- Stacking Pallets

- Part Conveyors

- Multi-Function Pendant

- Feeder Exit Table

- Side Shift Base

- Laser Loop Control

- Coil Car

- Upenders

- Threading Table

- Hold Down Arm

- Material Guidance

- Shear

Die Feeder

- Don’t throw away the tail material or struggle with it to get it out of the way, use it to the end.

- The die feeder consists of two hardened pinch rolls which are closed by air cylinders and driven by an air motor.

- The feeder is intended to be installed between the main servomotor driven feeder and the tooling.

- When the end of the material exits the servofeeder, then the die feeder rolls are closed onto the material and the operator will use the air motor drive to push the material forward into position for the next press cycle.

- Continue to manually position the material, then cycle the press until the material exits from the die feeder.

- The feeder is designed to be mounted directly on the tooling or onto the bolster when supplied with the optional base.

- Build to suit with passline adjustment. Final design to suit application.

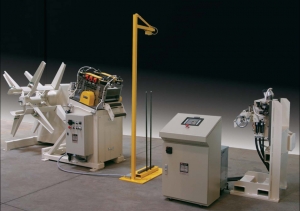

Coil Car with Narrow Coil Keeper Arms

- Typical power lift of 20″, 110” travel 1,000 to 60,000 lbs.

- Dual scissor stabilizer to support top of car when loaded off center

Material Guidance systems

- Screw adjust side side guides help hold the material square and centered as it enters the straightener.

- Screw adjust side guides are selfcentering, roll position is set by hand wheel.

Multifunction pendant

- Multifunction pendant (replaces standard 2 button jog pendant)

- Mode select: Setup- Manual- Automatic, Reset, Feeder Auto start, Feeder Auto stop, Jog Reverse, Jog Forward

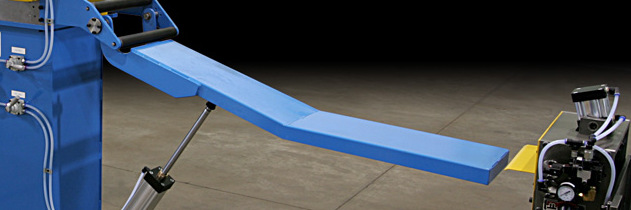

Coil System Threading Table

- Eliminate the need for the operator to carry the start of the material from the coil to the straightener

- Safe material handling operation

Mecon Laser Loop Control System:

- Controls the uncoiling process to supply material into an accumulation loop at a rate sufficient to meet or exceed the demands of the machine pulling material from the loop.

- Provides a simple method of setting the operating limits, the operating parameters, and the mode of the loop control.

- Allows the uncoiling process to run without abrupt changes in speed.

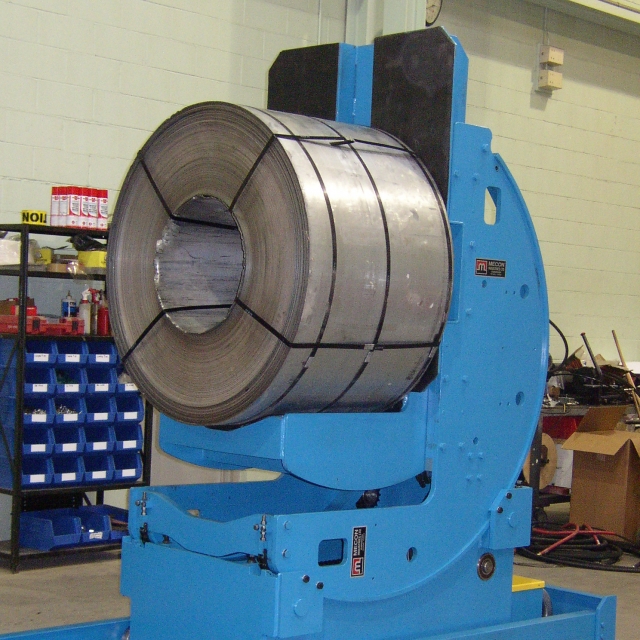

Coil Upender

- Easy and safe way to upend not only metal coils, but also molds, dies and other heavy and bulky loads.

- Available 1,000-60,000lbs standard, custom to you requirement.

Shear

- Modular construction to allow easy integration

- CRU-WEAR High chrome, high carbon tool steel shear blades with 4 cutting edges 1/2 x 3″.

- CYCLE TIME less than 1.5 sec.

Perimeter Safety Fencing

- 2.5″ sq. posts lagged to the floor.

- Spaces between are posts fitted with panels 1.5 x 1.5 angle frame and 10 ga. x 1 x 1 welded wire.

- Fixed panels are bolted in place. Any fixed panel may be removed by unbolting.

- Sliding or hinged doors may be placed anywhere in the perimeter/

- Telescoping doors and light curtains available

- Fully programmable multiple Safety Zones

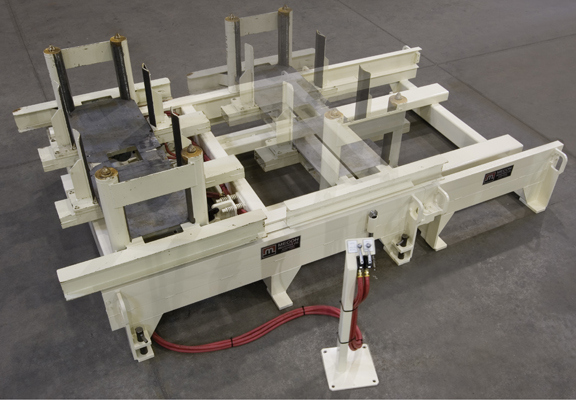

Stacking Pallets

- Adjustable posts to align blanks for stacking.

- Sub frame with cross tubes for lift truck forks and corner posts for stacking.

- Guide posts mounted on Tee Slotted bars for positioning

- Guide posts mounted on sliding and pivoting bases.

- Custom designed for your requirement.

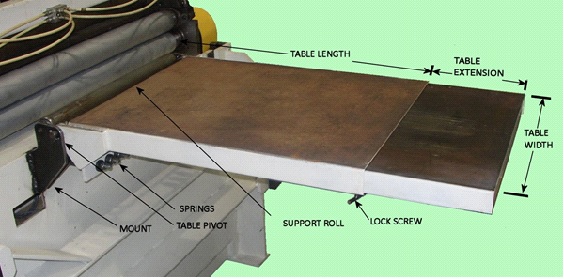

Feeder Exit Table

- This version has a solid top, spring suspension, and is extendable

- Options: mount for strip lubricator, roller top, nylon top, …

- Design to suit site requirements.