Coil Handling System Configurations

Productivity

Selecting the proper options for your system will provide big paybacks in productivity gains.

- Eliminate waiting time for overhead cranes or lift trucks by installing coil cars and coil storage ramps Coils can be staged when convenient and are ready when the system needs them

- Reduce handling time and increase safety with coil clamping arms and threading equipment

- Use dual spindle uncoilers when feeding high demand systems like rolling mills or systems using partial coils

- Use sonar loop controls to smooth the uncoiling – straightening process, maintain proper loop geometry, and deliver more consistent material to the feeder

- Use a side shift base on the uncoiler to allow easy coil alignment and adapting for camber during processing

- Purchase the best material possible to ensure good quality, consistent parts

SUGGESTED SYSTEM ARRANGEMENTS

Mecon Industries Limited manufactures a variety of coil processing systems.

Many factors should be considered when determining the optimum arrangement.

• Plant space available

• Crane capacity

• Lift truck capacity

• Mark sensitivity

• Crane capacity

• Lift truck capacity

• Mark sensitivity

• Material thickness

• Material width

• Material strength

• Coil handling: – load and unload partial coils, or run full coils to end

• Material width

• Material strength

• Coil handling: – load and unload partial coils, or run full coils to end

• Coil weight

• Coil inside diameter

• Coil outside diameter

• Production required: -feed length, speed, feed angle, feed time

• Coil inside diameter

• Coil outside diameter

• Production required: -feed length, speed, feed angle, feed time

• Process type: – progressive stamping, blanking, blank and transfer, cut to length, pre-punch, etc.

• Budget

• Budget

Coil Lines

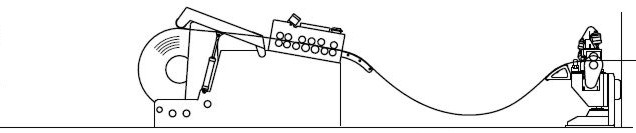

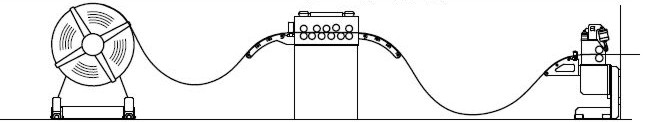

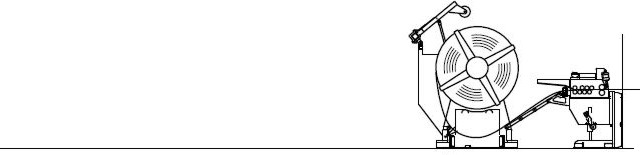

LINE 1

- BACK TENSION UNCOILER

- POWERED STRAIGHTENER

- PRESS-MOUNTED SERVO ROLL FEED

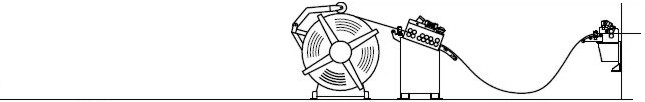

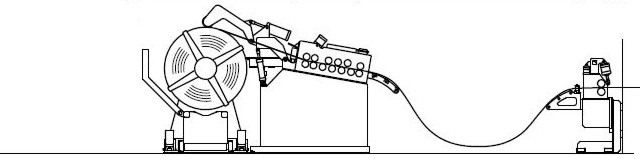

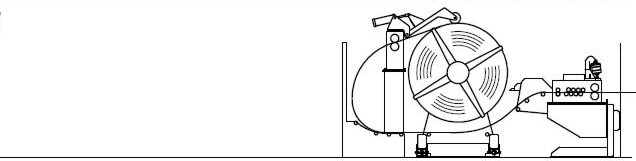

LINE 2

- MOTORIZED UNCOILER

- POWERED STRAIGHTENER

- SERVO ROLL FEEDER

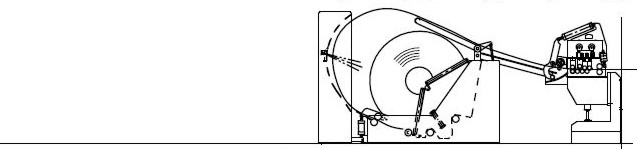

LINE 3

- POWERED TRAVEL & LIFT COIL CAR

- BACK TENSION UNCOILER (WITH JOG MOTOR)

- THREADING STAND

- POWERED STRAIGHTENER

- SERVO ROLL FEEDER

LINE 4

- MOTORIZED UNCOILER

- HOLD-DOWN ARM

- SERVO FEEDER-STRAIGHTENER

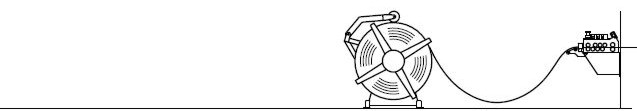

LINE 5

- MOTORIZED UNCOILER

- UNDER PADDLE LOOP CONTROL

- SERVO FEEDER-STRAIGHTENER

LINE 6

- POWERED TRAVEL & LIFT COIL CAR WITH IDLE ROLLS

- MOTORIZED UNCOILER WITH SONAR LOOP CONTROL

- OVERARM WITH COIL GUARD

- SERVO FEEDER-STRAIGHTENER (WITH THREADING OPTION)

LINE 7

- POWERED TRAVEL & LIFT COIL CAR WITH IDLE ROLLS

- BACK TENSION UNCOILER (WITH JOG MOTOR & SIDE SHIFT)

- PULL-OFF PINCH STAND WITH OVER-ARM

- COIL GUARD

- FEEDER-STRAIGHTENER

(WITH THREADING OPTION)

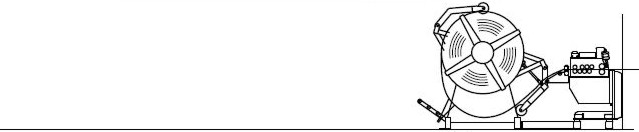

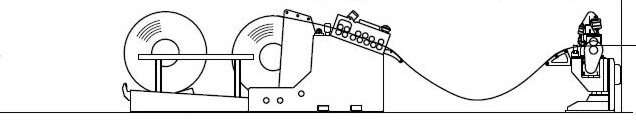

LINE 8

- COIL CRADLE

- COIL THREADING AND PREBENDER

- SERVO FEEDER STRAIGHTENER

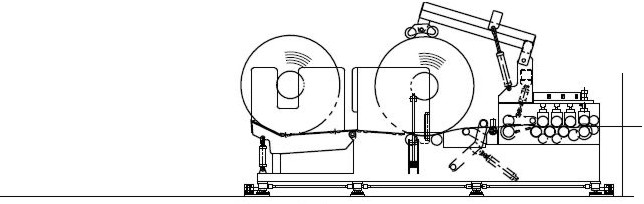

LINE 9

- COIL STORAGE RAMP

- COIL CRADLE STRAIGHTENER

- SERVO ROLL FEEDER

LINE 10

- COIL CRADLE STRAIGHTENER (WITH THREADING OPTION)

- FLOOR-MOUNTED SERVO ROLL FEED

LINE 11

- SERVODRIVEN COIL-CRADLE-STRAIGHTENER-FEEDER

- HEAVY DUTY DEKINKER AND COIL THREADER

- WITH COIL STAGING RAMP

- SIDE SHIFT BASE