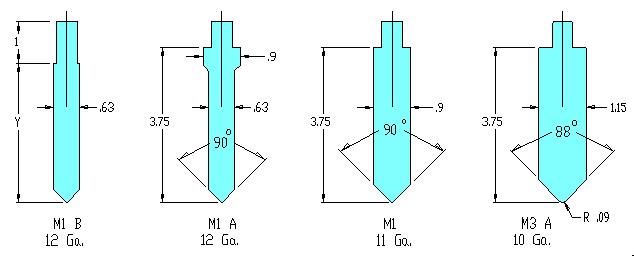

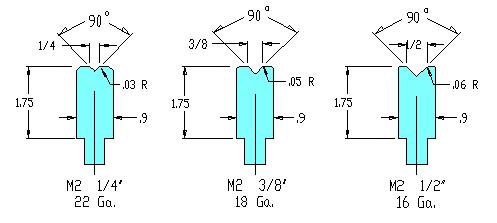

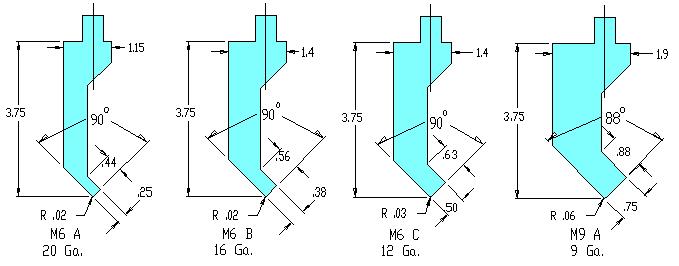

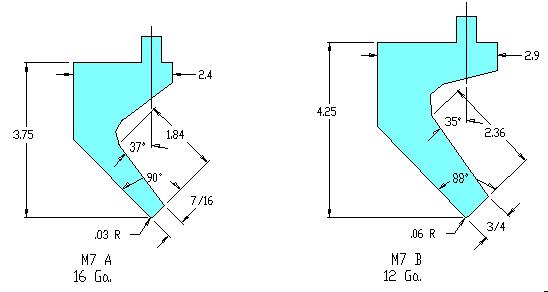

Light Gauge Right Angle Bends

Use 90° punch and die combinations with bottoming technique to produce close tolerance bends in light gauge material. For air bending technique (less than 90°) punch and die combinations supplied on request.

Note: Punch and die heights ± 1/8″

Punch M1B (12 Ga.), Punch M1A (12 Ga.), Punch M1 (11 Ga.), Punch M3A (10 Ga.)

Die M2 ¼” (22 Ga.), Die M2 3/8″ (18 Ga.), Die M2 ½” (16 Ga.)

Punch M6A (20 Ga.), Punch M6B (16 Ga.), Punch M6C (12 Ga.), Punch M9A (9 Ga.)

Punch M7A (16 Ga.), Punch M7B (12 Ga.)

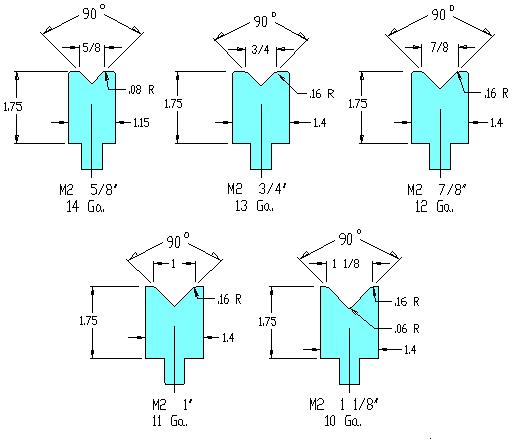

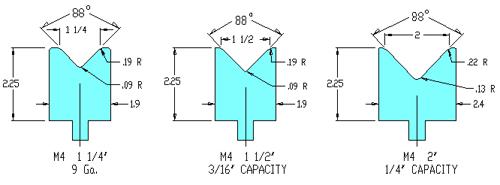

Die M2 5/8″ (14 Ga.), Die M2 ¾” (13 Ga.), Die M2 7/8″ (12 Ga.), Die M2 1″ (11 Ga.), Die M2 1-1/8″ (10 Ga.)

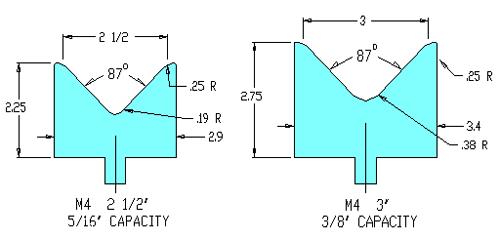

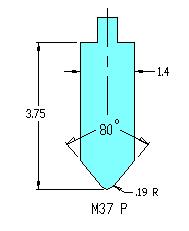

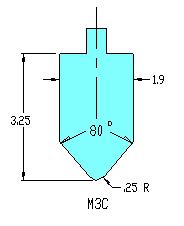

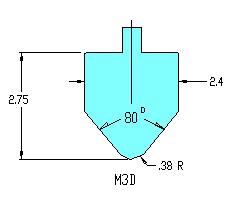

Heavy Duty Right Angle Bends

Use air bending technique with these dies to reduce tonnage required on heavy gauge material. Note: Punch and die heights ± 1/8″

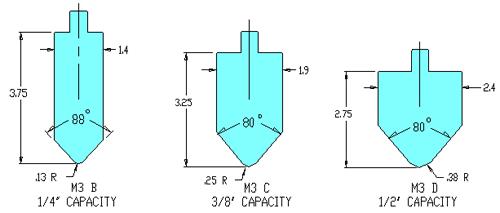

Punch M3B (¼” Capacity), Punch M3C (3/8″ Capacity), Punch M3D (½” Capacity)

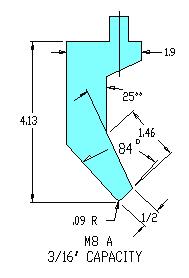

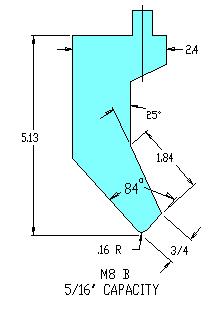

Punch M9B (3/16″ Capacity), Punch M9C (5/16″ Capacity), Punch M7C (3/16″ Capacity)

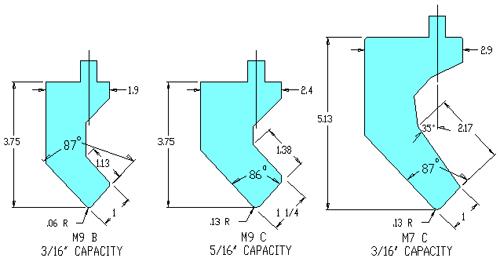

Die M4 1-¼” (9 Ga.), Die M4 1-½” (3/16″ Capacity), Die M4 2″ (¼” Capacity)

Die M4 2-½” (5/16″ Capacity), Die M4 3″ (3/8″ Capacity), Die M4 4″ (½” Capacity)

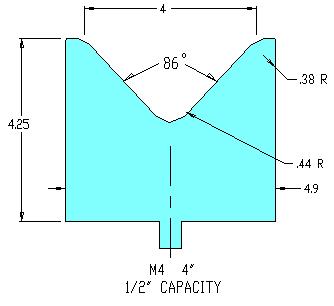

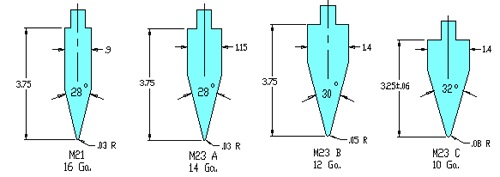

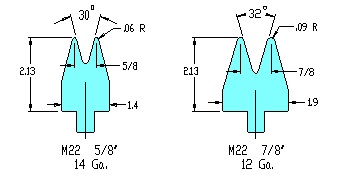

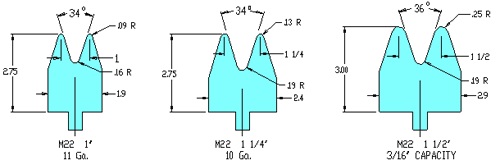

Acute Angle Bending Dies

Use these dies to produce preliminary bend for hemming operation or air bend angles less than 90°. Regulating the depth that the punch enters the die opening varies the degree of the obtained bend.

Note: Punch and die heights ± 1/8″

Punch M21 (16 Ga.), Punch M21A (14 Ga.), Punch M23B (12 Ga.), Punch M23C (10 Ga.)

Die M20 ¼” (22 Ga.), Die M20 3/8″ (18 Ga.), Die M20 ½” (16 Ga.), Die M22 5/8″ (14 Ga.), Die M22 7/8″ (12 Ga.)

Die M22 1″ (11 Ga.), Die M22 1-¼” (10 Ga.), Die M1 1-½” (3/16″ Capacity)

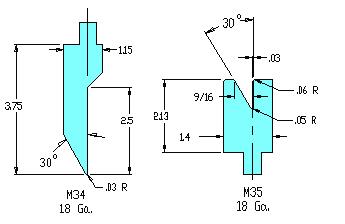

Hemming Die for Light Gauge Materials

Use Dies No. M34 and M35 to produce hem in two hits in same die with one handling.

Note: Punch and die heights ± 1/8″

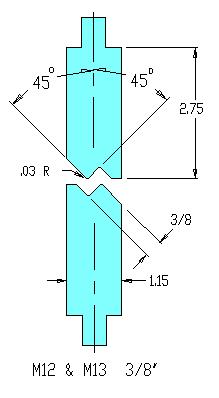

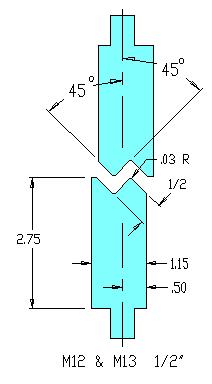

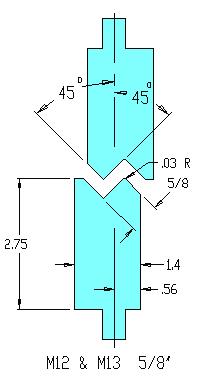

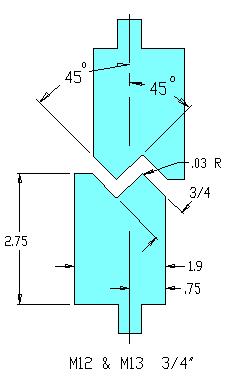

Right Angle “Offset” Die Combinations

Use these dies to produce close tolerance offset bends with reduced labour and handling time.

Tonnage requirements shown on bending chart are not valid for offset dies.

Note: Punch and die heights ± 1/8″

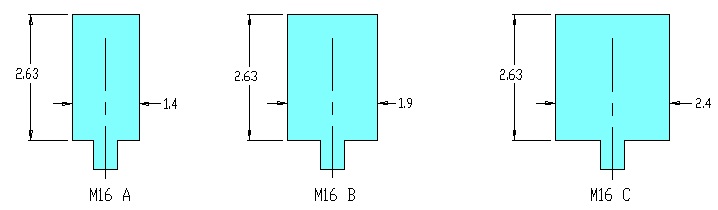

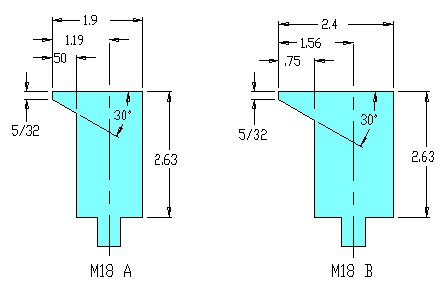

Flattening Die Combinations

Use these dies in pairs to produce hems or to close previously formed acute angle bends to the desired degree.

Note: Punch and die heights ± 1/8″

Group 1: M16A, M16B, M16C

Group 2: M18A, M18B

Punching Plates, Riser Blocks

Punching Plates

Striker Plate

“T” Slot Riser Plate

Riser Blocks

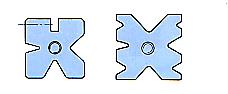

Tongue or No Tongue

Tongue with window.

Tongue with no window.

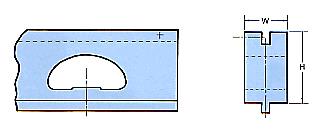

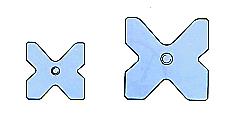

Square 4-Way Die Holder

Made to order.

Centre groove optional.

Bottom tongue optional.

Press Bed Deflection Compensating Die Holder

Multi-point calibrating adjustment.

Crown read-out indicators.

Patent # 1234039.

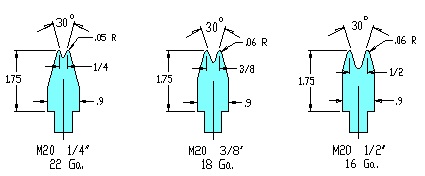

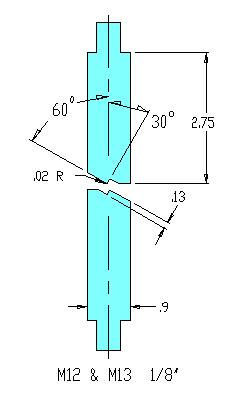

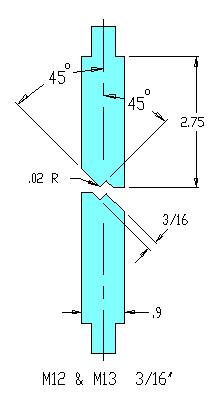

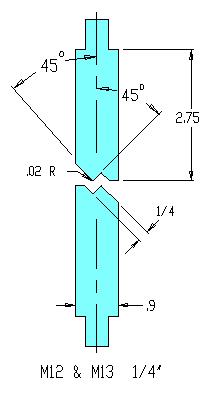

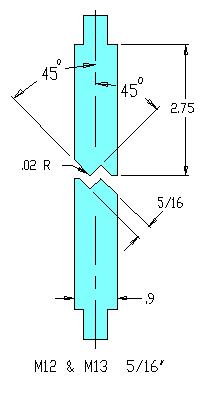

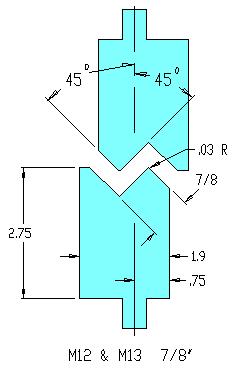

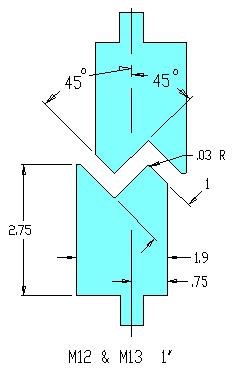

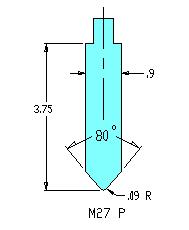

Heavy Duty Punches, 4-Way Dies

Note: Punch and die heights ± 1/8″

Heavy Duty Punches

4-Way Dies

85° Vee groove standard. Tapped holes provided at the end of each die.

Other square and Vee combinations available on request.

| Square Size | 85° Vee Opening | |||

|---|---|---|---|---|

| 2.25 | 3/4 | 7/8 | 1-1/8 | 1-1/2 |

| 2.75 | 3/4 | 1 | 1-1/4 | 1-1/2 |

| 2.75 | 7/8 | 1-1/8 | 1-1/2 | 2 |

| 3.25 | 3/4 | 1 | 1-1/2 | 2 |

| 3.25 | 1 | 1-1/2 | 2 | 2-1/2 |

| 3.7 | 1 | 1-1/2 | 2 | 2-1/2 |

| 3.7 | 1-1/8 | 1-1/2 | 2 | 3 |

| 4.2 | 1 | 1-1/2 | 2 | 3 |

| 4.7 | 1-1/2 | 2 | 2-1/2 | 3 |

| 5.2 | 1-1/2 | 2 | 3 | 4 |

| 5.7 | 1-1/2 | 2 | 3 | 4 |