Rebuild and Repair Services

Mecon Industries is a leading Canadian based manufacturer of both standard and custom equipment! Our company’s strength is in handling complete projects from initial design, to build, to operational testing. Our capabilities allowed us to take on jobs from many different industries. We also support our equipment or any other coil line equipment by providing preventive maintenance service and training. We also refurbish old equipment increasing performance and safety. Examples:

Typical refurbish to do list:

- Existing frame and cradle material, including threading sections, will be reused on rebuilt straightener including cradle gear box

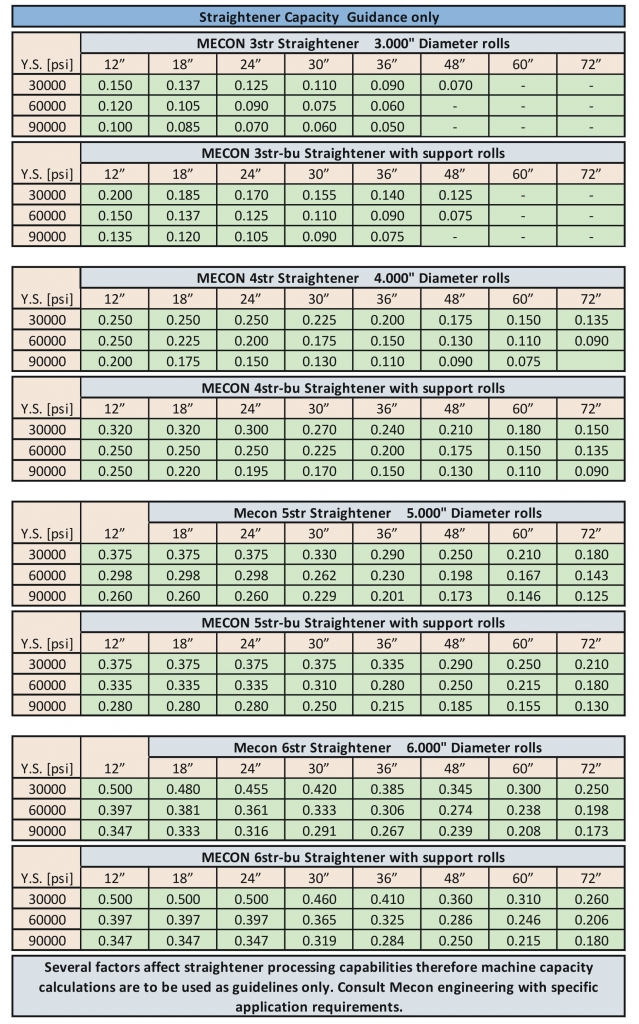

- Remove and Upgrade existing 4” straightener section with new complete 6” straightener having minimum operating capacities as outlined below

- Upgrade to new, operator screen and controls, all programing, gear boxes and servo drive systems as contained and necessary for the new 6” straightener including full pilot release option.

- Operator panel(s) disconnects etc. to be located in similar locations to present or made as a standalone pedestal(s) to ensure easy access to threading area and or out of high traffic locations

- Relocate hydraulics and valving from underneath the straightener to servo drive side

- Replace all hydraulic lines related to the straightener including electrical wiring and panels.

- Mecon to ensure proper communications between existing press controls and straightener

- Existing straightener will be stripped and repainted – colour to be determined

- Supply all necessary documentation, programs, operating manuals and spare/replacements parts lists

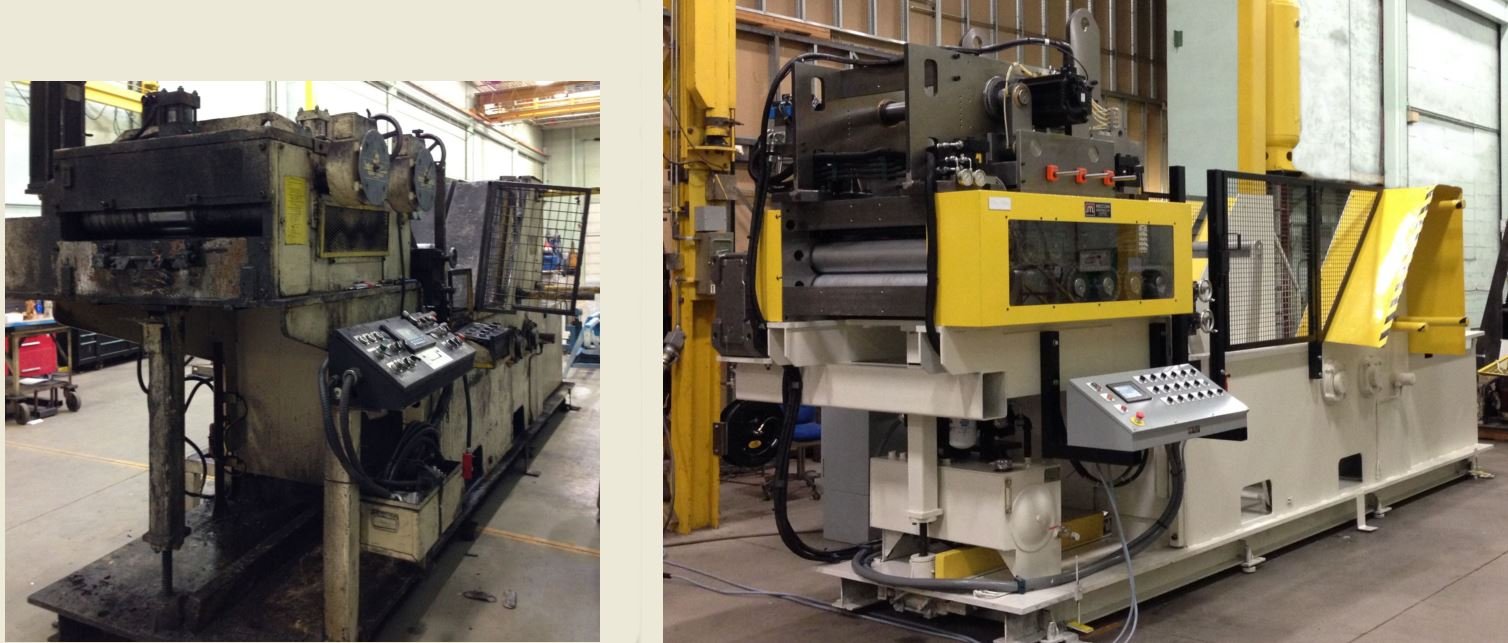

International Controls 20K x 36 Uncoiler Feeder/Straightener

International Controls 20K x 36 Uncoiler Feeder/Straightener

- Completely disassembled

- Steam cleaned

- Painted

- Re-wired

- New PLC control system

- New drives

- New bearings

- New hydraulics

- Worn parts replaced

- Improved performance and safety