Mecon Industries is a leading coil handling equipment manufacturer in Canada!

How Mecon became a successful coil handling equipment manufacturer?

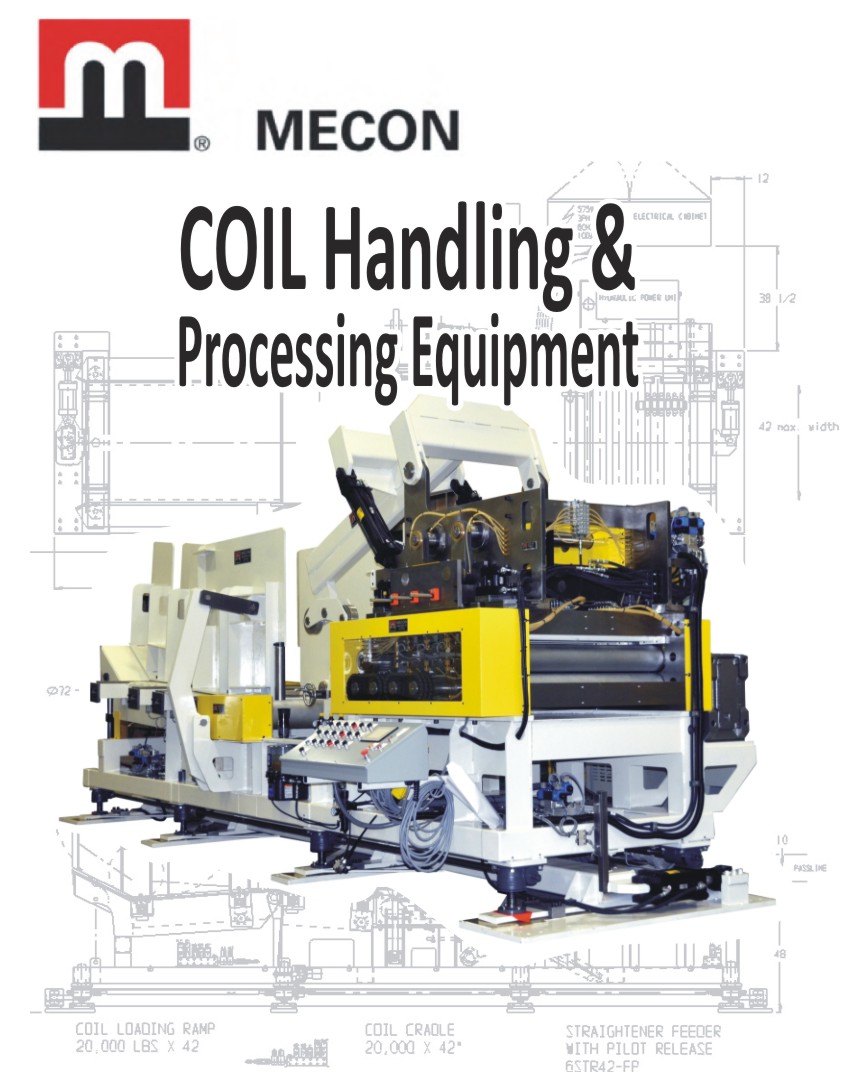

The answer is simple: Mecon Industries design, engineer, and build coil handling equipment for its Canadian, US and international clients in its large facility under one roof. This in-house approach allows them to control and manage all aspects of the design and production from start to finish. Mecon Industries stages its coil handling equipment in its Toronto’s production facility before shipping to insure that it functions as required. This allows Mecon to tune and make adjustments requested by the end user, you the customer, in a controlled environment rather than later in the field. We use coils supplied by the customer to guarantee correct operation when installed, the testing was done with your production material.

Consolidating design, engineering, production and testing at one location makes Mecon Industries an outstanding equipment manufacturer. Our clients receive fully operational coil processing lines, ready to serve their purpose. We take pride in offering solid engineering designs, precision workmanship with guaranteed quality, durability, reliability, and cost effectiveness.

What are the costs of coil handling equipment in Canada?

Mecon Industries is a very cost effective coil handling equipment manufacturer. We have tools that will guide you through the main parameters needed for estimating costs involved. Our online form for coil handling equipment quotations can assist in identifying major factors affecting coil handling equipment choices. Mecon’s online product catalog of coil handling and processing equipment showcases our product line with detailed technical descriptions, performance data and other useful information.Mecon Industries is truly at the forefront of coil processing progress as one of Canada’s top coil handling equipment manufacturers. Our engineers and designers are constantly looking for new ideas to improve our products. Mecon builds the most advanced coil handling equipment in our Toronto’s headquarters and supplies it to many Canadian, US and international customers. Our production facilities are equipped with the latest technology and are backed up by a team of highly skilled and experienced staff who have been in the coil handling equipment industry for years.

In-House Manufacturing

Designing coil handling equipment with Solidworks

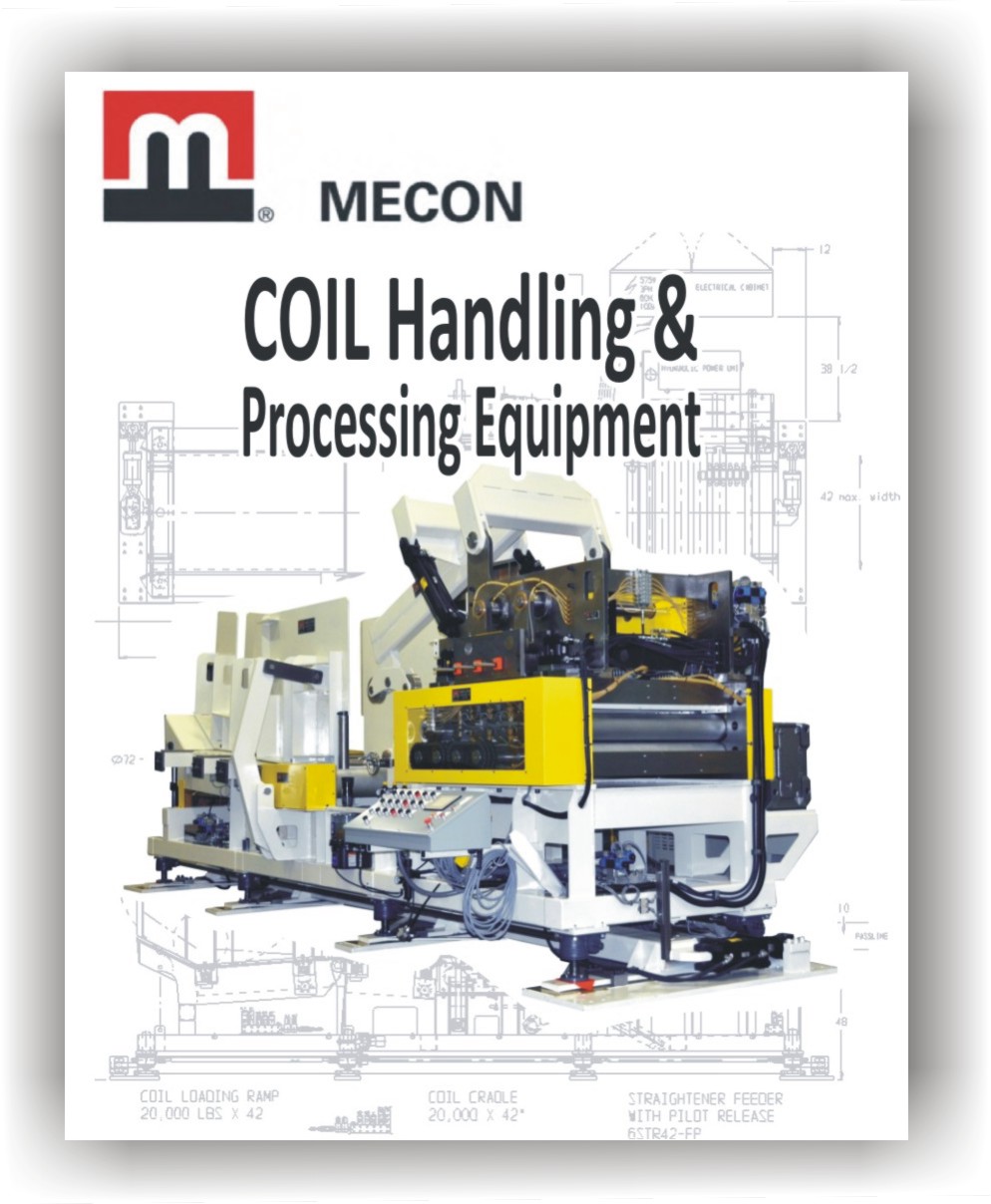

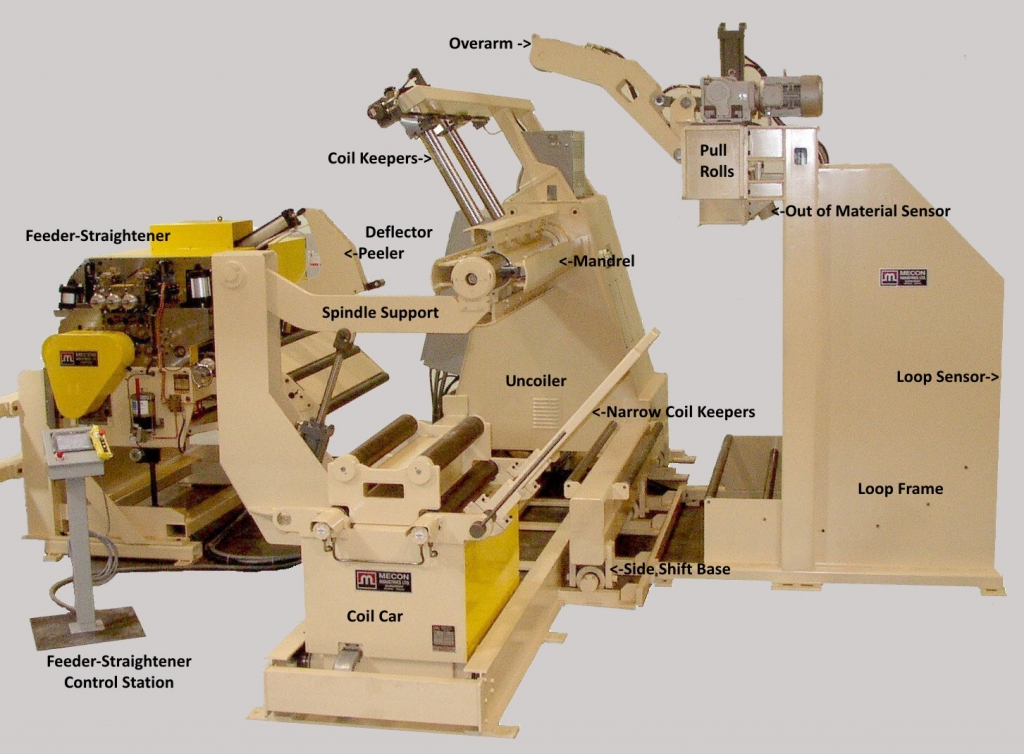

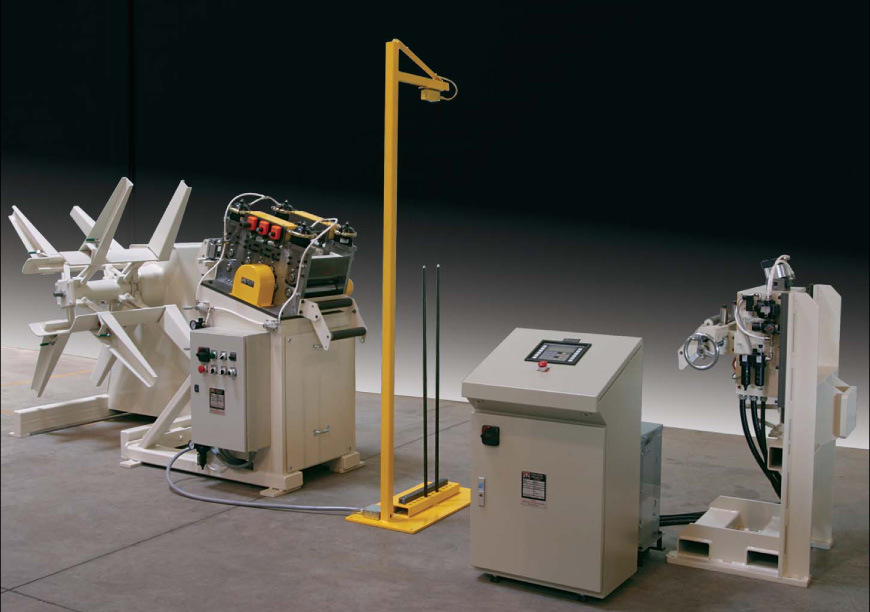

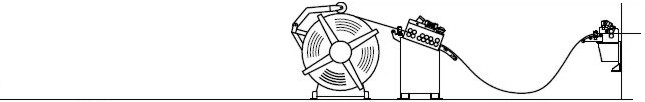

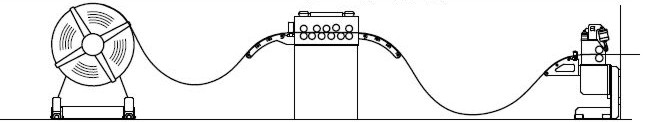

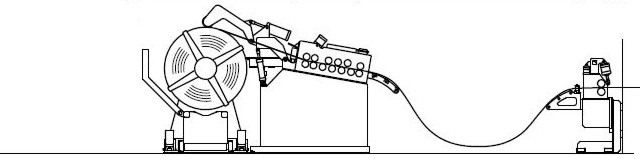

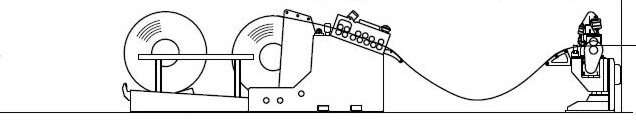

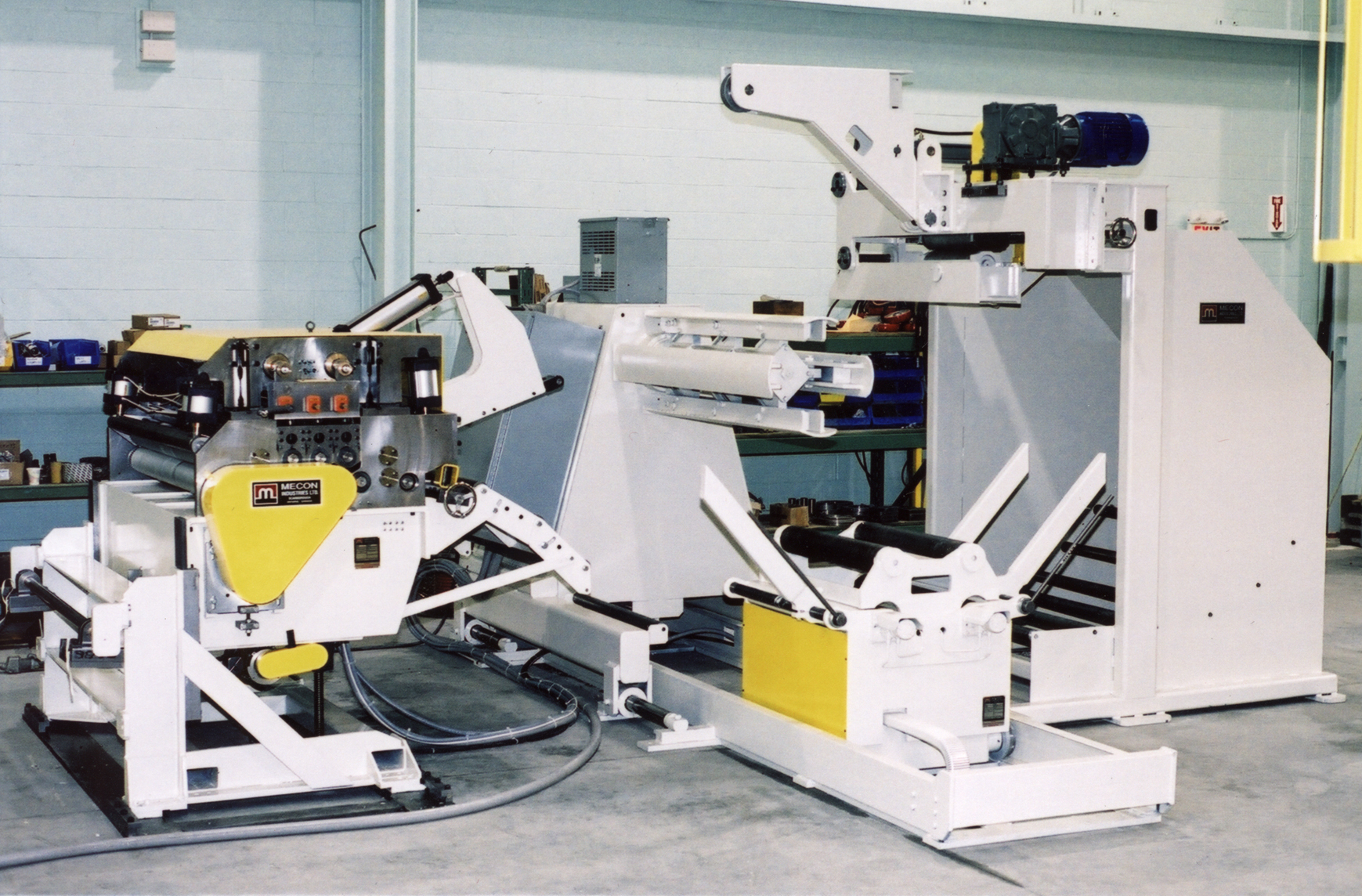

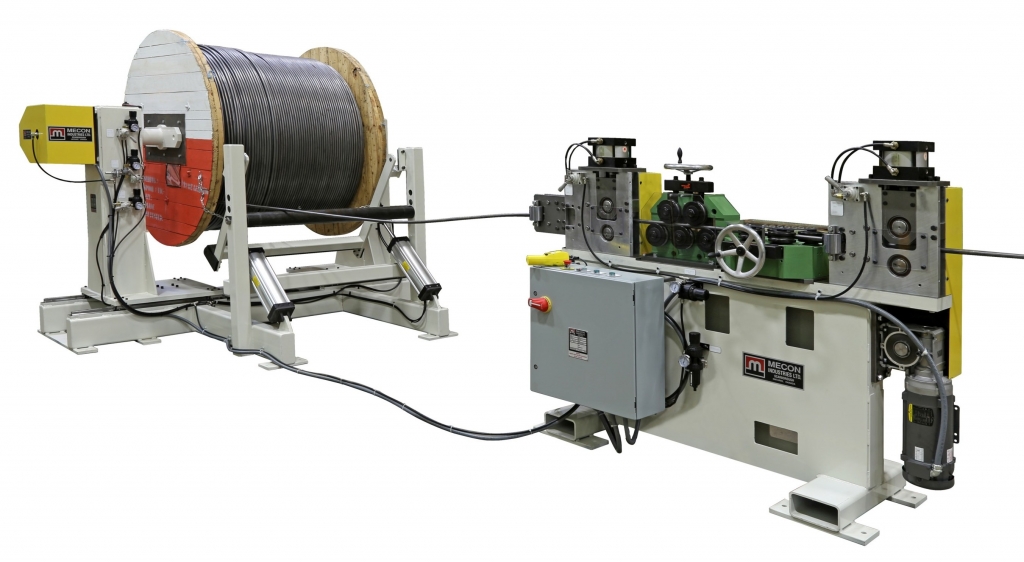

Designing coil handling equipment with Solidworks Coil handling line: uncoiler, straightener, Loop control, console, feeder. A full press feed line

Coil handling line: uncoiler, straightener, Loop control, console, feeder. A full press feed line

- Our engineering and design department is fully computerized. We are constantly looking for new ideas to improve productivity and safety.

- Engineering documents and operating manuals are maintained at Mecon for each machine shipped.

- Teamwork is part of our long-term success. Most of our employees have been with the company for many years. Giving students the opportunity to train in our facility maintains our high level of skilled manpower.

- Mecon engineering and manufacturing have made important contributions to increased productivity in the coil processing industry.

- The building of coil handling and press feeding equipment is not an assembly line process. Each system is an assembly of equipment designed to function together to customer requirements.

- With Mecon, there is a single source responsibility for the client to fall back on. You will know the status of the project and who to turn to with your questions.

- Mecon has modern equipment operated by skilled craftsmen. This man-machine team results in high quality at competitive prices.

- Mecon manufacturing combines fabricating, conventional, CNC machining, grinding and ten-ton material handling capacity. Details and finishing are important – nothing is left to chance.

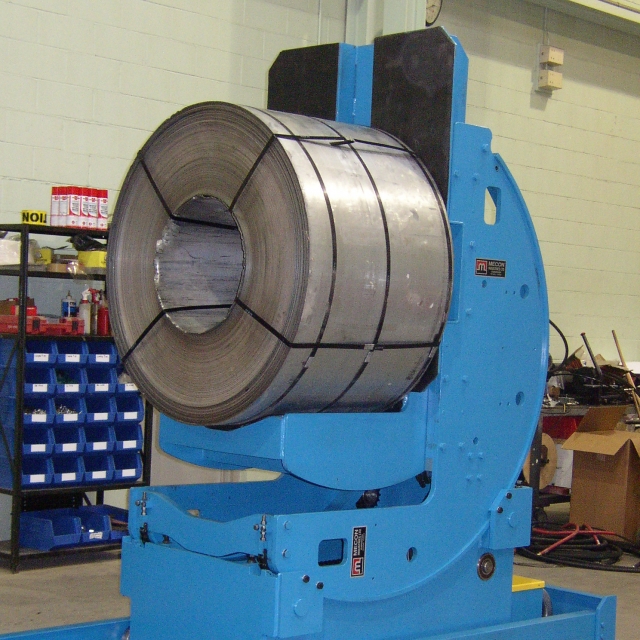

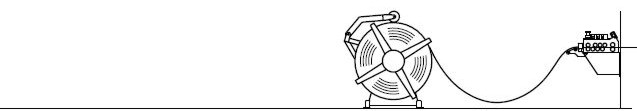

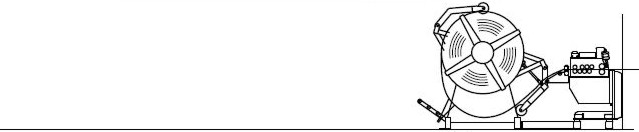

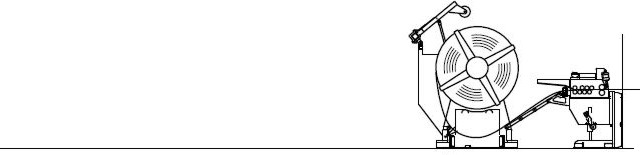

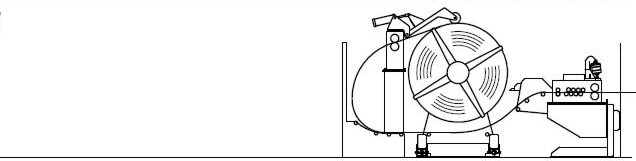

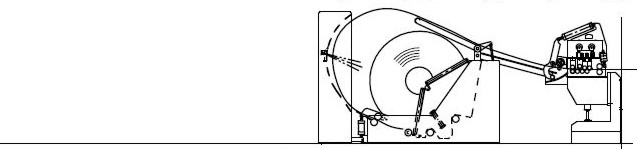

An Upender, part of a Coil handling line

An Upender, part of a Coil handling line

- All design, cutting, machining, and assembly is done in-house to Mecon’s exacting standards.

- All machines must pass factory testing before release to customer.

- Each machine benefits from an engineering review to assure use of the highest quality components and technology, consistent with the best in the industry.

- Final check-over and testing of equipment is completed before shipping.

Interested in finding more information about our coil handling equipment, call +1-416-751-1901, Mecon Industries, the leader in supplying steel coil handling equipment. Our knowledgeable engineering staff will be happy to assist in making the right choice.

Full description of our coil handling technology, please download a copy.

The Material

The internal stresses often vary from the outer wraps to the inner wraps and from the center to the edges. The strip is unwound, slit to width and rewound. Center slit material often yields the best material, edge cuts often yield the worst. When the internal stresses are not balanced, the slit material will have camber. The greater the stress imbalance, the worse the camber. In some instances, additional processing will be necessary to balance the internal stresses and eliminate camber. Poor material is a leading cause of difficulty in tracking the strip through the entire system. Camber problems will consume your profits!

To avoid many coil-handling problems, insist on quality material, reject that which does not meet your standards, and use the proper uncoiling system.

Productivity

Selecting the proper options for your system will provide big paybacks in productivity gains.

- Eliminate waiting time for overhead cranes or lift trucks by installing coil cars and coil storage ramps Coils can be staged when convenient and are ready when the system needs them

- Reduce handling time and increase safety with coil clamping arms and threading equipment

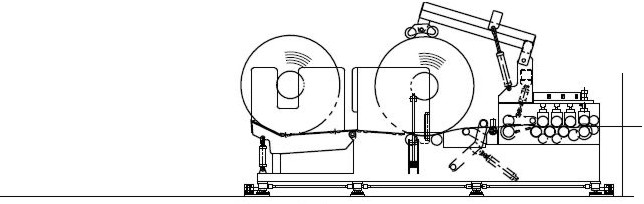

- Use dual spindle uncoilers when feeding high demand systems like rolling mills or systems using partial coils

- Use sonar loop controls to smooth the uncoiling – straightening process, maintain proper loop geometry, and deliver more consistent material to the feeder

- Use a side shift base on the uncoiler to allow easy coil alignment and adapting for camber during processing

- Purchase the best material possible to ensure good quality, consistent parts

SUGGESTED SYSTEM ARRANGEMENTS

Mecon Industries Limited manufactures a variety of coil processing systems.

Many factors should be considered when determining the optimum arrangement.

• Crane capacity

• Lift truck capacity

• Mark sensitivity

• Material width

• Material strength

• Coil handling: – load and unload partial coils, or run full coils to end

• Coil inside diameter

• Coil outside diameter

• Production required: -feed length, speed, feed angle, feed time

• Budget

Coil Lines

LINE 1

- BACK TENSION UNCOILER

- POWERED STRAIGHTENER

- PRESS-MOUNTED SERVO ROLL FEED

LINE 2

- MOTORIZED UNCOILER

- POWERED STRAIGHTENER

- SERVO ROLL FEEDER

LINE 3

- POWERED TRAVEL & LIFT COIL CAR

- BACK TENSION UNCOILER (WITH JOG MOTOR)

- THREADING STAND

- POWERED STRAIGHTENER

- SERVO ROLL FEEDER

LINE 4

- MOTORIZED UNCOILER

- HOLD-DOWN ARM

- SERVO FEEDER-STRAIGHTENER

LINE 5

- MOTORIZED UNCOILER

- UNDER PADDLE LOOP CONTROL

- SERVO FEEDER-STRAIGHTENER

LINE 6

- POWERED TRAVEL & LIFT COIL CAR WITH IDLE ROLLS

- MOTORIZED UNCOILER WITH SONAR LOOP CONTROL

- OVERARM WITH COIL GUARD

- SERVO FEEDER-STRAIGHTENER (WITH THREADING OPTION)

LINE 7

- POWERED TRAVEL & LIFT COIL CAR WITH IDLE ROLLS

- BACK TENSION UNCOILER (WITH JOG MOTOR & SIDE SHIFT)

- PULL-OFF PINCH STAND WITH OVER-ARM

- COIL GUARD

- FEEDER-STRAIGHTENER

(WITH THREADING OPTION)

LINE 8

- COIL CRADLE

- COIL THREADING AND PREBENDER

- SERVO FEEDER STRAIGHTENER

LINE 9

- COIL STORAGE RAMP

- COIL CRADLE STRAIGHTENER

- SERVO ROLL FEEDER

LINE 10

- COIL CRADLE STRAIGHTENER (WITH THREADING OPTION)

- FLOOR-MOUNTED SERVO ROLL FEED

LINE 11

- SERVODRIVEN COIL-CRADLE-STRAIGHTENER-FEEDER

- HEAVY DUTY DEKINKER AND COIL THREADER

- WITH COIL STAGING RAMP

- SIDE SHIFT BASE

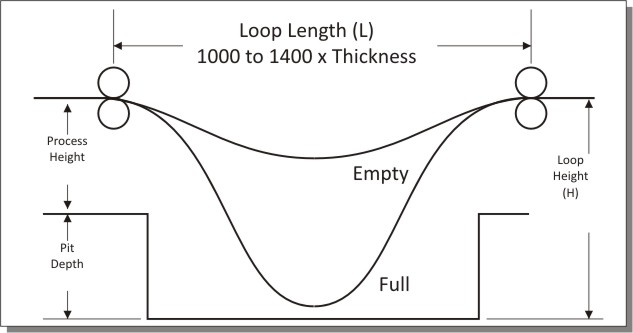

ACCUMULATION LOOPS and PITS

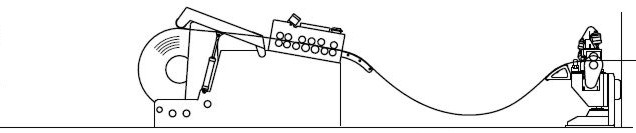

Most systems require an accumulation loop. The accumulation loop is used to allow the uncoiling process to payout at a nearly continuous rate while the feeding equipment stops and starts. Ideally the loop will accumulate at least 2 feed lengths of material. Thickness, material yield strength, and feed length are important factors to consider when determining loop geometry. The loop must store sufficient material to allow smooth operation. The material must not be curved smaller than the minimum bend radius to ensure that the proper loop shape is maintained and kinking does not occur:

• The loop length should be 1000 to 1400 times the material thickness.

• Ramp rolls should support the material as it enters and exits the loop.

A pit is recommended if the required LOOP HEIGHT, is greater than the process height

MECON HOME MECON COIL HANDLING MECON COIL HANDLING EQUIPMENT

Download Catalogue

The Uncoiling Problem

The strip is slit to width. When internal stresses are not balanced, the slit material will have camber. The greater the stress imbalance, the worse the camber. Camber is a leading cause of difficulty in tracking the strip through the entire system. To avoid many of the problems of coil handling, insist on quality material, reject that which does not meet your standards, and use the proper uncoiling system.The Two Basic Systems

Electronic Roll Feeding

Ease of set up is a key feature. ERF’s take less time to set up than mechanical feeds and trial and error adjustment: at the control panel, just enter feed length, speed, and press “start.” Mecon will size the drive and set the acceleration and deceleration to best match the production requirements.

When possible, lower accelerations and speeds are used. This gives increased accuracy, smoother material flow, and eases the load on the uncoiling system. Another outstanding advantage of the ERF units is their ability to easily adapt to the press feed angle.

.

MECON HOME MECON COIL HANDLING MECON COIL HANDLING EQUIPMENT

Download Catalogue

WHICH UNCOILING METHOD IS BEST? REEL OR CRADLE

Both types of uncoiler have advantages and limitations. In general, the reel works well with thin to thick material, the cradle works well with thicker materials.

- Material is sometimes thinner than 0.080″

- Rewinding full or partial coils

- Precise tension control is necessary

- Material marking is critical

- Straightener is pulling the material off the coil

- Powered uncoiling of materials thinner than 0.150″

- Material is always thicker than 0.080″

- Rewinding is not important

- Tension control is not important

- Material marking is not critical

- Powered uncoiling of materials thicker than 0.150″

Coil Reels

Coil reels are used as uncoiling devices’ because they inherently avoid stock deformation problems. The stock is supported on the center core of the coil and is unreeled as required. Mecon Industries, a coil reel manufacturer in Toronto, provides rugged and proven designs for uncoilers that require minimum maintenance and have a long operating life. Check our online uncoiler catalog to see detailed technical data.

REEL UNCOILER SELECTOR GUIDE->

ADVANTAGES

- Coil reel is suited to uncoiling a wide ranges of material

- Coil reel is easily able to maintain programmed tension downstream

- Can be drag braked or powered unit

- Coil reel can be adapted to uncoil or recoil

- Can easily rewind unused material

- Coil reel is less costly than cradles

DISADVANTAGES

- Coil core may be required for thin materials.

- Overarm necessary for thick materials.

- Material loops required between machines.

- Coil reels are less tolerant to misalignment.

- Accepts limited range of internal coil diameters.

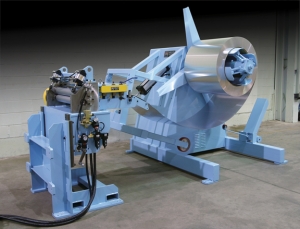

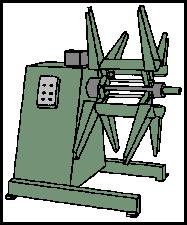

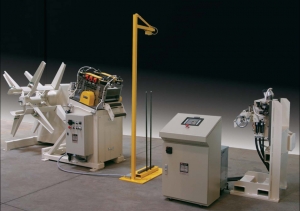

Motorized Double Reel Uncoiler with Overarm

Mecon Industries has been building coil handling equipment for years.

If you looking for an uncoiler manufacturer , Mecon Industries has the right system for you. Our advanced technology and experienced staff have been designing, engineering and manufacturing coil handling equipment since 1963! We know what it takes to produce the industry best uncoiler systems.

Some examples of our uncoilers are presented below. You can find the following models of coil reels: Motorized Double Reel, Motorized Reel, Motorized Reel with Coil Car and Overarm. Call to discuss your requirement.

Motorized Reel Uncoiler

Motorized Reel Uncoiler with Coil Car and Overarm

Motorized Reel Uncoiler with Coil Car and Overarm

Coil Cradles

Easy, fast loading of coils is the single most important benefit offered by cradle-type uncoilers. They are often used in combination with straighteners for faster loading and adjustment, low power requirements and maintenance. Cradle-straighteners also save plant floor space.

DISADVANTAGES

- Must be powered. Not suited to a drag pull-off system.

- Can be difficult to rewind unused material.

- Cradles are not recommended for use with pre-finished stock, or soft material, as weight of coil on rollers may cause surface marks or deformation.

ADVANTAGES

- Suited to process thick material.

- Easy and safe loading of coil.

- Accepts any range of coil I.D., and wider ranges of O.D.

- Confinement of coil helps in control of heavy materials.

- Straightener is easily built-in and synchronized with process speed.

- Suited to addition of threading systems for routing of heavy materials into feeds.

- Can be relocated to more than one work area.

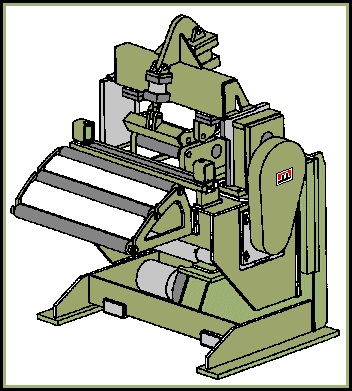

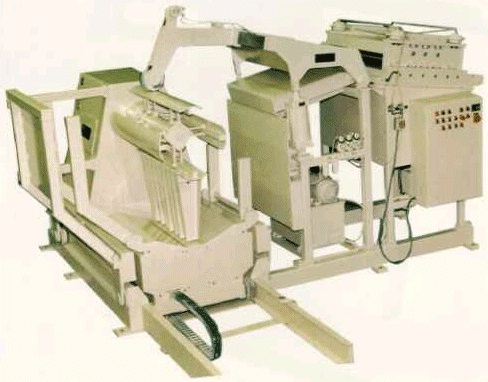

Uncoiler Cradle-Straightener combination with coil ramp

Uncoiler Cradle-Straightener combination with coil ramp Uncoiler Cradle-Straightener combination

Uncoiler Cradle-Straightener combinationIf you need more information from the experts, please give us a call at +1 (416) 751-1901 to discuss your process requirement with our knowledgeable engineering staff . You can also request a quote via Coil Handling Equipment Quotation form.

Uncoiler: Reels-Single and Dual spindle:

The coil reels used in most uncoiling and recoiling applications, primarily because they inherently avoid stock deformation problems. The stock is supported on the center core of the coil and is unreeled as required. May be fitted with a variety of drive and braking systems, combined with coil cars, pinch rolls, power straighteners, overarms, rolling mills or configured as stand alone systems. Reels are the best choice for thin, prefinished and other mark sensitive materials.

Advantages:

- Coil reel is suited to uncoiling a wide ranges of material

- Coil reel is easily able to maintain programmed tension downstream. Can be drag braked or powered unit

- Coil reel can be adapted to uncoil or recoil. Can easily rewind unused material

- Coil reel is less costly than cradles

Coil Cradles

Easy, fast loading of coils is the single most important benefit offered by cradle-type uncoilers. They are often used in combination with straighteners for faster loading and adjustment, low power requirements and maintenance. Cradle-straighteners also save plant floor space.

Features:

- Rugged heavy duty steel construction

- Self centering coil keeper plates

- Lifting points for crane

- Forklift truck lifting tubes

- Driven cradle and straightening rolls

- All rolls hardened to 55RC

- All lubrication points marked and easily accessible

- Capacities from 0.060” to 0.375” mild steel, 12” to 72” (larger sizes call for quote)

- Standard payout speed of 0 to 80 fpm.

- Digital indicators show straightener roll position

- Standard straightener head with entry and exit pinch rolls and 7 straightening rolls. (available for new high strength steels)

Advantages:

- Suited to process thick material.

- Easy and safe loading of coil.

- Accepts any range of coil I.D., and wider ranges of O.D.

- Confinement of coil helps in control of heavy materials.

- Straightener is easily built-in and synchronized with process speed.

- Suited to addition of threading systems for routing of heavy materials into feeds.

- Self contained, easy to relocate and setup.

Cons:

- Rewind of unused material may be difficult

- Not recommended for use with thin, prefinished, or mark sensitive materials

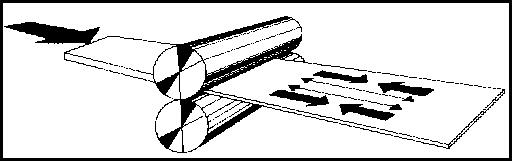

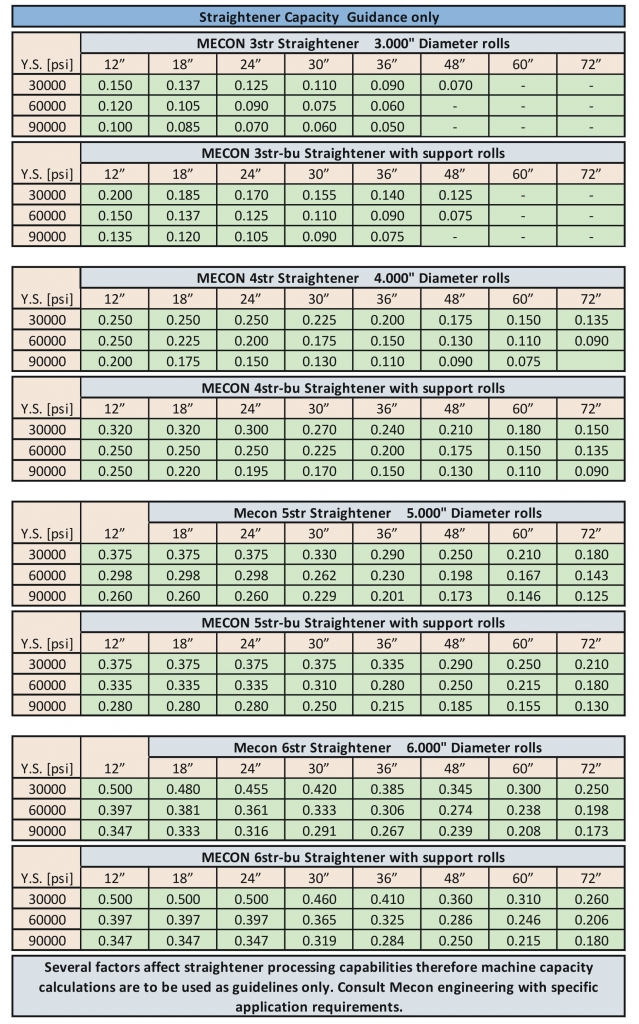

NEW Rules New Tools: Powered Straighteners

The new HSLA materials being used in the industry are posing new challenges for coil handling. Straighteners must be sized on the basis of the type of material to be processed, the thickness range, the stock width, and Yield Strength. Straighteners are generally positioned close to a non-motorized reel to pull material directly off the coil. The primary function of straighteners is to remove coil set and cross bow, and to pay out material to the accumulation loop as required for the feeder. For most materials and flatness requirements, use straighteners with five to seven rolls. For some materials, and to meet high flatness requirements, more rolls may be necessary.

Mecon straighteners are:

- Easy to thread, with variable speed drives.

- Able to match process demand automatically.

- Heavy duty construction.

- Easy to set, with soft starts and stops.

- All lubrication points marked and easily accessible.

- Capacities in mild steel from 0.010” to 0.450”, 12”-72” wide (heavier on request)

- Standard payout speed of 0-80 fpm.

- Digital indicators show straightener roll position.

- Entry side guide rolls.

- Entry and exit support rollers.

-

Optimized for HSLA materials

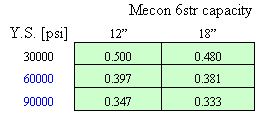

Straightener Capacity

Note: Several factors affect straightener processing capabilities therefore machine capacity calculations are to be used as guidelines only. Consult Mecon engineering with specific application requirements.

Roll Feeds

Mecon feeders use precision Servo motors and controls, precision drive systems and heavy duty components to provide quick accurate indexing of material. They are designed to pull from an accumulation loop (not directly off the coil), and accurately position the material each cycle.

Fast, Flexible Operation. RThe controls are located on a console or pedestal for convenient entry of job settings. Setup time is reduced to seconds, just enter the values using the keypad. Roll positioning accuracy of +/_ 0.002” can be achieved with the sevro driven roll feeds. The drives provide precision control of position, speed, acceleration and deceleration.

- Features:

- Diagnostic display of operating status and faults

- Feed before press or press before feed modes.

- Upper feed roll is driven is driven using a constant mesh 4 gear train, gears are hardened 4140 steel

- Hardened vertical side guide rolls align the strip to the tooling

- Entry ramp rolls support material to ensure smooth flow from loop to feeder

Accurate Part-to-Part Advancement

Roll position accuracy of .001 (inch) can be achieved with Mecon electronic roll feeds. Servo drives provide gradual, and controlled, acceleration and deceleration. Stock payout is smooth and rolls do not slip.

SERVO FEEDER SELECTOR GUIDE ->

High Capacity, High Performance Machine

High Capacity, High Performance Machine Feeder with Anti-Backup Option

Feeder with Anti-Backup Option Feeder on Floor Base with Exit Table

Feeder on Floor Base with Exit TableSide Shifting Feeders

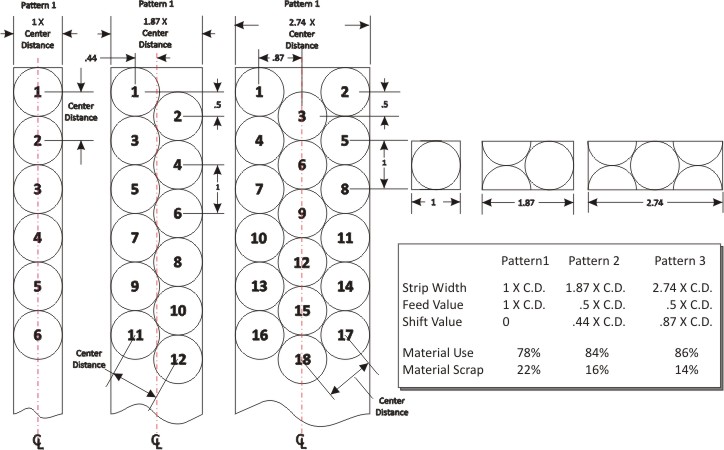

Mecon offers roll feeds with a servo driven shift base to allow optimum use of material.

The standard control has 3 pre-prograrnmed patterns. Shift and Feed distance are simply keyed in at the operator’s console. Select the pattern, press start and the machine is ready to run. Custom programs available.

Side Shift Feeder on Floor Base

Feed and Shift patterns

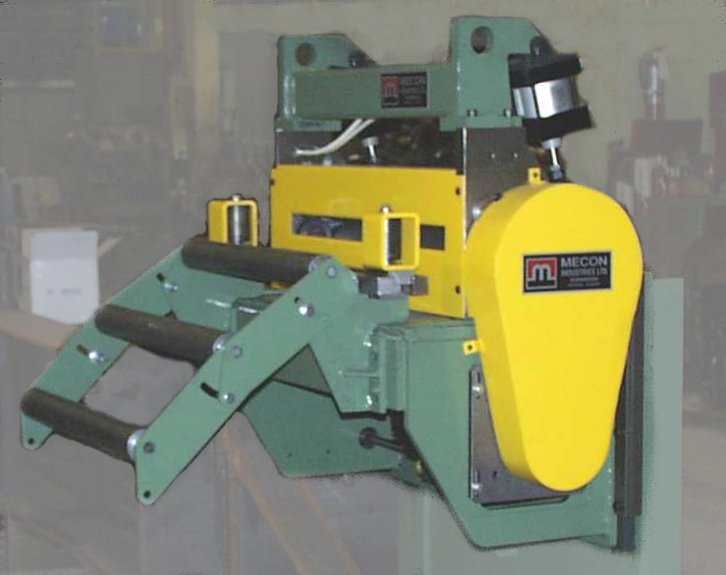

Feeder Straightener Combinations

These double operation units have become more accurate and faster as high performance motors have become available. Accuracy is now comparable to stand alone feeders. They are designed to straighten and feed material from a powered uncoiler.The material is being processed closer to the press with the coil being fed directly into tooling. The positioning of the material is accurate and coil set is eliminated.

Feeding of a new coil stock through the straightener is accomplished without opening the straightener head or disturbing the depth settings. Straightener-feeder combinations save space.

Feeder With Pull-Through Straightener

Feeder With Pull-Through Straightener

Feeder With Driven Straightener

Feeder With Driven Straightener

Feeder With Driven Straightener Pilot release of feed and straightening rolls. Threading option.

Feeder With Driven Straightener Pilot release of feed and straightening rolls. Threading option.

Customized Purpose Built Uncoiler Systems

Coil Car, Dual Spindle to Reduce Down-Time, Cut to length line with Rotating Shear

Coil Car, Dual Spindle to Reduce Down-Time, Cut to length line with Rotating ShearReduced downtime for coil changeovers may make the difference between profit and loss. Fast loading, easy “hands-off” operation makes for a streamlined, safe and profitable operation. …see more

Powered Straightener with Drag Reel, Laser Loop control, Servo feeder floor mount.

Powered Straightener with Drag Reel, Laser Loop control, Servo feeder floor mount. Pipe Uncoiler with Straightener

Pipe Uncoiler with Straightener Coil Car, Uncoiler, Threading Equipment, Powered Straightener

Coil Car, Uncoiler, Threading Equipment, Powered Straightener

The Space Saver

Space Saver Combination with Coil Car, Uncoiler, Roller Coil keepers, Power Pull off Rolls, HSLA Threading, Servo Pilot release Feeder-Straightener

Space Saver Combination with Coil Car, Uncoiler, Roller Coil keepers, Power Pull off Rolls, HSLA Threading, Servo Pilot release Feeder-StraightenerMain features:

- Single operator.

- Easy to load.

- Hands-free threading for safety.

- High capacity / high performance.

- Compact – saves floor space.

Anatomy of a Coil System

Consider these options to maximize production with safety:

- Coil Car

- Upenders

- Threading Table

- Hold Down Arm

- Material Guidance

- Shear

- Stacking Pallets

- Part Conveyors

- Multi-Function Pendant

- Feeder Exit Table

- Side Shift Base

- Laser Loop Control

Coil Car with Narrow Coil Keeper Arms

- Typical power lift of 20″, 110” travel 1,000 to 60,000 lbs.

- Dual scissor stabilizer to support top of car when loaded off center

Material Guidance systems

- Screw adjust side side guides help hold the material square and centered as it enters the straightener.

- Screw adjust side guides are selfcentering, roll position is set by hand wheel.

Multifunction pendant

- Multifunction pendant (replaces standard 2 button jog pendant)

- Mode select: Setup- Manual- Automatic, Reset, Feeder Auto start, Feeder Auto stop, Jog Reverse, Jog Forward

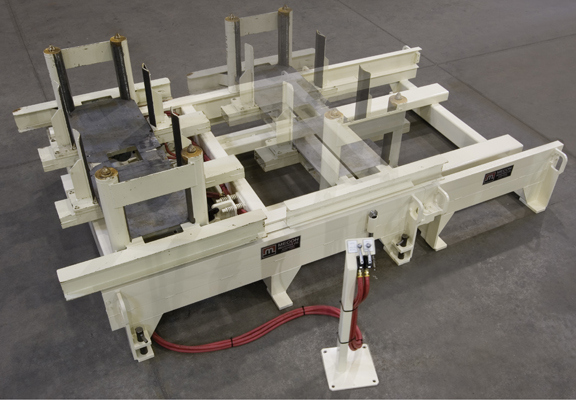

Coil System Threading Table

- Eliminate the need for the operator to carry the start of the material from the coil to the straightener

- Safe material handling operation

Mecon Laser Loop Control System:

- Controls the uncoiling process to supply material into an accumulation loop at a rate sufficient to meet or exceed the demands of the machine pulling material from the loop.

- Provides a simple method of setting the operating limits, the operating parameters, and the mode of the loop control.

- Allows the uncoiling process to run without abrupt changes in speed.

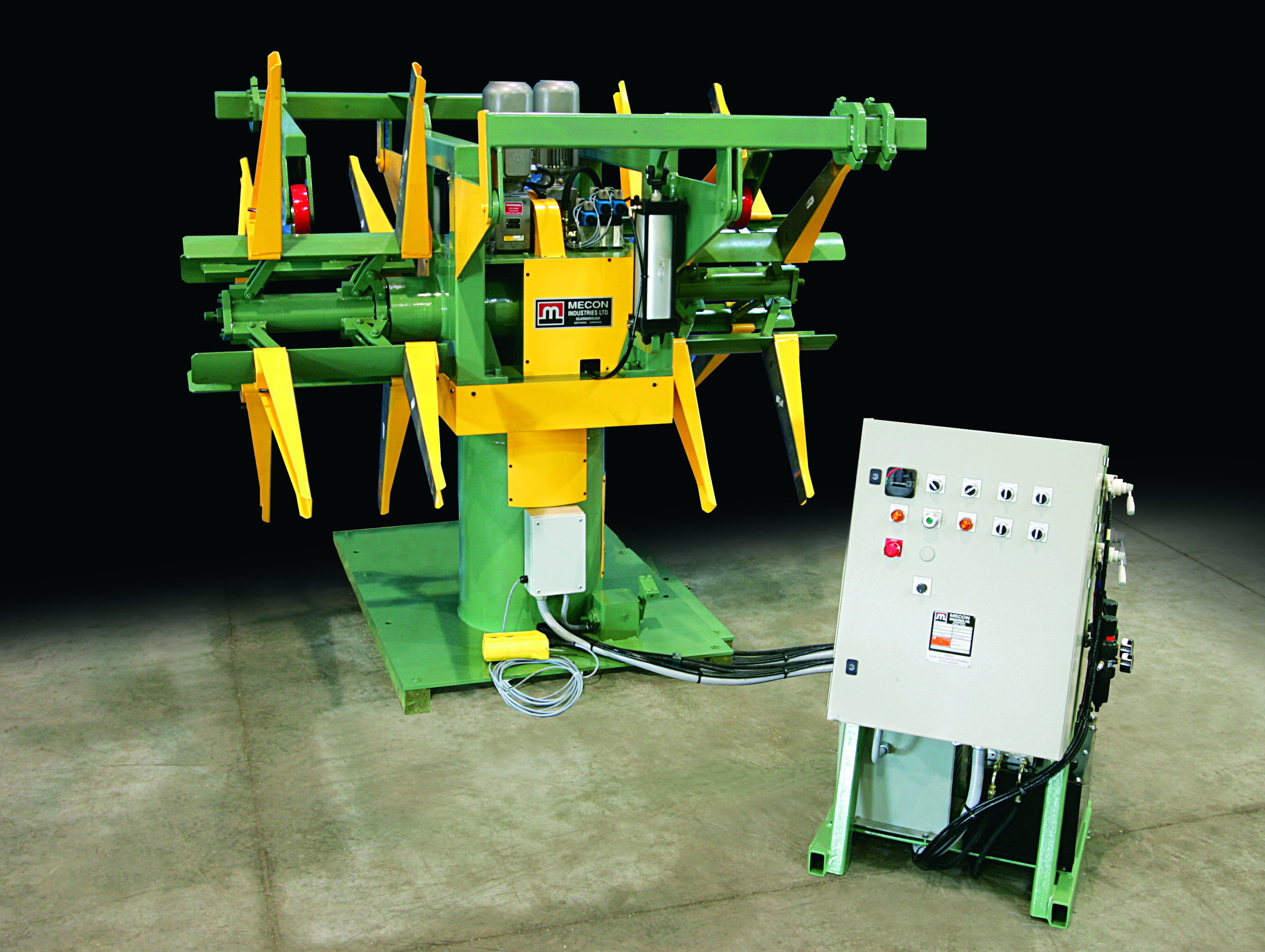

Coil Upender

- Easy and safe way to upend not only metal coils, but also molds, dies and other heavy and bulky loads.

- Available 1,000-60,000lbs standard, custom to you requirement.

Shear

- Modular construction to allow easy integration

- CRU-WEAR High chrome, high carbon tool steel shear blades with 4 cutting edges 1/2 x 3″.

- CYCLE TIME less than 1.5 sec.

Perimeter Safety Fencing

- 2.5″ sq. posts lagged to the floor.

- Spaces between are posts fitted with panels 1.5 x 1.5 angle frame and 10 ga. x 1 x 1 welded wire.

- Fixed panels are bolted in place. Any fixed panel may be removed by unbolting.

- Sliding or hinged doors may be placed anywhere in the perimeter/

- Telescoping doors and light curtains available

- Fully programmable multiple Safety Zones

Stacking Pallets

- Adjustable posts to align blanks for stacking.

- Sub frame with cross tubes for lift truck forks and corner posts for stacking.

- Guide posts mounted on Tee Slotted bars for positioning

- Guide posts mounted on sliding and pivoting bases.

- Custom designed for your requirement.

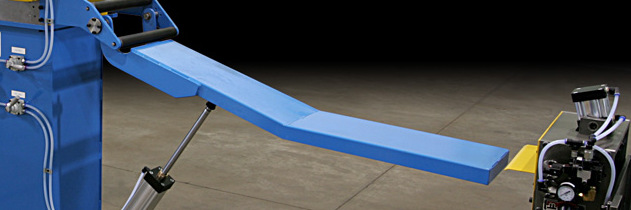

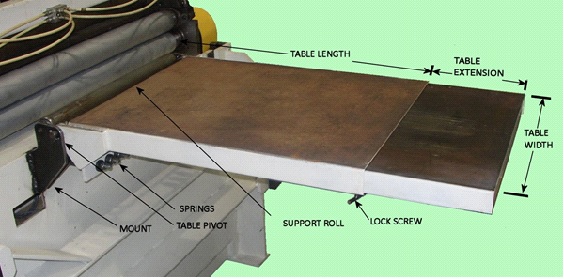

Feeder Exit Table

- This version has a solid top, spring suspension, and is extendable

- Options: mount for strip lubricator, roller top, nylon top, …

- Design to suit site requirements.

Examples of Steel Coil Handling Systems by Mecon Industries Ltd.

Catalogues

Catalogues

Typical system requirements and proposed solutions:

#15409 20Klb x 48 CTL#11233 20Klb x 18 HSLA

#3120 50Klb x 72 Conventional

System #15409

Requirement:

Cut to Length System, Single uncoiler with Coil cart

- 10,000 lb x 48” wide capability

- Material thicknesses:.015”-.060”

- Material: galvanized, galvalume, cold-rolled steel, stainless steel (304, 316, 409, 430, AL29-4C, other) Note: Majority is SS material

- Min/Max coil width: 24”/48”

- Existing available floor space to work within: 35ft long x 10ft wide.

- Min/Max cut length: 9”/51”

- Production rate: 1500 blanks per hour (22” avg cut length)

- Loop control sensor

- Threading table

- Powered straightener

- Servo roll feeder (feed roll accuracy of +/-0.002”)

- Precision Shear

- Shear blade material with high wear resistance (i.e. Cru-wear)

- Minimal shear blade change time (

- 5’ x 5’ Blank stacking system (that will not damage sheared edge) Blanks muststack directly onto existing metal pallets used for laser welder. (See below).

- Quick/easy coil changeover

Important Considerations:

Tight tolerance on length.

Out of square causes problems

Flatness

Rewinding of partial coils

Coil Handling streamline and automate

Stacking system, even stacking very important

Minimize marking.

Proposed Solution:

Coil car – 200cc with Coil keeper arms

- 20,000lbs capacity, 19″ vertical lift, 120″ travel

Uncoiler – 200m60

- 20,000lbs. capacity

- 60”, 4 segment mandrel with hydraulic expansion 18” to 22” diameter

- Overarm with idle wheel

- 100” travel base with tractor drive

- Overarm with idle wheel

- End Pivot, hydraulic lift threading table EPH 60 x 150

- The threading table is used to eliminate the need for the operator to carry the start of the material from the coil to the straightener .

- Extended entry conveyor with ramp .

- 2 sets side guide rolls with centering screw adjust .

- Coil centerline laser .

Combination Feeder Straightener – 4str60 .

- 11 hardened and ground rolls running on precision needle bearings,

- Bearings lubricated from centralized manifolds (hand lubricated)

- Entrance and exit pinch rolls; air actuated, lower rolls driven,

- 2 entrance pinch rolls, 4.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading,

- 2 exit pinch rolls, 4.000″ diameter, open for threading, close for running, servo drive with 575v to 440v transformer

- Flex system control HMI with I/O for shear control

- Exit side guide rolls with centering screw adjust .

Shear – 08hs60

- MAXIMUM WIDTH 60″

- THICKNESS .080″ AT 60″ WIDE 60,000 UTS MILD STEEL

- THICKNESS 0.004″

- CYCLE TIME 2 seconds

System #11233

Requirement:

1 coil feed system for 3/4”material.

- 20,000 lb x 18” wide capability

- Material thicknesses: up to 3/4″, see below

- Material width: 18″ max.

- Press speed: 20 SPM

- Feed length: Various

- Feed angle: to be determined

- Coil OD.: 72″ max.

- Coil ID.: 18-22″

- Passline: 54″ to 57″

- Quick/easy coil changeover

ys < 30,000 psi

- 1008/1010

- 0.642″ x 8.06″

ys 30,000 to 60,000 psi

- 4130/4140

- 0.414″ x 8″

ys 60,000 to 90,000 psi

- 5120

- 0.508″ x 4.4″

Proposed Solution:

The system offered is comprised of a combination coilcradle-feeder-straightener. The coil cradle and feeder-straightener are both driven by servodrives. The system is designed to run with no loop, the cradle drive and straightener drive are matched electronically.

The servo-drive responds to the press cam switches, and feeds an exact amount each press stroke.

Model 200CSF18 Coil-cradle-straightener-feeder

-CAPACITY 20,000 LB.

-MAX. OD 72″

-MIN. ID 18″

-MAX. THICKNESS see chart

-PASSLINE HEIGHT 52″ TO 58″ POWER ADJUSTMENT

Based on review of the most difficult materials on the specification list we recommend the 8str18 straightener.

Machine frame and drive sizing will match the straightener capacity listed for the 8str18 series straightener.

COMPONENTS.

- Coil Staging Ramp: The coil is set onto a fabricated Vee table with a pivot. Hydraulic cylinders lift the table upward to create a 5 degree down slope to the cradle rolls, or down for staging. A coil catcher / peeler catches and cushions the coil as it rolls into place on the cradle rolls. Coil catcher may be used to push the coil off the cradle rolls to the staging station.

- Side Guidance: Side walls on both sides of the coil are set to coil width to contain the coil and reduce telescoping. Side guide rolls are set in the walls beside the cradle rolls to reduce friction between the coil and the wall during feeding. Wall position is set by limit screws and open / closed by hydraulic cylinders. Walls open to rated coil width plus 10” to allow cutting and removing of coil retaining bands.

- Vertical side guide rolls are set at the entry of the straightener

- Coil overarm: Telescoping overarm with dual rollers is set to hold the coil down onto the cradle and help contain the coil when the bands are cut. Actuated by hydraulic cylinders.

- Cradle: The coil is supported on 2 hardened cradle rolls X 7.750 inch dia..

- Cradle rolls are driven by a servo-gearmotor

- Cradle side plates are self centering and are power adjusted.

- Threading system: Peeler / prebender pivots and extends to the side of the coil to guide and wrap the start of coil over the ramp rolls mounted between the cradle and the straightener. The entry pinch roll opens to catch the start of coil, closes to grip and drive the material through the straightener.

- Feeder-straightener: model 8str18 Rolls are 1045 steel, 10.000″ diameter, induction hardenned to 56-58 Rc, and diameters are precision ground. Bearings are Heavy Duty rollers running on hardenned inner races with seals.

- 6 roll straightener: 3 upper rolls over 3 lower rolls.

- Lower rolls are driven and fixed position

- Upper rolls are not driven and are individually adjustable.

- Straightener rolls are adjusted by hydraulic motors, roll position is indicated by digital counters with .001″ resolution.

- Rolls are 1045 steel, 10.000″ diameter, induction hardened to 56-58 Rc, precision ground, shot peened and chrome coated for excellent wear resistance and grip

- 2 entry pinch rolls, upper and lower roll driven, grip the strip to drive material thru straightener without resetting. Rolls open up 3″ for easy threading.

- 2 exit feed rolls, upper and lower roll driven, grip the strip to drive material thru straightener without resetting.

- Lift system: The machine height is set by motorized worm screw jacks with 6″ adjustment. Jack feet are set onto floor pads. 2 guide posts mounted to the front mount plate prevent side movement.

- Controls: Control console contains the operator buttons and drive system including;

- Pendant jog control to allow operator to position strip from a remote location.

- Power on, Cradle sides in/out, Emergency Stop, Drives on/off, Roll controls, Cycle start/stop, Mode selection, Length and speed inputs, main power disconnect.

- Feed to length control requires a Press Operated Control Relay (Feed Cam) to close at start of feed, and remain closed until feeding is not permitted.

- Servo system – Bosch Indradrive, Yaskawa or equivalent, HMI to allow programming of system parameters, feed length, speed, and display of operating mode, fault status and code.

- Optional – side shift system: The machine will be mounted on sideways slides and shifted by hydraulic cylinders. Front and rear are set independently with position indicated on scales.

Requirement: 50,000 lbs. x 72” wide Steel coiled material to be stored, uncoiled, straightened, and fed into a press.

Maximum coil weight: 50,000 lbs.

Min/Max coil I.D.: 19 ½” -24 ½”

Max coil O.D.: 72”

Press: PTC

Passline ht: to be determined

Feed angle: 180 degrees

Material: .020″ to .236″ (6mm) mild steel and hsla,

Material: .08 x 60″ 50ksi ys steel

Material: .120” x 72” (3 mm) x 50 ksi,

Material: .177” x 56” x 50 ksi ys HSLA

Performance: 15” x 48 spm, 24” x 30 spm

Power supply: 480 volt, 3PH, 60Hz

Air supply: 80 psi

Proposed Solution: Coil car, Uncoiler, Power Straightener, accumulation loop, Feeder.

a) Coil car model 500cc with power top rolls:

- A coil car with power lift of 20″ and power travel.

- The car will travel on tracks to transfer the coil from the park position to the uncoiler, or from the uncoiler back for storage. The coil rests on non-powered rollers.

- The rolls are used to aid in threading thicker materials into the straightener. Traverse, and lift functions are controlled manually from a central control station.

b) Uncoiler model 500btj72. ( capacity 50,000 lbs x 72” with spindle end support)

- The uncoiler has an air brake to maintain coil tension during processing.

- A hydraulic motor, and clutch for jogging coil. Jog speed 4 rpm.

- Upgrade to heavy duty back tension brake with coil diameter sensor to maintain constant tension during unwind of coil.

- The mandrel is 4 segments, with wedge style expansion and is hydraulically expanded/retracted.

- Inside diameter range of 19.5 to 24″.

c) Coil over arm with power wheel: Peeler / coil breaker.

- The over arm clamps onto the coil to contain the coil end when the straps are cut.

- The wheel is powered by a hydraulic motor and drives the coil to thread the start of the coil to the input pinch rolls of the straightener.

- The Peeler extends to contact the coil and guide the start of the coil.

- The coil breaker lifts to press the strip against a flattenning block on over arm and thus de-kink the start of the strip. This allows easy threading of steel into straightener.

d) Straightener model 5str72-bu: Series straighteners have:

- 11 hardened and ground rolls running on precision needle bearings, bearings lubricated from centralized manifolds (hand lubricated)

- Entrance and exit pinch rolls; air actuated, lower rolls driven.

- 2 entrance pinch rolls, 5.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading.

- 2 exit pinch rolls, 5.000″ diameter, open for threading, close for running.

- 7 straightenning rolls, 5.000″ diameter, 4 lower rolls all driven, 3 upper rolls idle.

- Upper rolls motorized individual adjustment, position shown on .001″ graduation counters.

- Straightener drive: Variable Frequency AC Motor control with AC induction motor, and brake.

speed 0-80 fpm. infinitely variable. These drive systems give very smooth acceleration and deceleration with no sudden shocks to the material or drive components, and thus extend machine life and limit material marking. - In automatic mode a sonar unit senses the height of the material in the loop between the straightener and the feeder.

- The sensor signals the drive to speed up or slow down to maintain the loop automatically.

- The uncoiler brake is provides back tension to limit coil overrun and to help prevent coil slack.

- n manual mode the speed is set at a low speed and forward or reverse movements are selected by pendant mounted switches.

- HD Support rolls: The drive system will be increased to 40 hp to match the higher capacity of the straightener. Each straightener roll is supported by rolls to limit roll deflection when processing heavy materials. Lower support roll positions are fixed and not adjustable. Upper support rolls travel with the straightener roll during adjustment.

- Material guidance: Coil peeler and breaker guide material into straightener.

- Entrance vertical guide rolls to track the material.

- Exit ramp rolls support strip as it exits straightener and drops into loop.

| Model 5str72-40 hp with support rolls | ||||||

|---|---|---|---|---|---|---|

| 24" | 36" | 48" | 60" | 72" | ||

| yield 30,000 psi | inches | .375" | .375" | .290" | .250" | .210" |

| yield 60,000 psi | inches | .316" | .283" | .245" | .211" | .177" |

| yield 90,000 psi | inches | .283" | .253" | .219" | .189" | .158" |

System Summary:

a) COIL CAR: MODEL #500CC .

- 20″ lift .

- Keeper arms .

- power rolls .

b) UNCOILER: MODEL 500BTJ .

- 72″ mandrel .

- side shift uncoiler .

- xHd btj base .

- coil diameter brake control .

c) THREADING: MODEL HD72 .

- motorized overarm wide roll std

- coil breaker table std

- peeler arm std

d) STRAIGHTENER: MODEL 5STR72 .

- 40 HP VFAC drive .

- power adjust strnr .

- Stnr support rolls .

- main transformer .

- Sonar loop control .

e) END PIVOT THREADING TABLE:

f) SYSTEM INTEGRATION:

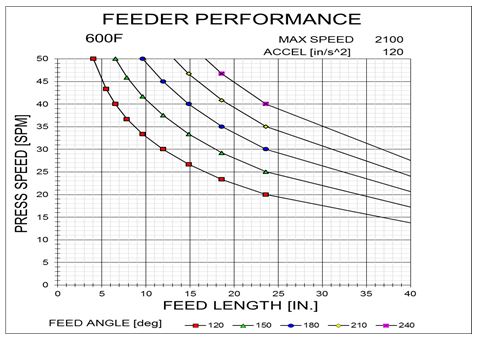

g) FEEDER: MODEL 600F72-IHD

- floor base power elevation .

- 3 ph. isol. transformer

h) Estop and Gate monitor circuits .

- Hydraulic cylinders actuate the table. The table lifts to support material between the straightener and the feeder as the beginning of the strip is being jogged to the feeder.

- Table length is dependent on the loop geometry, which is related to the maximum material thickness, material strength and feed length.

f) Straightener control station and integration:

- Contains the controls for the coilcar, uncoiler, overarm/peeler/breaker station, the straightener, and the threading table.

g) Feeder model 600f72-IHD: The feeder is a floor mounted machine with a press adapter bracket, a seperate control console and a remote jog pendant. The press adapter bracket rigidly attaches the feeder to the press. The jog pendant allows the operator to walk with the material when threading.

- Feed Rolls: The rolls are 73.5″ face width x 6.000″ diameter. They are hardenned, precision ground and 100rms chrome surfaced for excellent grip and wear resistance.

- Upper and lower rolls are both driven.

- Passline Adjustment; Passline height is adjusted by a powered elevator, total adjustment 12″.

- Pilot release: The feed rolls are pnuematically lifted and lowered. The pilot release circuit is signalled by a press cam to lift the rolls and lower the rolls to release the material.

- Anti-Backup brake mounted on the motor is standard. The brake is spring engaged and is on anytime the power is off the servo motor. When the pinch rolls are contacting the strip, the brake will not allow the material to slip back into the loop.

- Servo-Drive: An Indramat high performance brushless AC servosystem drives the feed rolls. It is conservatively rated and is capable of peak torques well in excess of the rated torque.

- The servo motor is mounted to a servo quality “zero” backlash gearbox, and mounted under the feed rolls. A high performance Gates Polychian drive connects the gearbox output shaft to the lower feed roll. Components Mkd Motor, Alpha Sp gearbox.

- Computer Control: An Indramat motion control – Mecon OCS control runs the servodrive. It is very flexible. Program parameters, speed and feed length, etc. are input directly through keypad. Displays operating mode, error and system diagnostics, etc.

- Very fast setup of next job.

- Die and press protection through monitoring of press feed signal and feed completion.

- High Performance: The performance is tuned to suit the specific requirements. Feed length accuracy better than +/- .003″

Typical 600f72 set up

a=240 in/s/s,, feed angle = 180 degrees, maximum uncoiler speed = 80 fpm

20 spm —- 45″ progression

30 spm —- 28″ progression

40 spm —- 20″ progression

h) Safety circuits. The control is wired with dual path Emergency Stop and Gate Monitor circuits. The control relays are Safety rated contactors with external reset.

- On Emergency stop, all high voltage power is disconnected from drives and hydraulic power unit, and 120vac and 24vdc power is disconnected from all solenoid valves, control power remains connected.

- On Gate monitor circuit open, the system will allow manual functions, but will prevent automatic functions.

System #15690

Requirement: Uncoil 2 steel coils at the same time

Material: Steel 30,000 psi

Thickness: 20Ga

Width: 2″-15″

Coil weights: 1500 lbs

Process speed: 200 fpm

Press speed: 120spm

Proposed Solution:

Dual UNCOILER model T15M16

- CAPACITY 1,500 lbs. per spindle

- MAXIMUM WIDTH 16″

- COIL ID. RANGE 12″ to 21″

- COIL MAXIMUM OD 60” typical

- dual spindle uncoiler,

- 3/4 hp DC spindle drive on each spindle

- Drives are controlled manually for jogging the coil, and automatically by the loop controlers during run.

MECON model T15M16 Tandem spindle uncoiler with 2 complete 15M uncoiler spindles

Requirement:

Material: Steel 70,000 psi

Thickness: 3/8”

Width: 8”

Coil weight: 10,000 lbs

Process speed: 34 fpm

Feed length: 8”

Press speed: 50spm

Pass line height: 46″

System voltage: 575v, 3-phase, 60 Hz;

Proposed Solution:

COILCRADLE – STRAIGHTENER: 200CCS18

- 6str18 straightener upgrade

- motorized straightener adjustment screw

- adjust side guide rolls side plate rolls

- drive upgrade to 20 hp

- laser loop control

- extra heavy duty threading

- end pivot threading table

FEEDER: 600F18 with Antibackup brake

- Floor base- power pass line adjust

- Screw adjust sideguide with offset adjust