Typical system requirements and proposed solutions:

Line 3: Coil Car Uncoiler Straightener Servo Feeder

Requirement: 30,000 lbs. x 48” wide coil feed system for steel

Maximum coil weight: 30,000 lbs.

Min/Max coil I.D.: 19 ½” -24 ½”

Max coil O.D.: 72”

Max coil width: 48”

Max stock thickness: (50KSI yield) .118” @ 42”

Max stock thickness: (90KSI yield) .078” @ 42”

Min stock thickness: .020”

Max progression: 24”

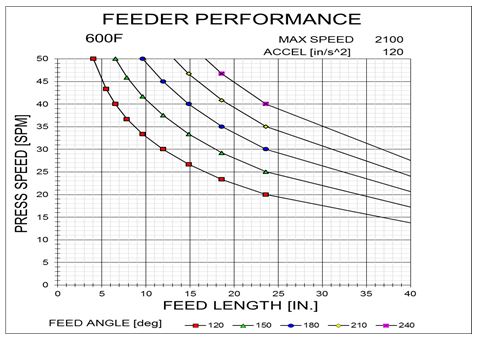

Max line speed: 47 SPM

System Configuration: Conventional Feed Line

Progression range: 0 to 999.99”

Min/Max line speed: 10-94 FPM

Power supply: 480 volt, 3PH, 60Hz

Air supply: 80 psi

Straightener with opening top to facilitate the cleaning of the rolls.

Proposed Solution:

Coil car model 300cc with powered top rolls.

- 30,000LBS capacity

- A coil car with power lift of 20″, 110” travel, hydraulic system common to uncoiler.

- Dual scissor stabilizer to support top of car when loaded off center.

Uncoiler model 300btj48 with optional side shift.

- Single spindle uncoiler, with threading / rewinding drive, and air brake.

- 4 segment mandrel with ramp style hydraulic expansion.

- Uncoiler side shift, 18″ of travel. The uncoiler is mounted on bronze bearings and is shifted sideways by a hydraulic cylinder for easy alignment of the coil to the process. Uncoiler may be shifted during processing or loading.

- The mandrel is 4 segments, with wedge style expansion and is hydraulically expanded/retracted. Id range 19″ to 24.5″, O.D. max. 60″ with coil car (optional 72″max O.D.)

Heavy Duty HD48 Threading – Coil over arm with power wheel. Peeler / coil breaker.

- The over arm clamps onto the coil to contain the coil end when the straps are cut.

- The wheel is powered by a hydraulic motor and drives the coil to thread the start of the coil to the input pinch rolls of the straightener.

- The coil breaker lifts to press the strip against a flattening block on over arm and thus de-kink the start of the strip. This allows easy threading of steel into straightener.

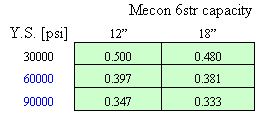

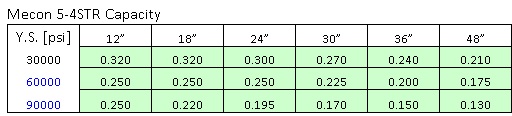

Powered Straightener model 5-4str48bu

- 11 hardened and ground rolls running on precision needle bearings,

- 2 entrance pinch rolls, 5.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading,

- 2 exit pinch rolls, 5.000″ diameter, open for threading, close for running,

- 7 straightening rolls, 4.000″ diameter, 4 lower rolls all driven, 3 upper rolls idle,

- Individual power adjust upper rolls, position shown on .001″ graduation counters.

- Straightener drive. Variable Frequency AC Motor control with AC induction motor.

- Speed 0-60 fpm. Infinitely variable.

- These drive systems give very smooth acceleration and deceleration with no sudden shocks to the material or drive components, and thus extend machine life and limit material marking.

- The drive system will be upgraded to 30 hp (to support the required feed/SPM requirement) to match the capacity of the straightener and the 30,000 lbs. coil. Material guidance

- Coil peeler and breaker guide material into straightener.

- Entrance vertical guide rolls to track the material.

- Exit ramp rolls support strip as it exits straightener and drops into loop.

Requirement:

Material: Steel 70,000 psi

Thickness: 3/8”

Width: 8”

Coil weight: 10,000 lbs

Process speed: 34 fpm

Feed length: 8”

Press speed: 50spm

Pass line height: 46″

System voltage: 575v, 3-phase, 60 Hz;

Proposed Solution:

COILCRADLE – STRAIGHTENER: 200CCS18

- 6str18 straightener upgrade

- motorized straightener adjustment screw

- adjust side guide rolls side plate rolls

- drive upgrade to 20 hp

- laser loop control

- extra heavy duty threading

- end pivot threading table

FEEDER: 600F18 with Antibackup brake

- Floor base- power pass line adjust

- Screw adjust sideguide with offset adjust

Requirement: Cut to length system

Material: 16-26GA steel

Coil Weight: 20,000lb coils

Width Material: 28 ½” to 54″

Cut lengths: 6 ¼ to 82 1/2”

Floor space: 55ft

Coil loading beside uncoiler

Important Considerations:

Tight tolerance on length.

Out of square causes problems

Flatness

Rewinding of partial coils

Coil Handling streamline and automate

Stacking system, even stacking very important

Minimize marking.

MECON Cut To Length Line with Conveyor Stacker system

Proposed Solution:

Coil car – 200cc with Coil keeper arms

- 20,000lbs capacity, 19″ vertical lift, 120″ travel

Uncoiler – 200m60

- 20,000lbs. capacity

- 60”, 4 segment mandrel with hydraulic expansion 18” to 22” diameter

- Overarm with idle wheel

- 100” travel base with tractor drive

- Overarm with idle wheel

- End Pivot, hydraulic lift threading table EPH 60 x 150

- The threading table is used to eliminate the need for the operator to carry the start of the material from the coil to the straightener .

- Extended entry conveyor with ramp .

- 2 sets side guide rolls with centering screw adjust .

- Coil centerline laser .

Combination Feeder Straightener – 4str60 .

- 11 hardened and ground rolls running on precision needle bearings,

- Bearings lubricated from centralized manifolds (hand lubricated)

- Entrance and exit pinch rolls; air actuated, lower rolls driven,

- 2 entrance pinch rolls, 4.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading,

- 2 exit pinch rolls, 4.000″ diameter, open for threading, close for running, servo drive with 575v to 440v transformer

- Flex system control HMI with I/O for shear control

- Exit side guide rolls with centering screw adjust

Shear – 08hs60

- MAXIMUM WIDTH 60″

- THICKNESS .080″ AT 60″ WIDE 60,000 UTS MILD STEEL

- THICKNESS 0.004″

- CYCLE TIME 2 seconds

Requirement: Uncoil 2 steel coils at the same time

Material: Steel 30,000 psi

Thickness: 20Ga

Width: 2″-15″

Coil weights: 1500 lbs

Process speed: 200 fpm

Press speed: 120spm

Proposed Solution:

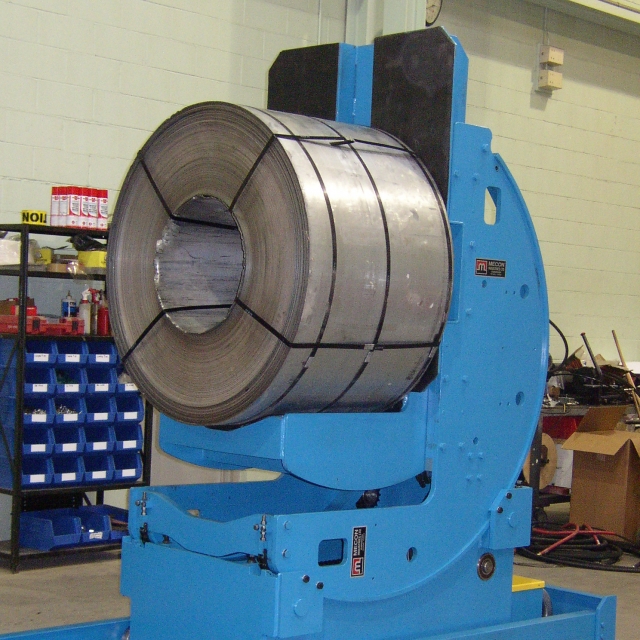

Dual UNCOILER model T15M16

- CAPACITY 1,500 lbs. per spindle

- MAXIMUM WIDTH 16″

- COIL ID. RANGE 12″ to 21″

- COIL MAXIMUM OD 60” typical

- dual spindle uncoiler,

- 3/4 hp DC spindle drive on each spindle

- Drives are controlled manually for jogging the coil, and automatically by the loop controlers during run.

MECON model T15M16 Tandem spindle uncoiler with 2 complete 15M uncoiler spindles