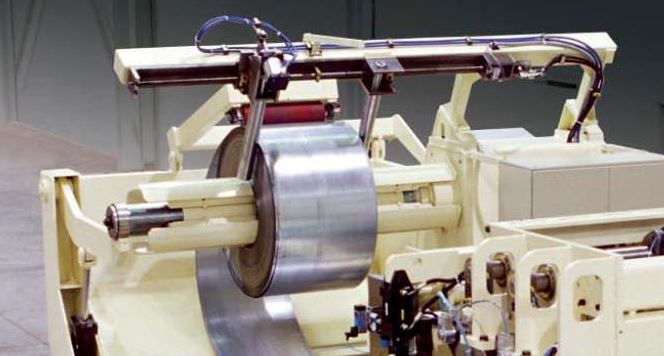

Material Guidance systems: ROLLER KEEPERS

- Roller Keepers are used to align the coil to process centerline

- Prevent coil telescoping during unwinding.

Coil Car with Narrow Coil Keeper Arms

- Typical power lift of 20″, 110” travel 1,000 to 60,000 lbs.

- Dual scissor stabilizer to support top of car when loaded off center

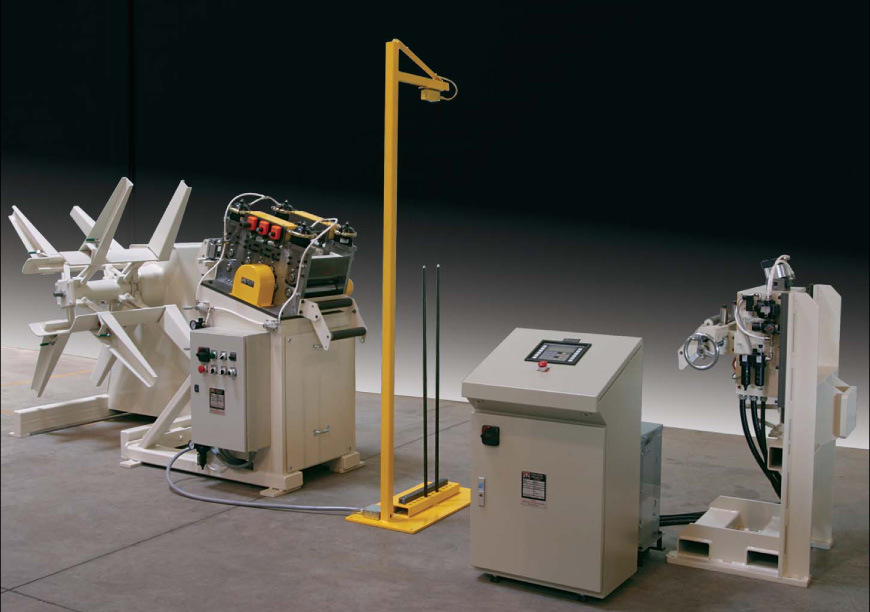

Mecon Laser Loop Control System:

- Controls the uncoiling process to supply material into an accumulation loop at a rate sufficient to meet or exceed the demands of the machine pulling material from the loop.

- Provides a simple method of setting the operating limits, the operating parameters, and the mode of the loop control.

- Allows the uncoiling process to run without abrupt changes in speed.

Multifunction pendant

- Multifunction pendant (replaces standard 2 button jog pendant)

- Mode select: Setup- Manual- Automatic, Reset, Feeder Auto start, Feeder Auto stop, Jog Reverse, Jog Forward

Material Guidance systems

- Screw adjust side side guides help hold the material square and centered as it enters the straightener.

- Screw adjust side guides are selfcentering, roll position is set by hand wheel.

Coil System Threading Table

- Eliminate the need for the operator to carry the start of the material from the coil to the straightener

- Safe material handling operation

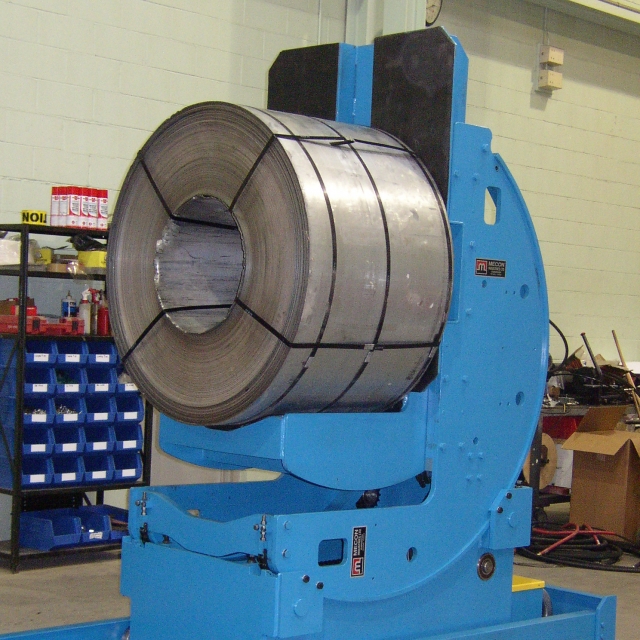

Coil Upender

- Easy and safe way to upend not only metal coils, but also molds, dies and other heavy and bulky loads.

- Available 1,000-60,000lbs standard, custom to you requirement.

Shear

- Modular construction to allow easy integration

- CRU-WEAR High chrome, high carbon tool steel shear blades with 4 cutting edges 1/2 x 3″.

- CYCLE TIME less than 1.5 sec.

Perimeter Safety Fencing

- 2.5″ sq. posts lagged to the floor.

- Spaces between are posts fitted with panels 1.5 x 1.5 angle frame and 10 ga. x 1 x 1 welded wire.

- Fixed panels are bolted in place. Any fixed panel may be removed by unbolting.

- Sliding or hinged doors may be placed anywhere in the perimeter/

- Telescoping doors and light curtains available

- Fully programmable multiple Safety Zones

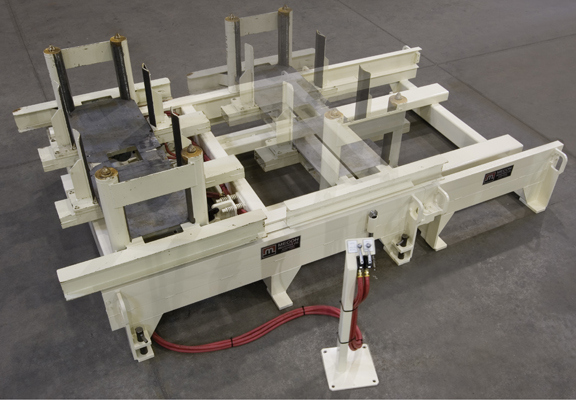

Stacking Pallets

- Adjustable posts to align blanks for stacking.

- Sub frame with cross tubes for lift truck forks and corner posts for stacking.

- Guide posts mounted on Tee Slotted bars for positioning

- Guide posts mounted on sliding and pivoting bases.

- Custom designed for your requirement.

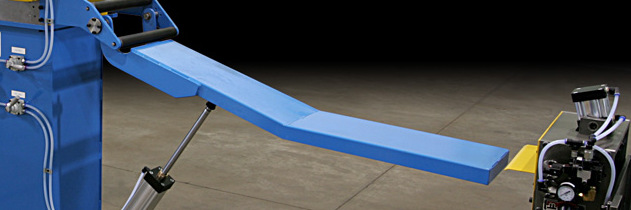

Die Feeder

- The tail out feeder mounts adjacent to the tooling and is used to deliver the end of the strip into the tooling.

- The feeder reduces the handling time and reduces waste. More of the tail is used to make parts, and the smaller tail is much easier to remove from the die.

- The feeder is mounted onto existing die or to the press bolster. Build to suit actual passline requirements.

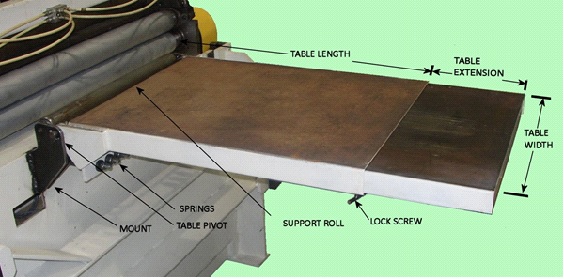

Feeder Exit Table

- This version has a solid top, spring suspension, and is extendable

- Options: mount for strip lubricator, roller top, nylon top, …

- Design to suit site requirements.

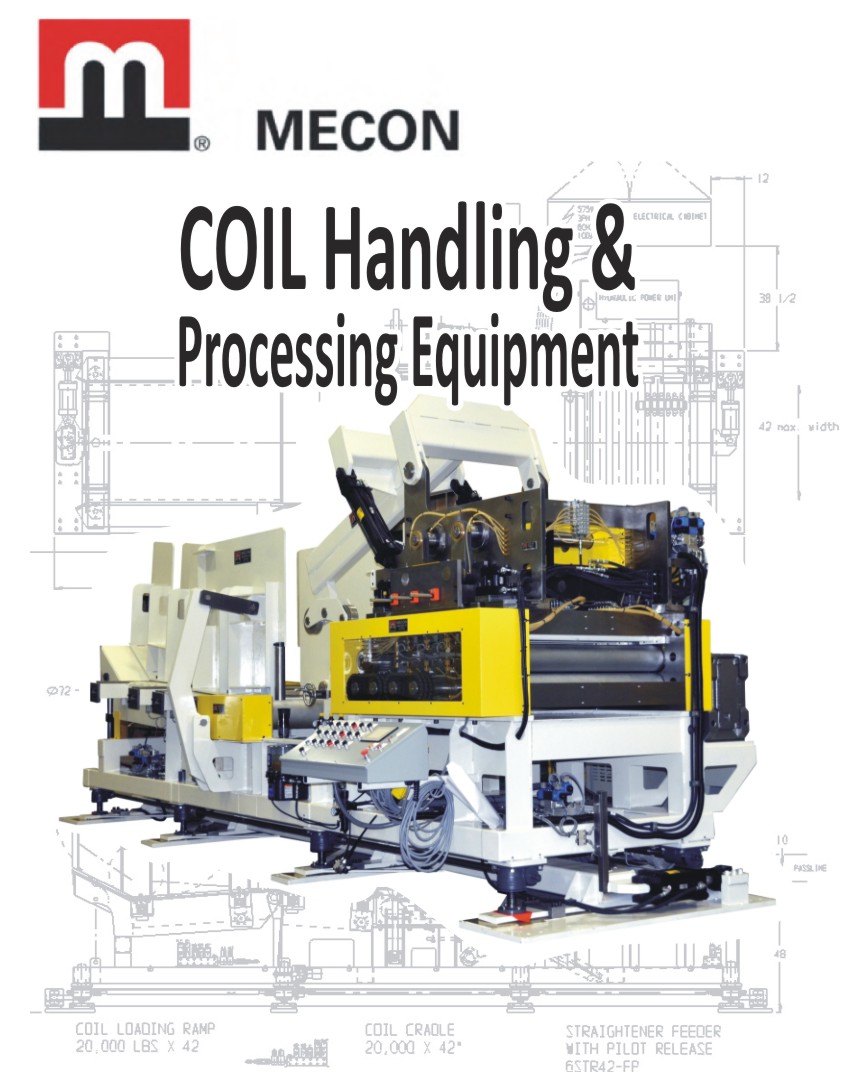

MECON HOME MECON COIL HANDLING MECON COIL HANDLING EQUIPMENT