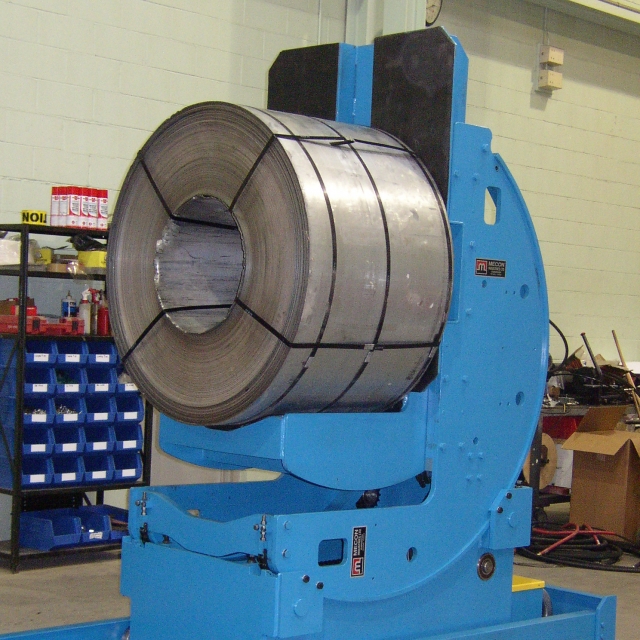

Coil Cradles

Easy, fast loading of coils is the single most important benefit offered by cradle-type uncoilers. They are often used in combination with straighteners for faster loading and adjustment, low power requirements and maintenance. Cradle-straighteners also save plant floor space.

Features:

- Rugged heavy duty steel construction

- Self centering coil keeper plates

- Lifting points for crane

- Forklift truck lifting tubes

- Driven cradle and straightening rolls

- All rolls hardened to 55RC

- All lubrication points marked and easily accessible

- Capacities from 0.060” to 0.375” mild steel, 12” to 72” (larger sizes call for quote)

- Standard payout speed of 0 to 80 fpm.

- Digital indicators show straightener roll position

- Standard straightener head with entry and exit pinch rolls and 7 straightening rolls. (( available for new high strength steels)

Advantages:

- Suited to process thick material.

- Easy and safe loading of coil.

- Accepts any range of coil I.D., and wider ranges of O.D.

- Confinement of coil helps in control of heavy materials.

- Straightener is easily built-in and synchronized with process speed.

- Suited to addition of threading systems for routing of heavy materials into feeds.

- Self contained, easy to relocate and setup

Cons:

- Rewind of unused material may be difficult

- Not recommended for use with thin, prefinished, or mark sensitive materials