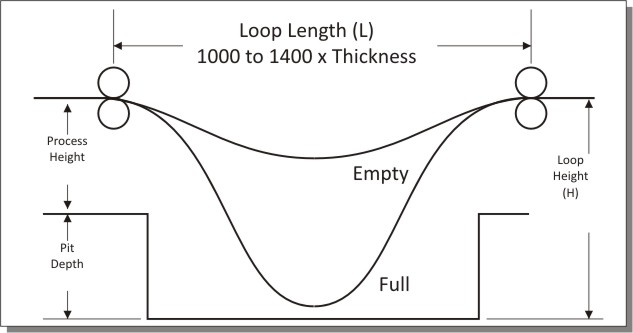

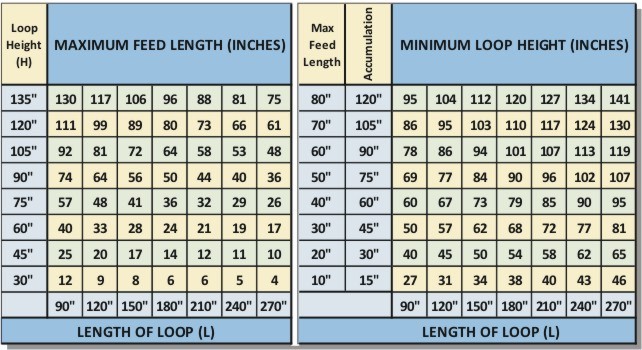

ACCUMULATION LOOPS and PITS

Most systems require an accumulation loop. The accumulation loop is used to allow the uncoiling process to payout at a nearly continuous rate while the feeding equipment stops and starts. Ideally the loop will accumulate at least 2 feed lengths of material. Thickness, material yield strength, and feed length are important factors to consider when determining loop geometry. The loop must store sufficient material to allow smooth operation. The material must not be curved smaller than the minimum bend radius to ensure that the proper loop shape is maintained and kinking does not occur: