINEERING:

- SolidWorks

- MasterCam software

- Cadkey

Authorized by the Association of Professional Engineering of Ontario to offer professional engineering services.

Machine – Fabricate

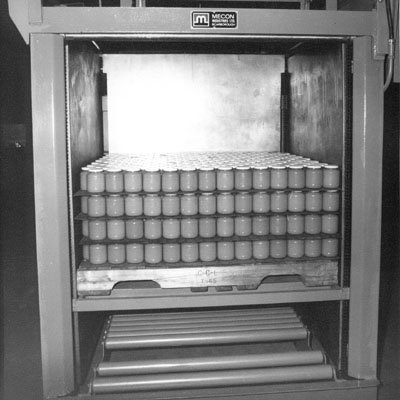

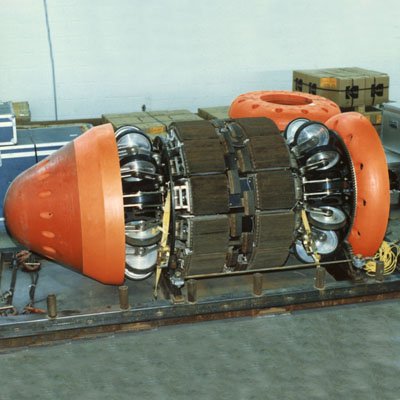

With over 50 years as a machine shop behind us, Mecon Industries Ltd has been producing precision machined parts and fabrications of the highest quality for automotive, industrial, marine, mining, medical and other commercial industries for a long time. Production or prototypes from large to small, short run or long run, we can do them all.

With over 50 years as a machine shop behind us, Mecon Industries Ltd has been producing precision machined parts and fabrications of the highest quality for automotive, industrial, marine, mining, medical and other commercial industries for a long time. Production or prototypes from large to small, short run or long run, we can do them all.

We guarantee unparalleled customer service, timely delivery and parts of the highest quality, call us.

We specialize in:

- CNC Milling

- CNC lathe machining

- General Machining

- Cylindrical grinding

- Welding

- Fabrication

- Prototyping

- Engineering

- Maintenance Repair & Overhaul

- Molds and Dies;

- “you design them, we make them”

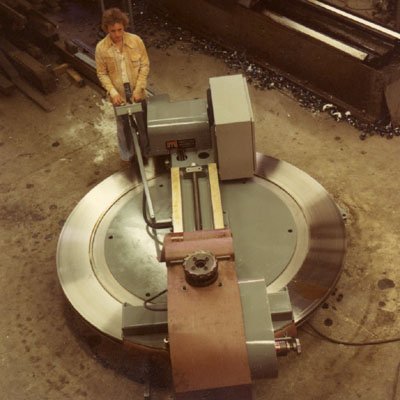

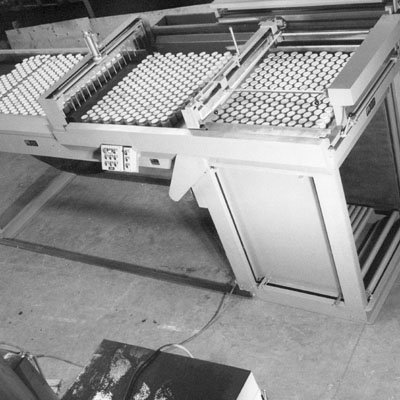

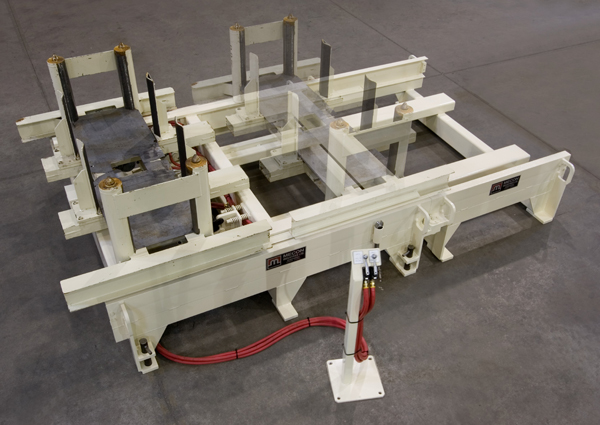

Mecon 400fs Feeder-Straightener

- Completely disassemble

- Steam cleaned

- New paint

- New Wiring

- New PLC controller

- Upgrade Drive(s)

- Improved performance and safety

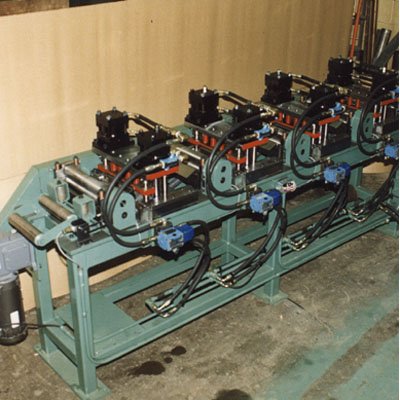

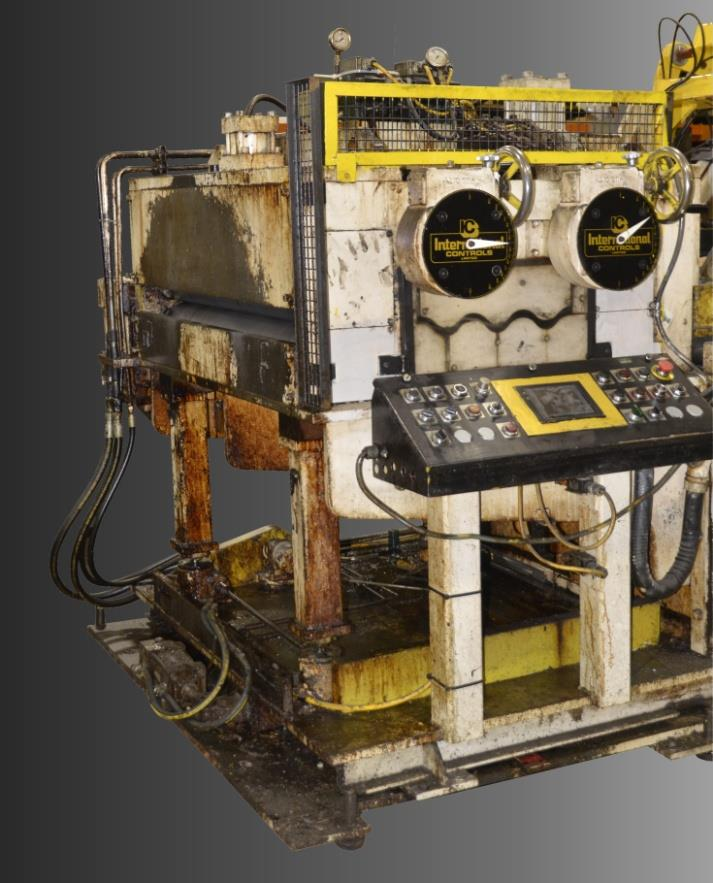

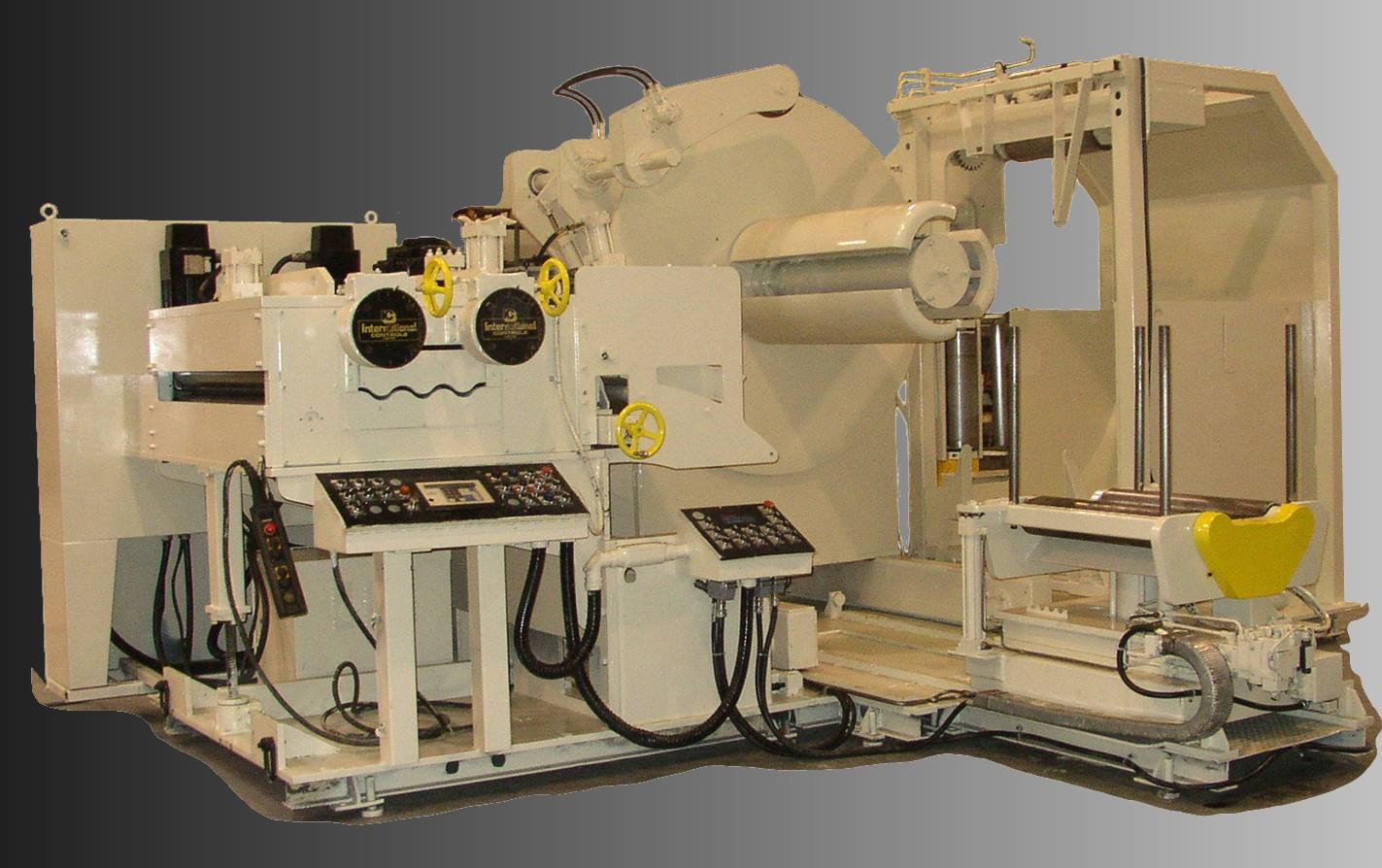

International Controls 20K x 48 Un-coiler Feeder/Straightener

- Completely disassembled

- Steam cleaned

- Painted

- Re-wired

- New PLC control system

- New drives

- New bearings

- Worn parts replaced

- Improved performance and safety

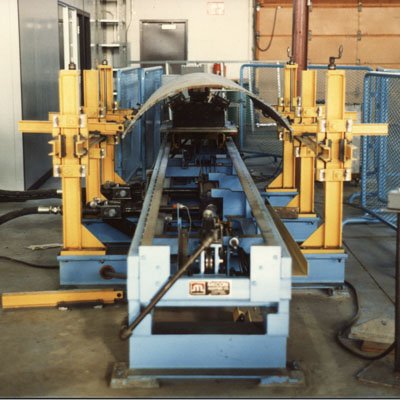

Design and Engineering

Since 1964, Mecon Industries has delivered professional engineering consulting, design and manufacturing services, developing innovative design solutions solving customer problems. With over 50 years of service, our engineering team has broad range of industry expertise to handle all aspects of your project.

From initial conception to a complete turnkey package, Mecon Industries can offer you a total solutions for your requirement. For companies seeking to improve their production methods, Mecon Industries offers proven expertise in finding cost effective solutions to manufacturing problems and automation needs.

We strive to give you the simplest, most reliable and safest design possible that can be manufactured at minimal cost and meets and exceeds your projects requirements.

Let us evaluate the requirements of your project for great solution at a competitive price.

Our Services

- Conceptual Design

- Engineering and Design Services

- Manufacturing Services

- Made-to-Order Machines

- Machinery Upgrades

- Rebuilding Machinery

- Special Purpose Machinery

- Material Handling Equipment

- Custom Machines

- We Specializes in

- Steel Coil handling systems

- Custom Machines

Authorized by the Association of Professional Engineering of Ontario to offer professional engineering services.