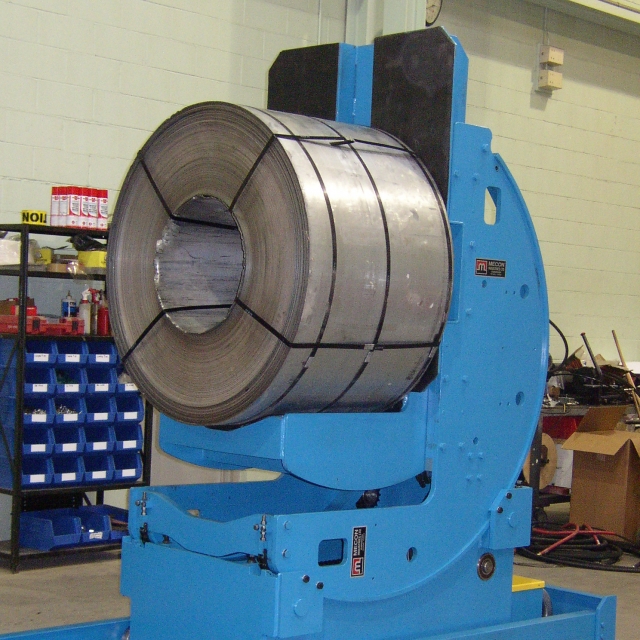

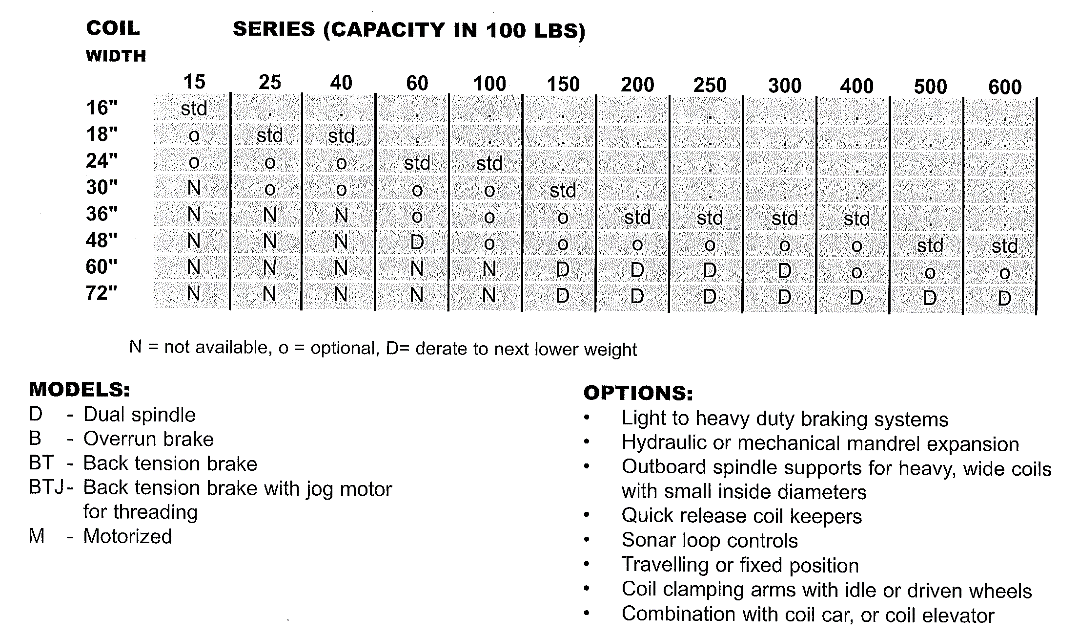

Uncoiler: Reels-Single and Dual spindle:

The coil reels used in most uncoiling and recoiling applications, primarily because they inherently avoid stock deformation problems. The stock is supported on the center core of the coil and is unreeled as required. May be fitted with a variety of drive and braking systems, combined with coil cars, pinch rolls, power straighteners, overarms, rolling mills or configured as stand alone systems. Reels are the best choice for thin, prefinished and other mark sensitive materials.

Advantages:

- Coil reel is suited to uncoiling a wide ranges of material

- Coil reel is easily able to maintain programmed tension downstream. Can be drag braked or powered unit

- Coil reel can be adapted to uncoil or recoil. Can easily rewind unused material

- Coil reel is less costly than cradles

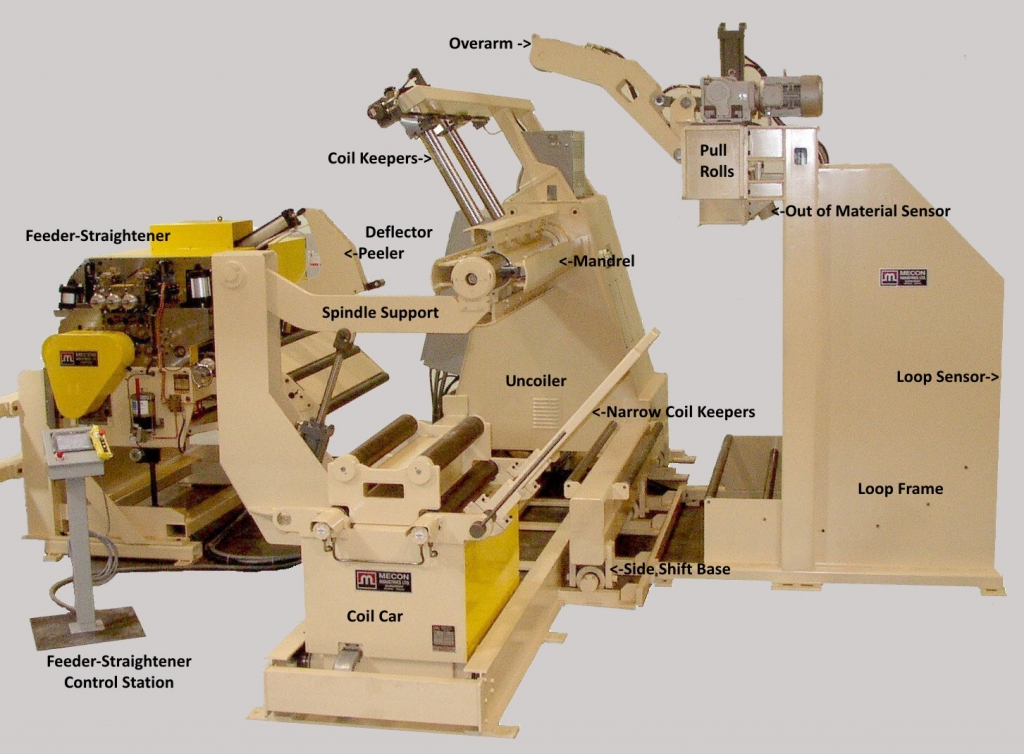

Coil Cradles

Easy, fast loading of coils is the single most important benefit offered by cradle-type uncoilers. They are often used in combination with straighteners for faster loading and adjustment, low power requirements and maintenance. Cradle-straighteners also save plant floor space.

Features:

- Rugged heavy duty steel construction

- Self centering coil keeper plates

- Lifting points for crane

- Forklift truck lifting tubes

- Driven cradle and straightening rolls

- All rolls hardened to 55RC

- All lubrication points marked and easily accessible

- Capacities from 0.060” to 0.375” mild steel, 12” to 72” (larger sizes call for quote)

- Standard payout speed of 0 to 80 fpm.

- Digital indicators show straightener roll position

- Standard straightener head with entry and exit pinch rolls and 7 straightening rolls. (( available for new high strength steels)

Advantages:

- Suited to process thick material.

- Easy and safe loading of coil.

- Accepts any range of coil I.D., and wider ranges of O.D.

- Confinement of coil helps in control of heavy materials.

- Straightener is easily built-in and synchronized with process speed.

- Suited to addition of threading systems for routing of heavy materials into feeds.

- Self contained, easy to relocate and setup

Cons:

- Rewind of unused material may be difficult

- Not recommended for use with thin, prefinished, or mark sensitive materials