Reels: Single and Dual Spindle

The reel is used in most uncoiling, recoiling applications. It can be fitted with a variety of drive and braking systems, combined with coil cars. pinch rolls, power straighteners, overarms, rolling mills or configured as a stand alone machine.

Reels are the best choice for thin, prefinished and other mark sensitive materials.

They support the coil on the inside diameter and thus avoid stock deformation problems.

- Suited to wide ranges of material

- Give precise control of the material

- Can unwind or rewind

- Available as single or dual spindle

- Quick coil change times using dual spindle versions

- Available with various drive and brake systems

- Prevents damage to soft, prefinished, and mark sensitive material

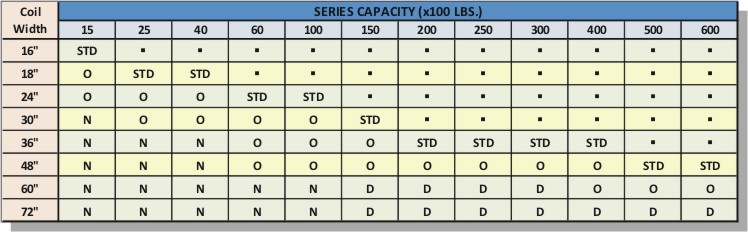

Uncoiler Capacity by Series

N = not available, O = optional, D=derate to next lower weight

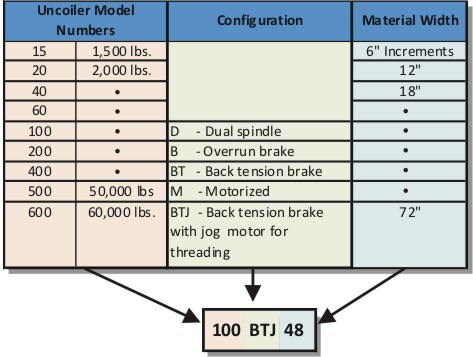

Uncoiler Part Numbering

Example: 10,000lbs. uncoiler with Back Tension brake with Jog motor 48″ wide

Typical uncoiler description: model 100btj24.

- Single spindle uncoiler, with threading / rewinding drive, and air brake.

- Hydraulic system is enclosed within the uncoiler cabinet.

- 4 segment mandrel with ramp style hydraulic expansion.

- Expansion pressure is monitored and system automatically maintains clamping pressure.

- Threading / rewinding drive consists of a hydraulic motor, and an air release / spring actuated clutch, connected to the spindle by a chain drive.

- Air brake acts to provide braking to prevent coil overrun. A multipressure air circuit provides low braking during pay out and high braking when stopped. Air pressures are set with regulators mounted at the uncoiler cabinet.

- Electrical components are wired back to control panel. Operator controls are mounted in control panel.

Machine cabinet fully encloses the drive and hydraulic system; components are easily accessed by removing the panel on the back of the cabinet. - Moveable inner and outer keeper arms allow the coil to be positioned anywhere on the mandrel for alignment to the process.

- The uncoiler has an air brake to maintain coil tension during processing. A hydraulic motor, and clutch for jogging coil. Jog speed 4 rpm.

- The mandrel is 4 segments, with wedge style expansion and is hydraulically expanded/retracted. Id range 19″ to 24.5″, O.D. max. 60″ with coil car (optional 72″max O.D.)

OPTIONS:

- Coil Widths: 24″ Std., 30″-48″ Opt.

- Light to heavy duty braking systems

- Hydraulic or mechanical mandrel expansion

- Side shift

- Coil clamping arms with idle or driven wheels

- Combination with coil car, or coil elevator

- Quick release coil keepers

- Laser loop controls

- Laser centerline

UNCOILER OPTIONS Call (416)-751-1901

- COIL OVERARM

-IDLE WHEEL

-IDLE WHEEL with COIL GUARD

-HD AIR CYL, DUAL WHEEL

-FULL WIDTH IDLE ROLLER

-POWER WHEEL - OVERRUN BRAKE

- BACK TENSION AIR BRAKE

- AIR BRAKE,CLUTCH,JOG MTR

- DC MOTORIZED 3/4hp TO 20hp

- MAXIMUM COIL WIDTH

- HEAVY DUTY BTJ BASE

- TALL CABINET FOR UNDER LOOP

- PEDESTAL ELECTRICAL PANEL

- LINKAGE STYLE MANDREL

- WEDGE STYLE MANDREL

- HYD. MANDREL EXPANSION

- MAX COIL OD 60″

- MAX COIL OD 72″

- OUTBOARD SPINDLE SUPPORT

- QUICK RELEASE OUTER KEEPERS

- FULL DIAMETER BACK PLATE

- COIL REAR GUARDS

- COIL SIDE GUARD

- DANCER ARM LOOP CONTROL

- NON-CONTACT LASER LOOP CONTROL

- LASER CENTERLINE INDICATOR

- UNDER PADDLE LOOP CONTROL

- HYDRAULIC SIDE SHIFT BASE-18″

- TRAVELLING UNCOILER FOR ELEVATOR

- ROLLER COIL KEEPERS