Typical system requirements and proposed solutions:

#15570 20Klbx40″ Press Feed Line#15849 20Klbx60″ CTL Line

#3120 50Klbx72 Conventional Press Feed System

LINE #11 System #15570

20,000LBS x 40″ Press Feed Line

Requirement:

1 Coil Feed System for .312″ material.

- 20,000 lb x 40” wide capability

- Material thicknesses: up to .312″, see below

- Material width: 40″ max.

- Press speed: 60 SPM

- Feed length: 12″ Max

- Feed angle: to be determined

- Coil OD.: 72″ max.

- Coil ID.: 18-22″

- Passline: 54″ to 57″

- Quick coil changeover

Proposed Solution:

The system offered is comprised of a combination coilcradle-feeder-straightener. The coil cradle and feeder-straightener are both driven by servodrives. The system is designed to run with no loop, the cradle drive and straightener drive are matched electronically.

The servo-drive responds to the press cam switches, and feeds an exact amount each press stroke.

Model 200CSF40 Coil Staging Ramp Cradle Uncoiler, Feeder-Straightener with Servo Pilot Release

-CAPACITY 20,000 LB.

-MAX. OD 72″

-MIN. ID 18″

-MAX. THICKNESS 0.312″

-PASSLINE HEIGHT 52″ TO 58″ POWER ADJUSTMENT

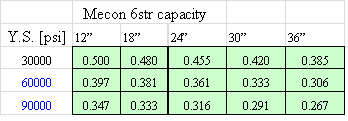

Based on review of the most difficult materials on the specification list we recommend the 6STR40 straightener.

Machine frame and drive sizing will match the straightener capacity listed for the 6STR40 series straightener.

COMPONENTS.

Coil Storage ramp:

-The coil is loaded onto a coil storage ramp waiting for the current coil to run out.

-The ramp raises to create a down slope for the coil to roll toward the cradle rolls in the run position.

Cradle:

– The coil is supported on 2 hardened cradle rolls

– Cradle rolls are driven by a servo-gearmotor

– Cradle side plates are self-centering and are power adjusted.

Threading System:

– the coil rolls into the cradle and is cushioned by the peeler roller as it reaches the cradle rolls.

– the peeler roller is then used to bend the start of coil away from the coil and deflect it into the straightener.

Feeder-straightener:

-A six roll straightener is used to provide easier control and adjustment of the material. The last roll allows the operator to fine tune the strip up or down more simply than with 7 or 5 roll style straighteners.

-rolls are 1045 steel, 6.000″ diameter, induction hardened to 56-58 Rc, and diameters are precision ground. Bearings are Heavy Duty needle rollers running on hardened inner races with seals.

-The upper 3 rolls of the straightener are not driven and are individually adjustable.

-Straightener rolls are adjusted by hydraulic motors, roll position is indicated by digital counters with .001″ resolution.

-Feed rolls are 1045 steel, 6.000″ diameter, induction hardened to 56-58 Rc, precision ground, shot peened and chrome coated for excellent wear resistance and grip.

-2 entry feed rolls, upper and lower roll driven, grip the strip to drive material thru straightener without resetting. Upper roll is lifted/lowered by 2 hydraulic cylinders 4″ diameter. Rolls open up to 1″ clear for easy threading.

-2 exit feed rolls, upper and lower roll driven, grip the strip to drive material thru straightener without resetting. Upper roll is lifted/lowered by 2 hydraulic cylinders 4″ diameter.

-entry ramp rolls support material to ensure smooth flow into straightener.

-hardened vertical side guide rolls align the strip to the tooling. Rolls are supported on steel slides and locked into position individually.

-The rolls are driven by a Servo-gearmotors.

-Centralized automatic lubrication system for the cradle, straightener and feeder rolls.

Lift system:

– The machine is supported by worm screw jacks. The jack feet act as levelling pads and rest on bars attached to the floor, or side shift frame.

2 guide posts mounted to the front mount plate prevent side movement.

Controls:

Drives cabinet: Main disconnect, contactors, fusing, controls and drives.

Machine mounted operator station:

Control switches, and Touch screen HMI for Length, speed, and parameter inputs.

Multifunction pendant:

AutoStart, AutoStop, Feed Index, JogREV, JogFWD, Mode Select, Front shift Left/Right, Rear Left/Right

Optional Pilot release of straightener rolls. (at 40 spm requires 60deg pilot angle)

The upper rolls frame is connected by 2 shafts with eccentric pivots to ensure accurate holding of the roll position. The shafts are rotated by a servomotor. Pilot release timing is controlled by press camswitch.

System #15849

210,000LBS x60″ CTL Line

Requirement:

Cut to length system, Single uncoiler with Coil cart

- 10,000 lb x 48” wide capability

- Material thicknesses:.015”-.060”

- Material: galvanized, galvalume, cold-rolled steel, stainless steel (304, 316, 409, 430, AL29-4C, other) Note: Majority is SS material

- Min/Max coil width: 24”/48”

- Existing available floor space to work within: 35ft long x 10ft wide.

- Min/Max cut length: 9”/51”

- Production rate: 1500 blanks per hour (22” avg cut length)

- Loop control sensor

- Threading table

- Powered straightener

- Servo roll feeder (feed roll accuracy of +/-0.002”)

- Precision Shear

- Shear blade material with high wear resistance (i.e. Cru-wear)

- Minimal shear blade change time (

- 5’ x 5’ Blank stacking system (that will not damage sheared edge) Blanks muststack directly onto existing metal pallets used for laser welder. (See below).

- Quick/easy coil changeover

Important Considerations:

Tight tolerance on length.

Out of square causes problems

Flatness

Rewinding of partial coils

Coil Handling streamline and automate

Stacking system, even stacking very important

Minimize marking.

Proposed Solution:

Coil car – 200cc with Coil keeper arms

- 20,000lbs capacity, 19″ vertical lift, 120″ travel

Uncoiler – 200m60

- 20,000lbs. capacity

- 60”, 4 segment mandrel with hydraulic expansion 18” to 22” diameter

- Overarm with idle wheel

- 100” travel base with tractor drive

- Overarm with idle wheel

- End Pivot, hydraulic lift threading table EPH 60 x 150

- The threading table is used to eliminate the need for the operator to carry the start of the material from the coil to the straightener .

- Extended entry conveyor with ramp .

- 2 sets side guide rolls with centering screw adjust .

- Coil centerline laser .

Combination Feeder Straightener – 4str60 .

- 11 hardened and ground rolls running on precision needle bearings,

- Bearings lubricated from centralized manifolds (hand lubricated)

- Entrance and exit pinch rolls; air actuated, lower rolls driven,

- 2 entrance pinch rolls, 4.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading,

- 2 exit pinch rolls, 4.000″ diameter, open for threading, close for running, servo drive with 575v to 440v transformer

- Flex system control HMI with I/O for shear control

- Exit side guide rolls with centering screw adjust .

Shear – 08hs60

- MAXIMUM WIDTH 60″

- THICKNESS .080″ AT 60″ WIDE 60,000 UTS MILD STEEL

- THICKNESS 0.004″

- CYCLE TIME 2 seconds

Requirement: 50,000 lbs. x 72” wide Steel coiled material to be stored, uncoiled, straightened, and fed into a press.

Maximum coil weight: 50,000 lbs.

Min/Max coil I.D.: 19 ½” -24 ½”

Max coil O.D.: 72”

Press: PTC

Passline ht: to be determined

Feed angle: 180 degrees

Material: .020″ to .236″ (6mm) mild steel and hsla,

Material: .08 x 60″ 50ksi ys steel

Material: .120” x 72” (3 mm) x 50 ksi,

Material: .177” x 56” x 50 ksi ys HSLA

Performance: 15” x 48 spm, 24” x 30 spm

Power supply: 480 volt, 3PH, 60Hz

Air supply: 80 psi

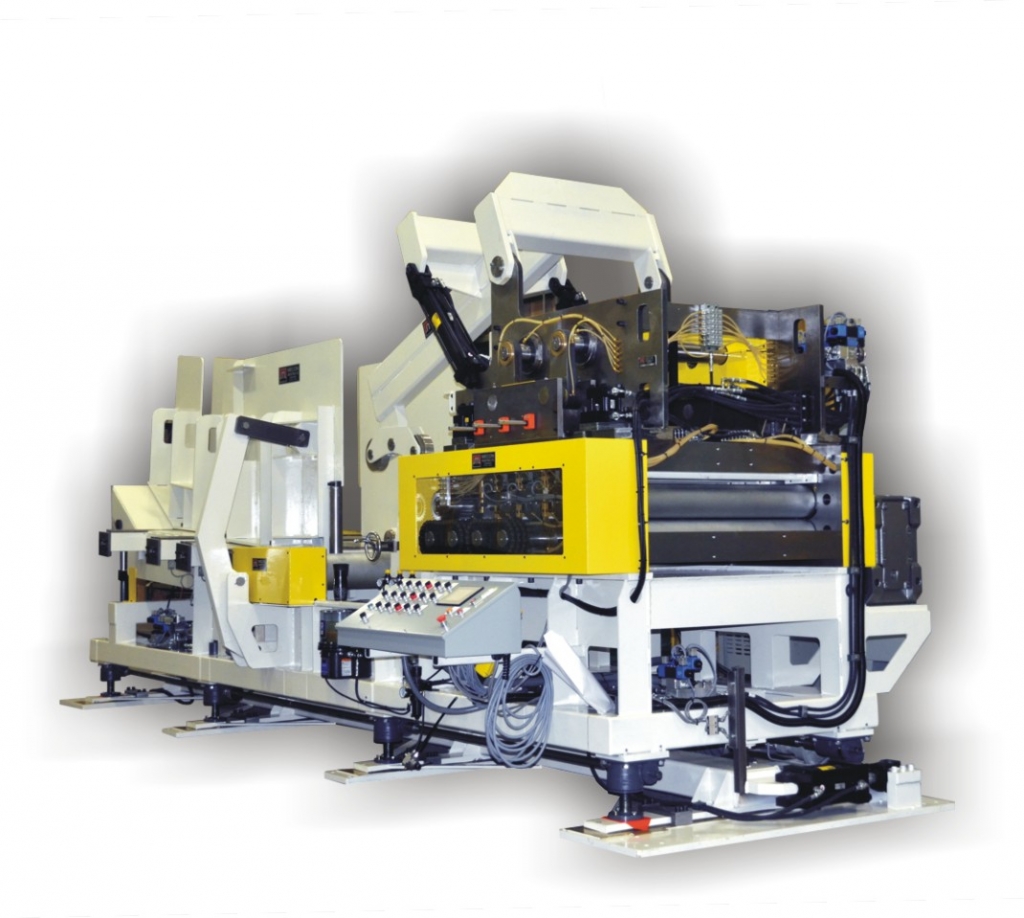

Proposed Solution: System Proposal – coil car, uncoiler, power straightener, accumulation loop, feeder.

a) Coil car model 500cc with power top rolls:

- A coil car with power lift of 20″ and power travel.

- The car will travel on tracks to transfer the coil from the park position to the uncoiler, or from the uncoiler back for storage. The coil rests on non-powered rollers.

- The rolls are used to aid in threading thicker materials into the straightener. Traverse, and lift functions are controlled manually from a central control station.

b) Uncoiler model 500btj72. ( capacity 50,000 lbs x 72” with spindle end support)

- The uncoiler has an air brake to maintain coil tension during processing.

- A hydraulic motor, and clutch for jogging coil. Jog speed 4 rpm.

- Upgrade to heavy duty back tension brake with coil diameter sensor to maintain constant tension during unwind of coil.

- The mandrel is 4 segments, with wedge style expansion and is hydraulically expanded/retracted.

- Inside diameter range of 19.5 to 24″.

c) Coil over arm with power wheel: Peeler / coil breaker.

- The over arm clamps onto the coil to contain the coil end when the straps are cut.

- The wheel is powered by a hydraulic motor and drives the coil to thread the start of the coil to the input pinch rolls of the straightener.

- The Peeler extends to contact the coil and guide the start of the coil.

- The coil breaker lifts to press the strip against a flattenning block on over arm and thus de-kink the start of the strip. This allows easy threading of steel into straightener.

d) Straightener model 5str72-bu: Series straighteners have:

- 11 hardened and ground rolls running on precision needle bearings, bearings lubricated from centralized manifolds (hand lubricated)

- Entrance and exit pinch rolls; air actuated, lower rolls driven.

- 2 entrance pinch rolls, 5.000″ diameter, close onto material to drive starting edge thru straightener, not required to change straightener settings for threading.

- 2 exit pinch rolls, 5.000″ diameter, open for threading, close for running.

- 7 straightenning rolls, 5.000″ diameter, 4 lower rolls all driven, 3 upper rolls idle.

- Upper rolls motorized individual adjustment, position shown on .001″ graduation counters.

- Straightener drive: Variable Frequency AC Motor control with AC induction motor, and brake.

speed 0-80 fpm. infinitely variable. These drive systems give very smooth acceleration and deceleration with no sudden shocks to the material or drive components, and thus extend machine life and limit material marking. - In automatic mode a sonar unit senses the height of the material in the loop between the straightener and the feeder.

- The sensor signals the drive to speed up or slow down to maintain the loop automatically.

- The uncoiler brake is provides back tension to limit coil overrun and to help prevent coil slack.

- n manual mode the speed is set at a low speed and forward or reverse movements are selected by pendant mounted switches.

- HD Support rolls: The drive system will be increased to 40 hp to match the higher capacity of the straightener. Each straightener roll is supported by rolls to limit roll deflection when processing heavy materials. Lower support roll positions are fixed and not adjustable. Upper support rolls travel with the straightener roll during adjustment.

- Material guidance: Coil peeler and breaker guide material into straightener.

- Entrance vertical guide rolls to track the material.

- Exit ramp rolls support strip as it exits straightener and drops into loop.

| Model 5str72-40 hp with support rolls | ||||||

|---|---|---|---|---|---|---|

| 24" | 36" | 48" | 60" | 72" | ||

| yield 30,000 psi | inches | .375" | .375" | .290" | .250" | .210" |

| yield 60,000 psi | inches | .316" | .283" | .245" | .211" | .177" |

| yield 90,000 psi | inches | .283" | .253" | .219" | .189" | .158" |

System Summary:

a) COIL CAR: MODEL #500CC .

- 20″ lift .

- Keeper arms .

- power rolls .

b) UNCOILER: MODEL 500BTJ .

- 72″ mandrel .

- side shift uncoiler .

- xHd btj base .

- coil diameter brake control .

c) THREADING: MODEL HD72 .

- motorized overarm wide roll std

- coil breaker table std

- peeler arm std

d) STRAIGHTENER: MODEL 5STR72 .

- 40 HP VFAC drive .

- power adjust strnr .

- Stnr support rolls .

- main transformer .

- Sonar loop control .

e) END PIVOT THREADING TABLE:

f) SYSTEM INTEGRATION:

g) FEEDER: MODEL 600F72-IHD

- floor base power elevation .

- 3 ph. isol. transformer

h) Estop and Gate monitor circuits .

- Hydraulic cylinders actuate the table. The table lifts to support material between the straightener and the feeder as the beginning of the strip is being jogged to the feeder.

- Table length is dependent on the loop geometry, which is related to the maximum material thickness, material strength and feed length.

f) Straightener control station and integration:

- Contains the controls for the coilcar, uncoiler, overarm/peeler/breaker station, the straightener, and the threading table.

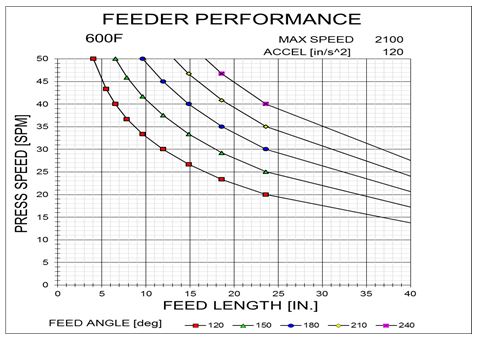

g) Feeder model 600f72-IHD: The feeder is a floor mounted machine with a press adapter bracket, a seperate control console and a remote jog pendant. The press adapter bracket rigidly attaches the feeder to the press. The jog pendant allows the operator to walk with the material when threading.

- Feed Rolls: The rolls are 73.5″ face width x 6.000″ diameter. They are hardenned, precision ground and 100rms chrome surfaced for excellent grip and wear resistance.

- Upper and lower rolls are both driven.

- Passline Adjustment; Passline height is adjusted by a powered elevator, total adjustment 12″.

- Pilot release: The feed rolls are pnuematically lifted and lowered. The pilot release circuit is signalled by a press cam to lift the rolls and lower the rolls to release the material.

- Anti-Backup brake mounted on the motor is standard. The brake is spring engaged and is on anytime the power is off the servo motor. When the pinch rolls are contacting the strip, the brake will not allow the material to slip back into the loop.

- Servo-Drive: An Indramat high performance brushless AC servosystem drives the feed rolls. It is conservatively rated and is capable of peak torques well in excess of the rated torque.

- The servo motor is mounted to a servo quality “zero” backlash gearbox, and mounted under the feed rolls. A high performance Gates Polychian drive connects the gearbox output shaft to the lower feed roll. Components Mkd Motor, Alpha Sp gearbox.

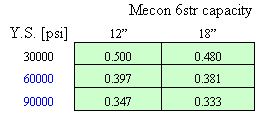

- Computer Control: An Indramat motion control – Mecon OCS control runs the servodrive. It is very flexible. Program parameters, speed and feed length, etc. are input directly through keypad. Displays operating mode, error and system diagnostics, etc.

- Very fast setup of next job.

- Die and press protection through monitoring of press feed signal and feed completion.

- High Performance: The performance is tuned to suit the specific requirements. Feed length accuracy better than +/- .003″

Typical 600f72 set up

a=240 in/s/s,, feed angle = 180 degrees, maximum uncoiler speed = 80 fpm

20 spm —- 45″ progression

30 spm —- 28″ progression

40 spm —- 20″ progression

h) Safety circuits. The control is wired with dual path Emergency Stop and Gate Monitor circuits. The control relays are Safety rated contactors with external reset.

- On Emergency stop, all high voltage power is disconnected from drives and hydraulic power unit, and 120vac and 24vdc power is disconnected from all solenoid valves, control power remains connected.

- On Gate monitor circuit open, the system will allow manual functions, but will prevent automatic functions.

Requirement: Uncoil 2 steel coils at the same time

Material: Steel 30,000 psi

Thickness: 20Ga

Width: 2″-15″

Coil weights: 1500 lbs

Process speed: 200 fpm

Press speed: 120spm

Proposed Solution:

Dual UNCOILER model T15M16

- CAPACITY 1,500 lbs. per spindle

- MAXIMUM WIDTH 16″

- COIL ID. RANGE 12″ to 21″

- COIL MAXIMUM OD 60” typical

- dual spindle uncoiler,

- 3/4 hp DC spindle drive on each spindle

- Drives are controlled manually for jogging the coil, and automatically by the loop controlers during run.

MECON model T15M16 Tandem spindle uncoiler with 2 complete 15M uncoiler spindles

Requirement:

Material: Steel 70,000 psi

Thickness: 3/8”

Width: 8”

Coil weight: 10,000 lbs

Process speed: 34 fpm

Feed length: 8”

Press speed: 50spm

Pass line height: 46″

System voltage: 575v, 3-phase, 60 Hz;

Proposed Solution:

COILCRADLE – STRAIGHTENER: 200CCS18

- 6str18 straightener upgrade

- motorized straightener adjustment screw

- adjust side guide rolls side plate rolls

- drive upgrade to 20 hp

- laser loop control

- extra heavy duty threading

- end pivot threading table

FEEDER: 600F18 with Antibackup brake

- Floor base- power pass line adjust

- Screw adjust sideguide with offset adjust