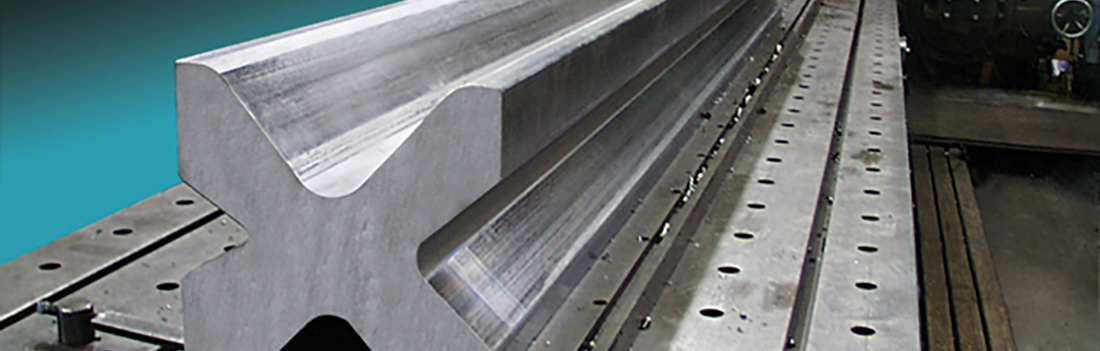

Mecon Industries is a press brake tooling manufacturer with wide product line of dies punches and accessories

Mecon Industries is a reliable supplier of press brake tooling for the North American market. We offer various dies and punches (standard, heavy duty, special, hemming, etc) along with die rails, punching plates, stops, etc for different production needs. Please check our How to Order Dies webpage and Press Brake Tooling manufacturer section for detailed specifications of tools and accessories we can provide. Can’t find what you need, send us a drawing of the part to be made and a custom tool will be designed.

Mecon Industries is a reliable supplier of press brake tooling for the North American market. We offer various dies and punches (standard, heavy duty, special, hemming, etc) along with die rails, punching plates, stops, etc for different production needs. Please check our How to Order Dies webpage and Press Brake Tooling manufacturer section for detailed specifications of tools and accessories we can provide. Can’t find what you need, send us a drawing of the part to be made and a custom tool will be designed.Years of expertise in Canada’s press brake tooling industry

Looking for a press brake tooling manufacturer in Canada and the US?

Mecon Industries is the right choice for you! Finding the supplier of press brake tooling in Canada and US is not an easy task with numerous distributors, resellers and others. Mecon Industries is a supplier and press brake tooling manufacturer at the same time which makes us perfect fit for procurement departments. Interested in our products? Check our online Press Brake Tooling quotation form to request quote or call us today at +1 (416) 751-1901 to find out more information about press brake tooling for.

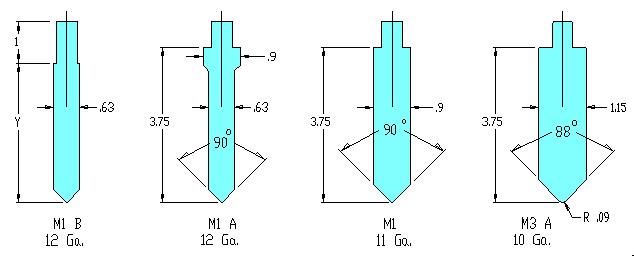

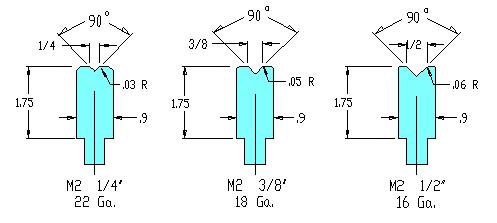

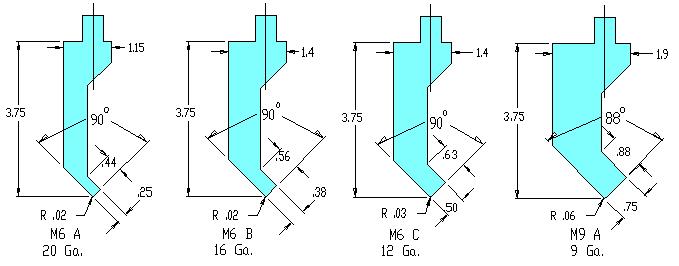

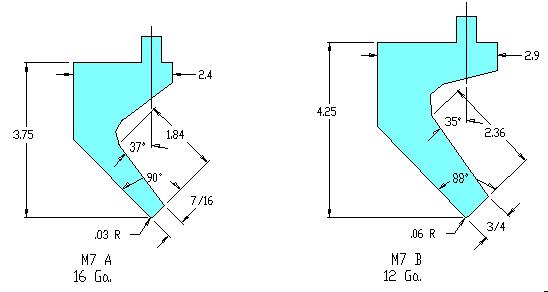

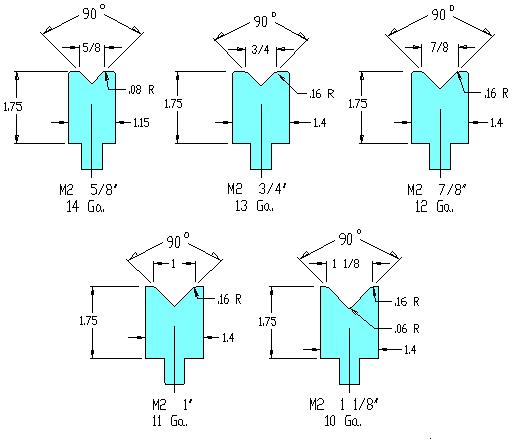

Light Gauge Right Angle Bends

Use 90° punch and die combinations with bottoming technique to produce close tolerance bends in light gauge material. For air bending technique (less than 90°) punch and die combinations supplied on request.

Note: Punch and die heights ± 1/8″

Punch M1B (12 Ga.) Punch M1A (12 Ga.) Punch M1 (11 Ga.) Punch M3A (10 Ga.)

Die M2 ¼” (22 Ga.) Die M2 3/8″ (18 Ga.) Die M2 ½” (16 Ga.)

Punch M6A (20 Ga.) Punch M6B (16 Ga.) Punch M6C (12 Ga.) Punch M9A (9 Ga.)

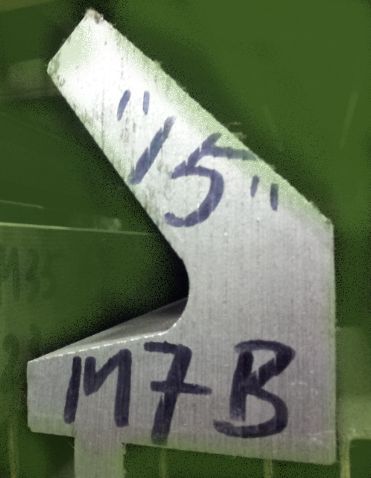

Punch M7A (16 Ga. Punch M7B (12 Ga.)

Die M2 5/8″ (14 Ga.) Die M2 ¾” (13 Ga. Die M2 7/8″ (12 Ga.)

Die M2 1″ (11 Ga.) Die M2 1-1/8″ (10 Ga.)

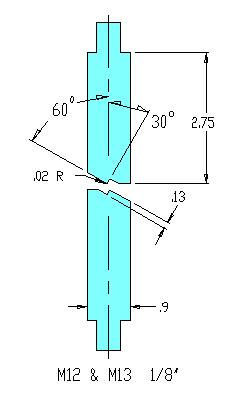

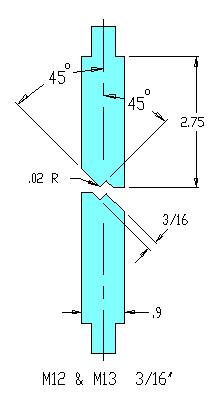

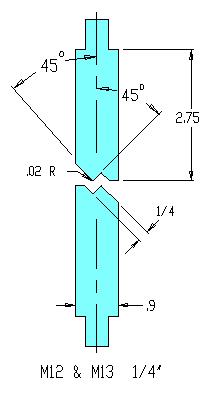

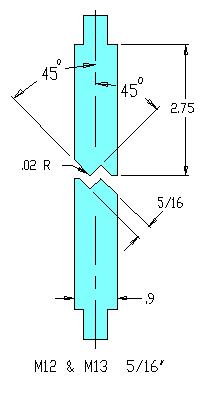

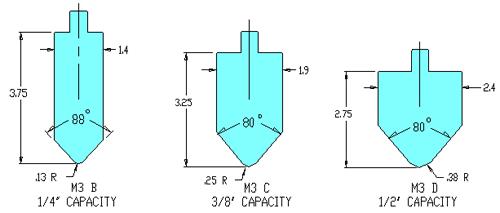

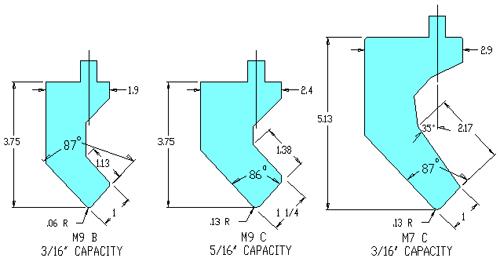

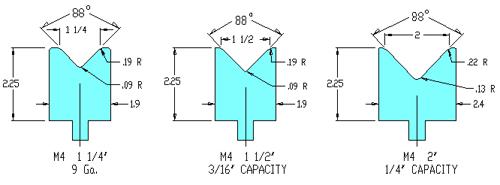

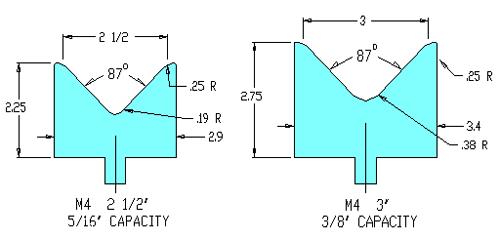

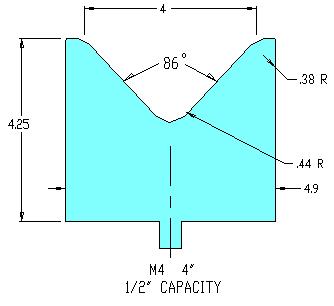

Heavy Duty Right Angle Bends

Use air bending technique with these dies to reduce tonnage required on heavy gauge material. Note: Punch and die heights ± 1/8″

Punch M3B (¼” Capacity), Punch M3C (3/8″ Capacity), Punch M3D (½” Capacity)

Punch M9B (3/16″ Capacity), Punch M9C (5/16″ Capacity), Punch M7C (3/16″ Capacity)

Die M4 1-¼” (9 Ga.), Die M4 1-½” (3/16″ Capacity), Die M4 2″ (¼” Capacity)

Die M4 2-½” (5/16″ Capacity), Die M4 3″ (3/8″ Capacity), Die M4 4″ (½” Capacity)

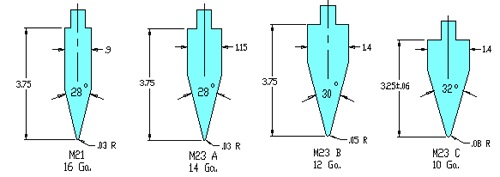

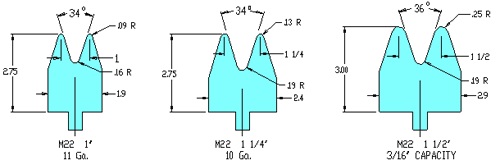

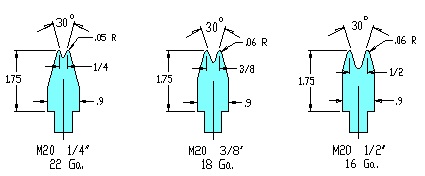

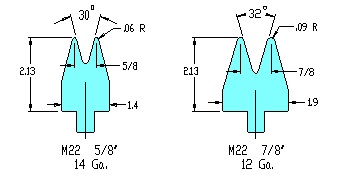

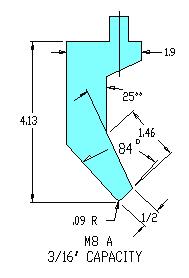

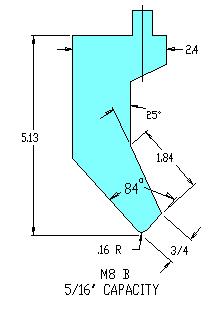

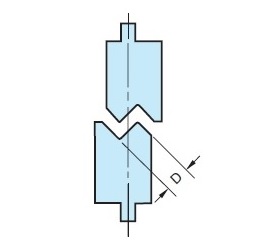

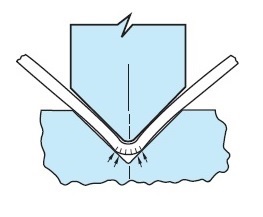

Acute Angle Bending Dies

Use these dies to produce preliminary bend for hemming operation or air bend angles less than 90°. Regulating the depth that the punch enters the die opening varies the degree of the obtained bend.

Note: Punch and die heights ± 1/8″

Punch M21 (16 Ga.) Punch M21A (14 Ga.) Punch M23B (12 Ga.) Punch M23C (10 Ga.)

Die M22 1″ (11 Ga.) Die M22 1-¼” (10 Ga.) Die M1 1-½” (3/16″ Capacity)

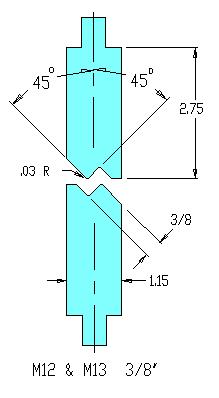

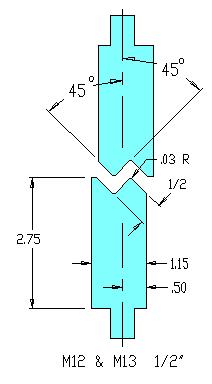

Die M20 ¼” (22 Ga.) Die M20 3/8″ (18 Ga.) Die M20 ½” (16 Ga.)

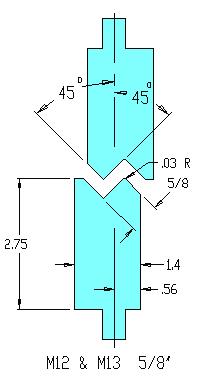

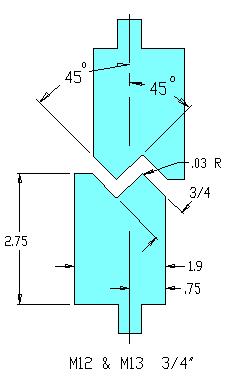

Die M22 5/8″ (14 Ga.) Die M22 7/8″ (12 Ga.)

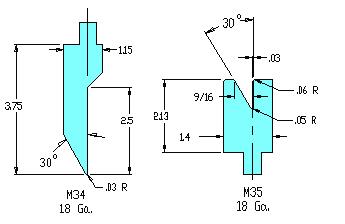

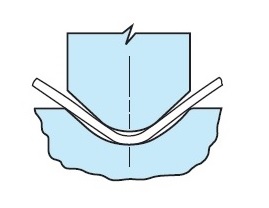

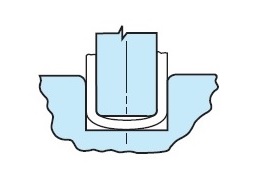

Hemming Die for Light Gauge Materials

Use Dies No. M34 and M35 to produce hem in two hits in same die with one handling.

Note: Punch and die heights ± 1/8″

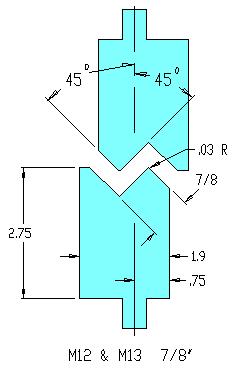

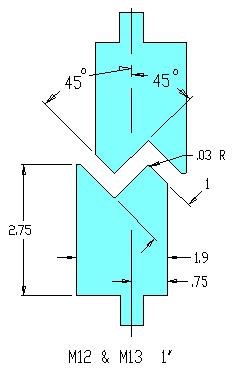

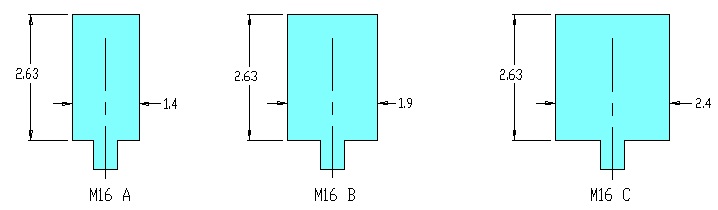

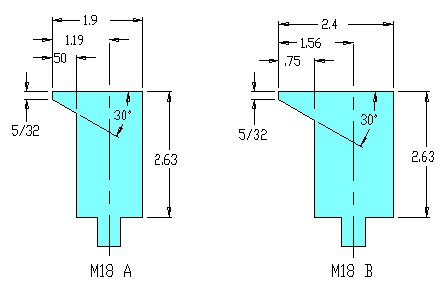

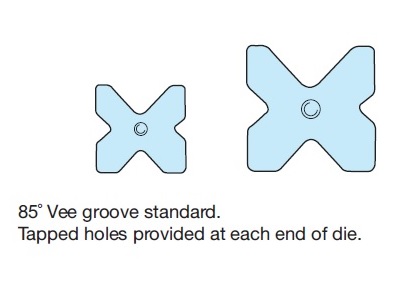

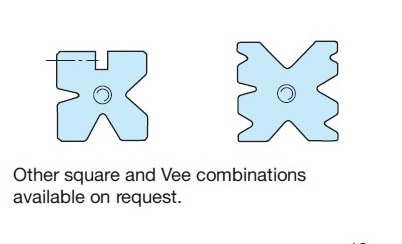

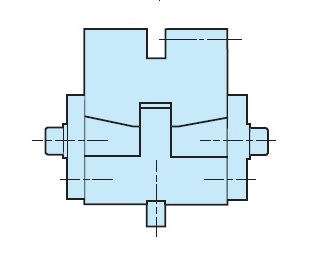

Heavy Duty Punches, 4-Way Dies

Note: Punch and die heights ± 1/8″

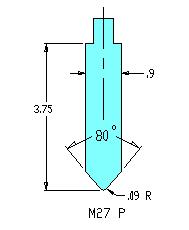

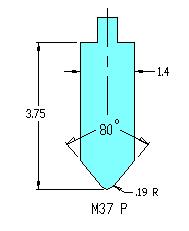

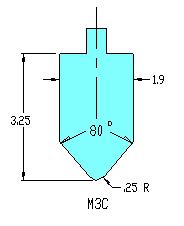

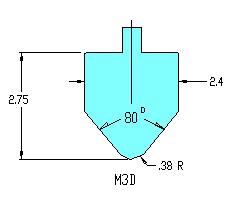

Heavy Duty Punches

4-Way Dies

| Square Size | 85° Vee Opening | |||

|---|---|---|---|---|

| 2.25" | 3/4 | 7/8 | 1-1/8 | 1-1/2 |

| 2.75" | 3/4 | 1 | 1-1/4 | 1-1/2 |

| 2.75" | 7/8 | 1-1/8 | 1-1/2 | 2 |

| 3.25" | 3/4 | 1 | 1-1/2 | 2 |

| 3.25" | 1 | 1-1/2 | 2 | 2-1/2 |

| 3.7" | 1 | 1-1/2 | 2 | 2-1/2 |

| 3.7" | 1-1/8 | 1-1/2 | 2 | 3 |

| 4.2" | 1 | 1-1/2 | 2 | 3 |

| 4.7 " | 1-1/2 | 2 | 2-1/2 | 3 |

| 5.2" | 1-1/2 | 2 | 3 | 4 |

| 5.7" | 1-1/2 | 2 | 3 | 4 |

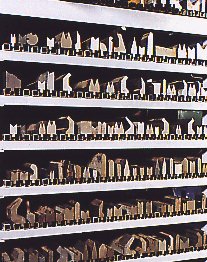

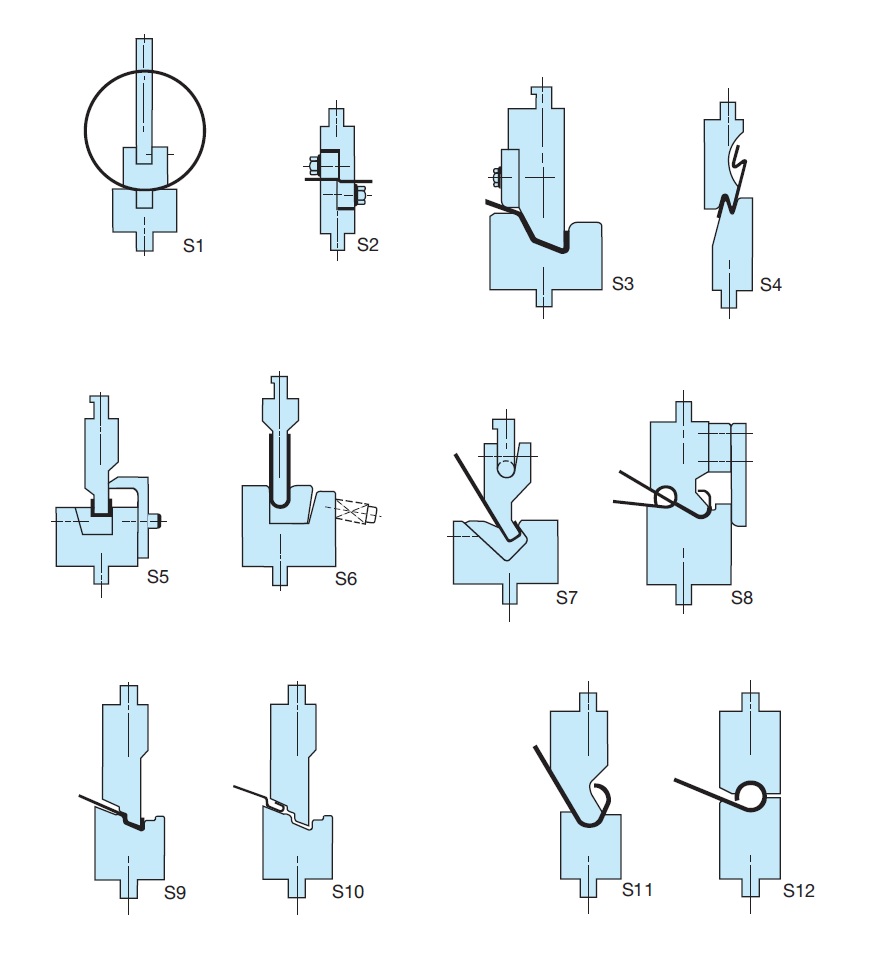

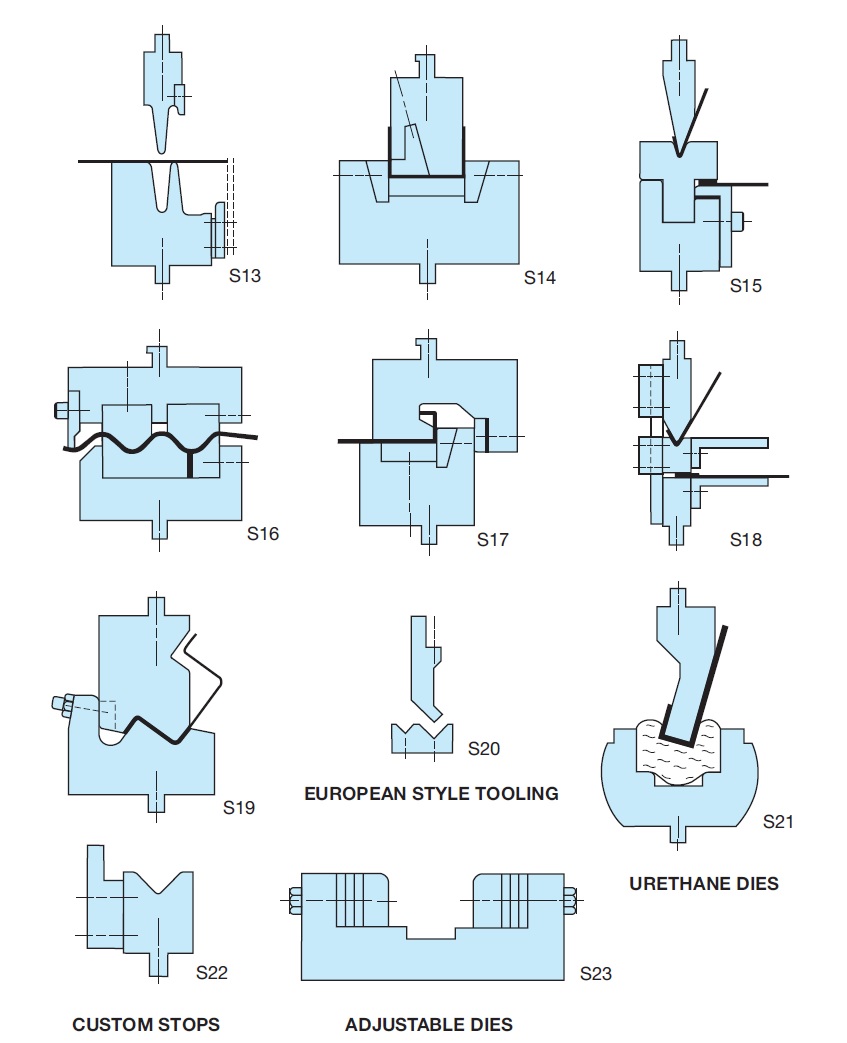

Samples of Special Tools

Brake Press Set-up Aids

| Standard Guage for Steel Sheets | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| GAUGE | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| THICKNESS | 0.239" | 0.224" | 0.209" | 0.194" | 0.179" | 1.164" | 0.149" | 0.135" | 0.105" | 0.075" | 0.06" | 0.048" | 0.036" | 0.03" | 0.024" |

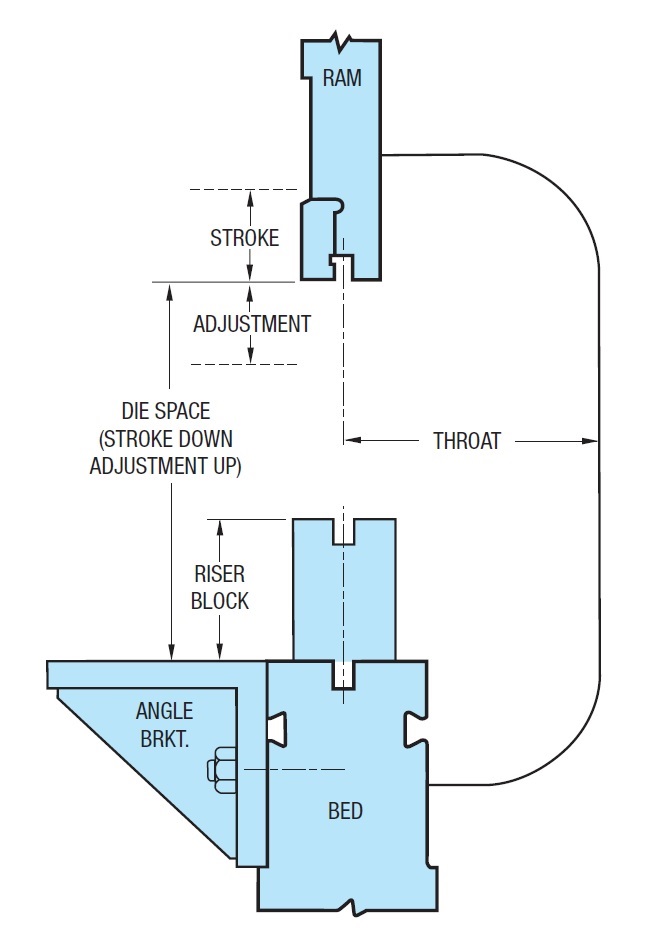

PressBrake Features

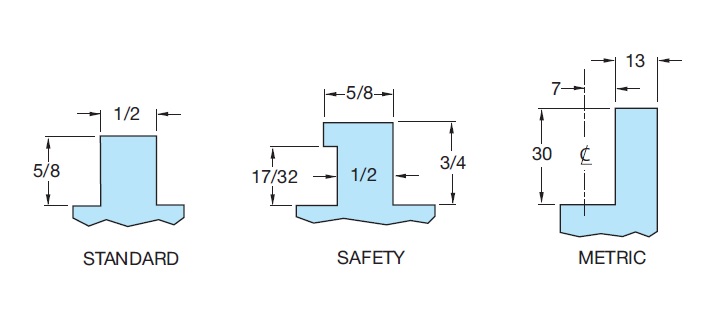

Common Types of Brake Punch Tongues – Others on Request

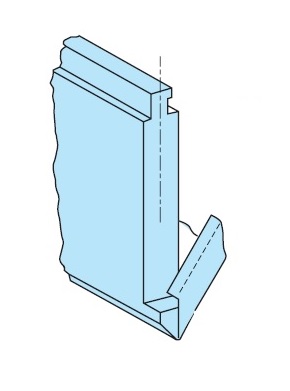

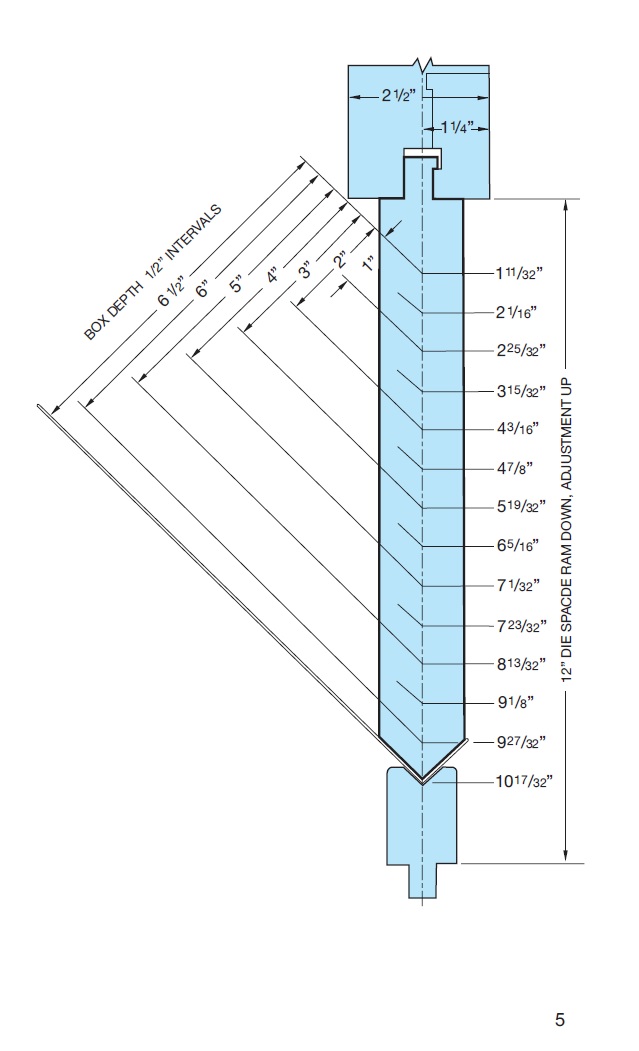

Box Forming

Brake Press Tonnage Chart

Tons Required Per Linear Foot to Bend Mild Steel Plate Having 60,000 PSI Tensile Strength

| Thickness of MATERIAL | Width of Die opening |

|||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gauge | Inches | 1/4" | 5/16" | 3/8" | 7/16" | 0.5 | 3/8” | 0.75 | 0.875 | 1 ” | 1.125 | 1.25 | 1.5 | 2" | 2.5 | 3" | 3.5 | 4" | 5" | 6" | 7" | 8" | 10" | 12" |

| 20 | 0.036 | 3.1 | 2.3 | 1.7 | 1.4 | 1.1 | ||||||||||||||||||

| 18 | 0.048 | 5.3 | 4 | 3 | 2.5 | 2.2 | 1.7 | 1.3 | ||||||||||||||||

| 16 | 0.06 | 9.6 | 7.1 | 5.6 | 4.5 | 3.8 | 2.8 | 2.2 | 1.8 | 1.5 | ||||||||||||||

| 14 | 0.075 | 11.9 | 9.2 | 7.6 | 6.3 | 4.7 | 3.5 | 3 | 2.5 | 2.1 | 1.8 | |||||||||||||

| 12 | 0.105 | 16.7 | 13.1 | 9.7 | 8 | 6.5 | 5.6 | 4.6 | 4.1 | 3.2 | ||||||||||||||

| 11 | 0.12 | 19.2 | 14.2 | 11.1 | 9 | 7.5 | 6.3 | 5.5 | 4.4 | 2.9 | ||||||||||||||

| 10 | 0.135 | 18.6 | 14.5 | 11.9 | 9.9 | 8.5 | 7.3 | 5.8 | 4 | |||||||||||||||

| 3/16" | 0.188 | 27.4 | 23.1 | 19.3 | 16.4 | 14.3 | 11.2 | 7.5 | 4.4 | |||||||||||||||

| 1/4" | 0.25 | 39.4 | 33.3 | 29.5 | 22.7 | 15.4 | 11.4 | 9 | 7.4 | 6.1 | ||||||||||||||

| 5/16" | 0.313 | 50.4 | 39.8 | 27 | 19.7 | 15.3 | 12.7 | 10.5 | 7.7 | |||||||||||||||

| 3/8" | 0.375 | 61.6 | 42.3 | 30.9 | 24 | 19.6 | 16.3 | 12.3 | 9.5 | |||||||||||||||

| 7/16" | 0.438 | 61.7 | 45.8 | 35.4 | 28.6 | 24.4 | 17.3 | 14.8 | 11.2 | |||||||||||||||

| 1/2" | 0.5 | 85.2 | 63.6 | 48.8 | 39.7 | 33.3 | 24.6 | 19.4 | 15.9 | 13.1 | ||||||||||||||

| 5/8" | 0.625 | 110 | 86.2 | 70 | 58.3 | 43.1 | 33.3 | 27.4 | 23.3 | 16.9 | ||||||||||||||

| 3/4" | 0.75 | 138 | 110 | 93 | 68.7 | 53.5 | 43.6 | 36.5 | 27.1 | 21 | ||||||||||||||

| 7/8" | 0.875 | 165 | 137 | 104 | 80.7 | 64.6 | 52.9 | 39.7 | 31.6 | |||||||||||||||

| 1" | 1 | 197 | 143 | 113 | 91.2 | 76.2 | 56.3 | 44.2 | ||||||||||||||||

| Notes: The tonnages indicated in bold italics are for die openings eight times the thickness of the metal. With an 8:1 die ratio, the inside radius of a right angle bend is approximately equal to the thickness of the material. |

||||||||||||||||||||||||

For other metals as compared to 60,000 PSI tensile strength mild steel adjust as follows:

- Soft brass: 50% of pressure listed.

- Soft aluminium: 50% of pressure listed.

- Stainless steel: 50% more than pressure listed.

- Chrome molybdenum: 100% more than pressure listed.

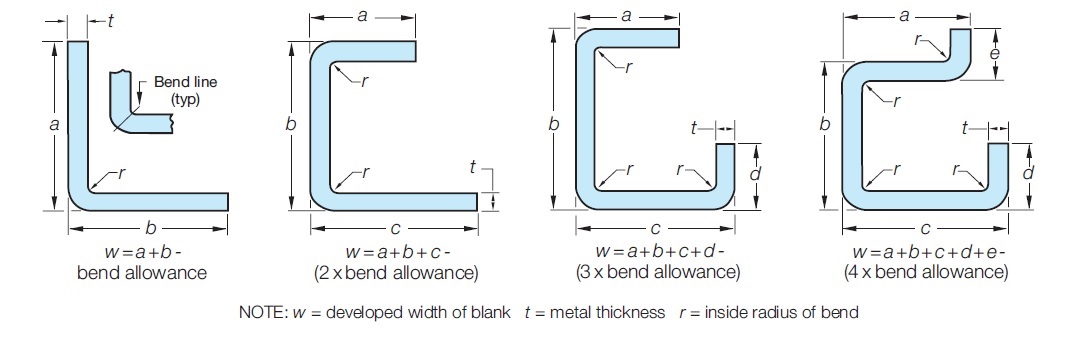

Brake Press Bending Allowance Chart

Bend Allowances for 90° Bends in Low‑Carbon Steel and Aluminum (Al)

| Bend Allowances for 90° Bends in Low-Carbon Steel and Aluminum | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bend allowance, inches, for bends with inside radius (r) of: | ||||||||||

| Metal thickness (t), in. | 1/32 in. | 1/16 in. | 3/32 in. | 1/8 in. | 1/4 in. | 1/2 in. | ||||

| Steel | Al | Steel | Al | Steel | Al | Steel | Al | (steel) | (steel) | |

| 0.032 | 0.059 | 0.057 | 0.066 | 0.068 | 0.079 | 0.082 | 0.093 | 0.095 | 0.146 | 0.254 |

| 0.05 | 0.087 | 0.078 | 0.101 | 0.091 | 0.114 | 0.105 | 0.129 | 0.118 | 0.168 | 0.276 |

| 0.062 | 0.105 | 0.095 | 0.118 | 0.108 | 0.132 | 0.12 | 0.145 | 0.133 | 0.183 | 0.29 |

| 0.078 | 0.128 | 0.116 | 0.142 | 0.131 | 0.155 | 0.144 | 0.169 | 0.157 | 0.202 | 0.31 |

| 0.09 | 0.146 | 0.13 | 0.16 | 0.144 | 0.173 | 0.157 | 0.187 | 0.17 | 0.217 | 0.324 |

| 0.125 | 0.198 | 0.175 | 0.211 | 0.189 | 0.224 | 0.203 | 0.243 | 0.216 | 0.26 | 0.367 |

| 0.188 | 0.289 | 0.302 | 0.217 | 0.316 | 0.283 | 0.329 | 0.297 | 0.383 | 0.443 | |

| 0.25 | 0.382 | 0.395 | 0.409 | 0.365 | 0.424 | 0.378 | 0.476 | 0.519 | ||

| 0.313 | 0.488 | 0.501 | 0.515 | 0.569 | 0.676 | |||||

| 0.375 | 0.593 | 0.607 | 0.661 | 0.768 | ||||||

| 0.437 | 0.699 | 0.752 | 0.86 | |||||||

| 0.5 | 0.845 | 0.952 | ||||||||

| Bend Allowances for 90° Bends in Low-Carbon Steel and Aluminum (Metric) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Bend Allowance (mm) for Bends with Inside Radius (r) of: | ||||||||||

| Metal Thickness ( t ), mm (Inches) | 0.8 mm(1/32") | 1.6 mm(1/16") | 2.4 mm(3/32") | 3.2 mm(1/8") | 6.4 mm(1/4") | 12.7 mm(1/2") | ||||

| Steel | Al | Steel | Al | Steel | Al | Steel | Al | Steel | Steel | |

| 0.8 (0.032") | 1.5 | 1.4 | 1.7 | 1.7 | 2 | 2.1 | 2.4 | 2.4 | 3.7 | 6.5 |

| 1.3 (0.050") | 2.2 | 2 | 2.6 | 2.3 | 2.9 | 2.7 | 3.3 | 3 | 4.3 | 7 |

| 1.6 (0.062") | 2.7 | 2.4 | 3 | 2.7 | 3.4 | 3 | 3.7 | 3.4 | 4.7 | 7.4 |

| 2.0 (0.078") | 3.3 | 2.9 | 3.6 | 3.3 | 3.9 | 3.7 | 4.3 | 4 | 5.1 | 7.9 |

| 2.3 (0.090") | 3.7 | 3.3 | 4.1 | 3.7 | 4.4 | 4 | 4.8 | 4.3 | 5.5 | 8.2 |

| 3.2 (0.125") | 5 | 4.4 | 5.4 | 4.8 | 5.7 | 5.2 | 6.2 | 5.5 | 6.6 | 9.3 |

| 4.8 (0.188") | 7.3 | 6.5 | 7.7 | 5.5 | 8 | 7.2 | 8.4 | 7.5 | 9.7 | 11.3 |

| 6.4 (0.250") | 9.7 | 8.6 | 10 | 8.9 | 10.4 | 9.3 | 10.8 | 9.6 | 12.1 | 13.2 |

| 8.0 (0.313") | 12 | – | 12.4 | – | 12.7 | – | 13.1 | – | 14.5 | 17.2 |

| 9.5 (0.375") | 14.4 | – | 14.7 | – | 15.1 | – | 15.4 | – | 16.8 | 19.5 |

| 11.1 (0.437") | 16.7 | – | 17.1 | – | 17.4 | – | 17.8 | – | 19.1 | 21.8 |

| 12.7 (0.500") | 19.1 | – | 19.4 | – | 19.7 | – | 20.1 | – | 21.5 | 24.2 |

Notes of Interest

Offset Dies

Tonnage requirements can be reduced by air bending rather than bottoming (compromising on accuracy), and also by using larger radii on the forming points.

Radius Dies

Fracturing

Channel Dies

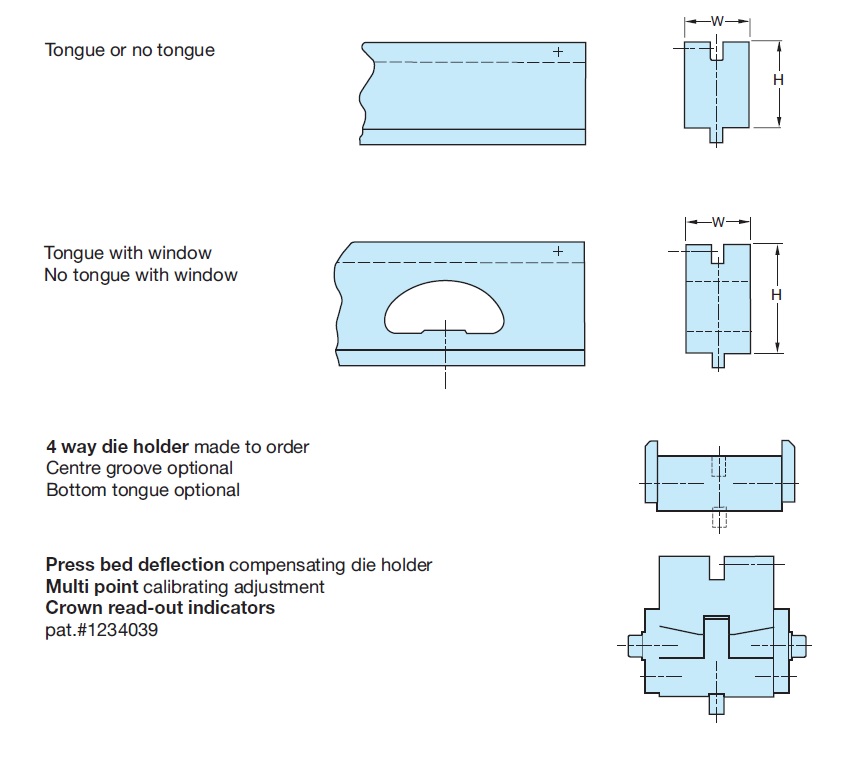

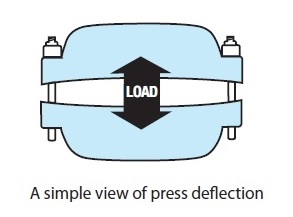

Press Brake Deflection

In some presses the bed and ram do not deflect in an even curve. The deflection can be mapped out for a press that is doing a particular job by taking accurate measurements along the length of test pieces. This deflection curve can then be reproduced by the machine.

- Shim the bottom (crowning) die manually by using a roll of adding machine paper. Start in the middle with a short piece, gradually increasing the length of the layers. The number of layers may be increased or decreased as required. Three layers of paper equals approximately 0.012-0.015 inches.

- If you are working within a small range of material thickness, the crown required may be reasonably consistent. Map out the deflection and machine it into the riser block.

- If you have dedicated tooling for a specific job, map out the deflection and have the tooling crowned.

- Purchase a “Mecon Deflection-Compensating Die Holder.”

Mecon Deflection-Compensating Die Holder.

- Multi point calibrating adjustment.

- Crown read-out indicators.

- Patent#1234039

Thinking Safety

Our dies are never intended to be used in equipment without a means provided to prevent hands or other body parts from entering or remaining in the die space at any time.

- Require that dies be set only by a qualified, safety-conscious die-setter.

- Insist that the die-setter be fully familiar with the press or machine’s manual.

- Provide all point-of-operation guards or devices necessary to avoid exposing any part of the operator’s body to the closing of the machine or press.

- Provide hand tools to insert, hold, and remove material, and to keep hands at a safe distance from the point of operation.

- Insist on safety practices and procedures and enforce them daily.

- Follow the instructions provided in the manual for the machine in which dies are being installed and operated.

- Ascertain that operators are trained in safety procedures, and arrange for periodic inspections to ensure that those procedures are being followed.

- Make available such safety-standard approved devices as pull-backs, fences, and infrared light curtain and controls for all press equipment. Two-button operation may also be necessary in some instances.